Jan 22, 2026

In industrial fluid systems, the globe valve is well known for precise control and reliable sealing. However, in low-pressure, high-flow applications, these same valves often introduce limitations that are not immediately obvious during the design stage.

Low-pressure systems operate with limited available pressure differential. When large flow rates are required, even small increases in flow resistance can significantly reduce system performance.

In high-pressure systems, localized pressure losses may be negligible. In contrast, low-pressure systems—such as cooling water loops or gravity-fed pipelines—have little margin to absorb additional losses.

In these conditions, excessive valve pressure drop can lead to reduced flow rate, increased pump load, and unstable downstream operation.

A globe valve forces fluid to change direction inside the valve body. This bent flow path enhances controllability but also increases turbulence and energy loss.

As flow rate rises, these losses grow disproportionately, making globe valves less suitable for applications where minimal pressure drop is critical.

In real installations, globe valves used in low-pressure, high-flow pipelines often remain fully open, yet still restrict flow. The result is higher energy consumption and reduced system efficiency—not because of valve failure, but because of structural flow resistance.

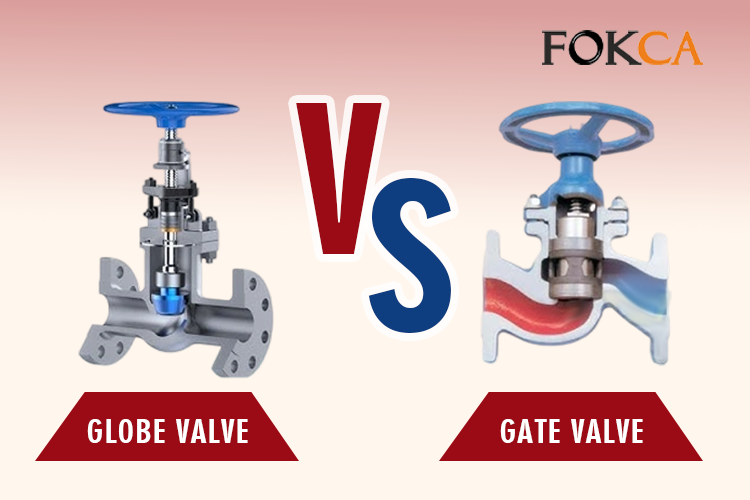

| Valve Type | Flow Direction | Relative Pressure Drop | High-Flow Suitability |

|---|---|---|---|

| Globe Valve | Redirected | High | Limited |

| Ball Valve | Straight-through | Low | Excellent |

| Gate Valve | Straight-through | Very low | Good |

Globe valves require careful evaluation in:

◆ Low-head pumping systems

◆ Gravity-driven pipelines

◆ Main distribution lines

◆ Energy-efficient continuous processes

In these cases, even a fully open globe valve can become a flow bottleneck.

For engineers, buyers, and distributors, valve selection should align with system priorities. When flow efficiency matters more than fine control, low-resistance valve designs are often the better choice.

Understanding where a globe valve excels—and where it does not—is key to building stable, efficient systems.

(FK9025)

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Does Nylon Tubing Become Brittle in Low-Temperature Environments

Does Nylon Tubing Become Brittle in Low-Temperature Environments

You May Interest In

Dec 12, 2025 Blog

What Is a Globe Control Valve?

Dec 11, 2025 Blog

Two ways for a globe valve to be bidirectional

Dec 10, 2025 Blog

How Does a Manual Globe Control Valve Work?

Dec 08, 2025 Blog

Can a Globe Valve Be Used to Control Steam Pressure

Dec 08, 2025 Blog

How Does a Globe Valve Work

Dec 04, 2025 Blog

How to Identify Gate Valve and Globe Valve

Dec 09, 2025 Blog

Working Principle of Check Valves

Dec 06, 2025 Blog

How to check pneumatic solenoid valve?

Dec 04, 2025 Blog

How does a single solenoid valve work?

Dec 03, 2025 Blog

What is double acting solenoid valve?

Dec 02, 2025 Blog

How to clean a pneumatic solenoid valve?

Dec 01, 2025 Blog

How to Wire and Install a Pneumatic Solenoid Valve?

Nov 30, 2025 Blog

How to select pneumatic solenoid valve?

Nov 29, 2025 Blog

Operational Mechanism of Pneumatic Solenoid Valves

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap