Jan 28, 2026

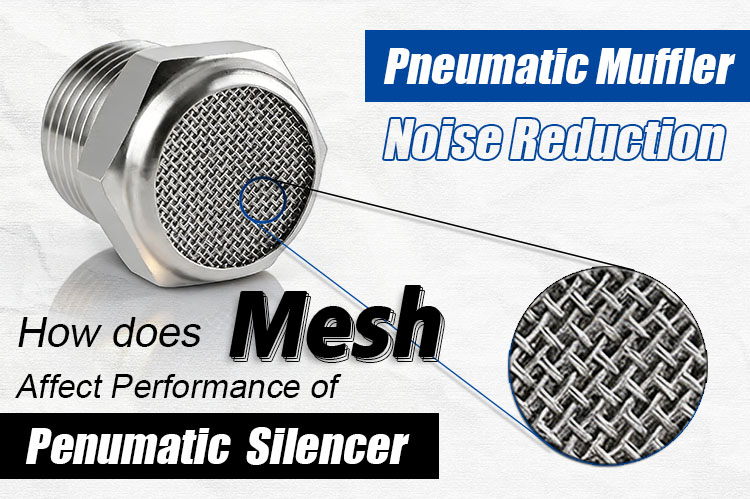

In modern industrial production, pneumatic systems have become the preferred choice for industries with stringent environmental requirements such as food packaging, pharmaceutical manufacturing, and electronic board assembly due to their clean and pollution-free characteristics. However, the noise generated during the exhaust process of pneumatic systems has long been a concern for engineers. It is precisely this challenge that makes pneumatic silencers a critical and indispensable component in pneumatic systems.

Silencers are not just components that "keep equipment quiet." In fact, the selection of silencers directly impacts the operational efficiency, energy consumption, and service life of the entire compressed air system. An improperly selected silencer can lead to excessive system pressure drop, significant energy waste, and even cause failures in downstream equipment, resulting in substantial losses for the production line.

When selecting pneumatic silencers, one of the most common and important indicators is filtration accuracy. It directly reflects the filtration capability and noise-reduction capabilities of the silencer. However, contrary to popular belief, filtration efficiency is not always better when higher!

First and foremost, it is essential to understand that the "filtration" target of a silencer is sound waves. Its internal porous structure (typically made of sintered materials or metal/plastic mesh) breaks down large streams of airflow into countless tiny, low-speed vortices. As sound waves pass through these narrow and tortuous channels, their energy is converted into heat through friction and damping, thereby achieving noise reduction.

Therefore, the filtration precision of a silencer only represents its ability to filter and reflect sound waves; it cannot filter out micron-rating oil mist and dust like an air filter.

Moreover, while improving noise reduction capability, higher filtration precision also comes with necessary "trade-offs," such as reduced air flowability and increased pressure drop. For specific comparisons, please refer to the table below:

Characteristic | Low Precision | High Precision |

Port Size | × | √ |

Air Flowability | √ | × |

PressureDrop | √ | × |

Noise Reduction | × | √ |

Dust Resistance | × | √ |

Clogging Risk | √ | × |

Maintenance Cycle | √ | × |

Therefore, the selection of filtration accuracy is essentially a typical trade-off issue that requires careful consideration based on the actual application scenario.

For example, in applications such as laboratories, medical equipment, food and pharmaceutical manufacturing, and chip production lines, where strict control of noise and environmental cleanliness is required, high-precision silencers are suitable.

In contrast, in ordinary industrial environments or pneumatic systems equipped with front-end air treatment units, lower-precision silencers, while offering relatively poorer noise reduction, can provide better energy efficiency and longer replacement cycles.

Some product specifications may not directly indicate "filtration accuracy" but instead use "mesh count" as a representation. Understanding the relationship between these two is crucial for proper selection.

"Mesh size" is a traditional unit used for particle size screening, typically referring to the number of openings in a one-inch length of screen. For example, a 100-mesh screen means there are 100 openings per inch.

Although mesh count is not an international standard, it remains widely used in the industry due to its long history and convenience. When selecting silencers, we need to approximate the relationship between mesh count and filtration precision.

Please note: Since "mesh size" only specifies the number of openings and does not regulate the diameter of the mesh wires, even with the same mesh count, the actual pore size and filtration precision of screens from different manufacturers or made of different materials may vary slightly. Therefore, the conversion between mesh size and filtration accuracy can only be approximate.

Mesh Size | ≈ | Filtration accuracy (Microns) |

20-40 | 850-350 | |

60-80 | 250-180 | |

100 | 150 | |

150 | 106 | |

200 | 75 | |

325 | 45 |

In general, a higher mesh count corresponds to higher filtration precision and better noise reduction, but it also comes with a greater system pressure drop.

The selection of pneumatic mufflers is an art of balance, requiring engineers to comprehensively consider technical parameters, application scenarios, and economic factors.

Proper selection not only effectively reduces noise pollution but also ensures the efficient and stable operation of pneumatic systems, creating long-term value for enterprises.

We hope this article helps you make more scientific and rational decisions in your future silencer selection work.

Fokca (Fescolo) is a professional pneumatic cylinder manufacturer and supplier. As a leading Chinese supplier in this field, we specialize in providing high-quality, precision-engineered cylinders designed for a variety of applications.

As a manufacturer, we produce a wide range of silencers utilizing diverse materials, specifications, and models, including plastics, brass, and stainless steel. Our products are available with various thread standards and sizes, such as G, PT, and NPT, ensuring compatibility with diverse operational requirements across multiple working environments. In addition to our standard product line, we possess strong professional customization capabilities to meet specialized needs.

If you have any requirements, please feel free to visit our air treatment unit product page for more information. Additionally, you can explore our Blog section, where we provide a range of resources including videos, images, articles, and drawings to help you better understand pneumatic products.

(FK9009)

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap