Dec 02, 2025

As a professional pneumatic solenoid valve manufacturer, we frequently receive these kinds of questions from our customers. Today, we'll explain in detail how to properly clean pneumatic solenoid valves, and here are very clear steps you can follow.

Regular cleaning and maintenance of a pneumatic solenoid valve are essential for ensuring reliable operation, extending service life, and preventing malfunctions in pneumatic systems.

The routine maintenance of pneumatic solenoid valves is by no means a trivial or dispensable task. It is a critical link in ensuring the reliable, efficient, safe, and economical operation of the entire pneumatic system and even the production process. It is a low-investment, high-return effort that can achieve the highest equipment reliability, the longest service life, the optimal product quality, and the greatest safety assurance at the lowest cost.

If you are unsure when a pneumatic solenoid valve needs cleaning, here are some signs that it may require cleaning:

Abnormal or Unresponsive Operation:The valve responds slowly, lags, or cannot fully open/close. The spool may be stuck or move irregularly.

Air Leakage:Obvious leakage occurs at the valve body or connections, affecting system pressure and efficiency.

Contamination Blockage:Dust, oil, water, or metal particles enter the valve, causing internal passage blockage.

Abnormal Noise:The valve makes unusual “clicking” or buzzing sounds during switching, possibly due to internal dirt or spool friction.

Periodic Maintenance for Long-Term Use:Even industrial-grade pneumatic solenoid valves require regular cleaning according to the equipment maintenance manual to extend service life.

Keep your pneumatic solenoid valve in top shape by cleaning it with solvents like carb cleaner or compressed air.

Mild Degreaser:Non-corrosive to aluminum and copper, and safe for rubber seals; suitable for removing oil stains, dust, and light grease residues.

Isopropyl Alcohol:Provides quick cleaning of the valve core, coil housing, and fittings without leaving any residue.

Mild Neutral Cleaner:Appropriate for cleaning solenoid valves with diaphragm structures or plastic valve bodies.

Clean Dry Air:Although not always highlighted as a “cleaning agent,” the use of clean, dry, oil-free compressed air is essential, as it effectively removes metal chips, dust, and fine particles, and clears internal passages.

The following cleaning process primarily uses anhydrous ethanol, kerosene, and Mild cleaning agent.

Step 1: Preparation work

Safety first: Ensure that the power and air sources of the entire pneumatic system are completely turned off and disconnected.

Disassemble the valve body: Remove the solenoid valve from the system pipeline or base.

Prepare tools and materials: Prepare suitable screwdrivers, hex wrenches, anhydrous ethanol (or industrial alc ohol), kerosene, soft bristled brushes, lint free cloth (such as dust-free cloth), and compressed air.

Step 2: Carefully disassemble

Separate coil: Unscrew the fixing screws and carefully separate the electromagnetic coil part from the valve body first. Attention: The coil is an electrical component and must not come into contact with any liquid.

Disassemble the valve body: Remove the screws on the valve body and separate the valve cover from the valve body. At this point, you will see the internal valve core (or slide), spring, and seal.

Record order: It is recommended to place the parts in the order of disassembly or take photos for proper reassembly. Pay special attention to the position and direction of the small spring.

Step 3: Cleaning and Inspection

Soaking and Brushing:

Soak metal parts such as valve cores and springs in anhydrous ethanol or kerosene.

Gently brush the surface of the parts with a soft bristled brush, especially the shoulders and grooves of the valve core, as well as the internal holes of the valve body, to remove all oil sludge and impurities.

Key: Use a dust-free cloth dipped in cleaning agent to wipe the inner wall of the valve body and valve cover.

Protection seal:

Rubber seals (such as O-rings) are best cleaned separately with a mild cleaning agent or replaced directly. Avoid prolonged exposure of seals to highly corrosive solvents to prevent aging and deformation.

Comprehensive inspection:

After cleaning, carefully inspect the valve core and inner wall of the valve body for scratches, wear, or rust. Any minor damage can lead to internal leakage.

Check if the seals are intact, free from damage, deformation, or loss of elasticity. If there is any damage, be sure to replace it with a new one.

Step 4: Drying and Assembly

Thoroughly dry:

Use dry compressed air to thoroughly dry all parts, especially the precision holes inside the valve body.

Ensure that there are no liquid residues or fabric fibers.

Lubrication and assembly:

Apply a small amount of pneumatic system specific lubricating grease (such as silicone grease) on the valve core and seals. This can reduce wear, prevent corrosion, and help seal.

Carefully reinstall all parts in the reverse order of disassembly. Ensure that the valve core is installed in the correct direction, the spring position is correct, and all screws are tightened evenly.

Step 5: Testing

Reinstall the cleaned solenoid valve onto the system.

First, connect the air source and check for any leaks at each interface.

Connect the power again and test whether the valve switching is smooth and whether the cylinder action is normal through manual or automatic control.

Maintaining solenoid valves is crucial for their longevity and performance. Here are some best practices and tips on how to keep your solenoid valves in top shape:

◆ Proper Installation and Sizing:Make sure the valve is installed correctly and the right size is used for the system.

◆ Periodic Functional Testing:Regularly check if the valve opens and closes properly.

◆ Electrical System Inspection:Check the wiring, connectors, and coil to ensure there are no loose parts or damage.

◆ Troubleshooting and Quick Fixes:Find problems early and fix small issues before they become big ones.

◆ Regular Cleaning and Maintenance:Keep the valve clean and perform basic maintenance to ensure long-term reliable operation.

Other websites related to manufacturing:

Cleaning is a necessary operation before installing a pneumatic solenoid valve. The specific installation steps are as follows:

◆ Inspect Valve and Pipeline

◆ Secure the Valve Body

◆ Connect Air Pipe or Pipeline

◆ Electrical Connection

◆ Air Supply Testing

◆ Final Inspection

Cleaning of Pneumatic Solenoid Valves involves removing dirt, deposits, or contaminants from the valve body, valve core (piston), and seals.

Below is the schedule table for inspection and cleaning of solenoid valves:

| Environment | Inspection Items | Inspection Frequency | Cleaning Items | Cleaning Frequency |

|---|---|---|---|---|

| General Industrial | Function, leakage, electrical, appearance | Monthly | Disassemble valve to clean piston, seals | Every 6–12 months |

| High Dust / High Contamination | Same as above | Every 2 weeks | Same as above, can be more frequent | Every 3–6 months |

| Clean / Food / Pharmaceutical | Function, leakage, electrical | Weekly | Disassemble valve to clean, sanitize, replace seals | Every 1–3 months |

(9016)

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Dec 01, 2025 Blog

How to Wire and Install a Pneumatic Solenoid Valve?

Dec 06, 2025 Blog

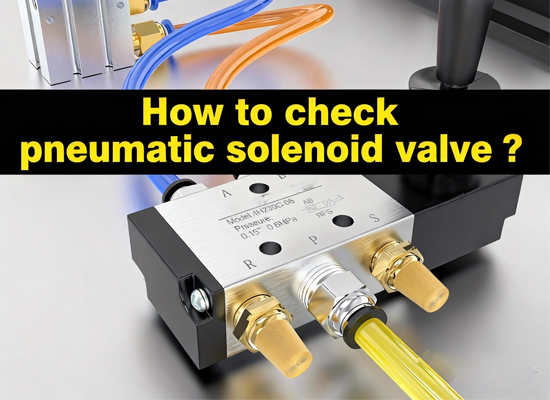

How to check pneumatic solenoid valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap