Oct 15, 2025

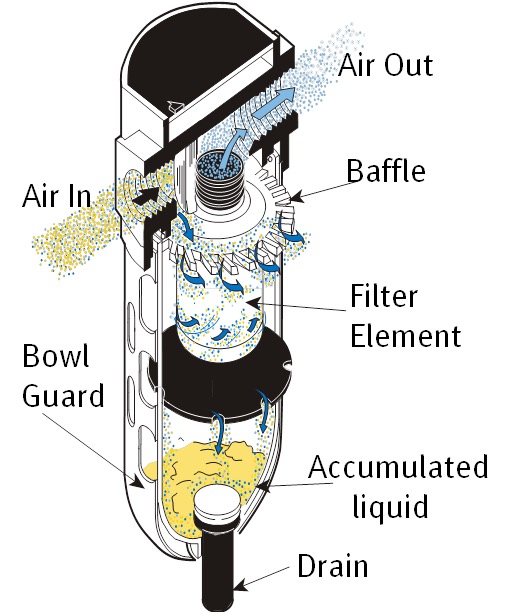

When it comes to compressed air, the most important point is that it is not pure. A pneumatic system requires treatment of the ambient air to remove contaminants before it can be used to power any equipment. Therefore, the air preparation system—also called air source treatment components—is essential.

Among these air preparation components, there is a special combination group called FRL, that composed of several independent filtering, lubricating, and regulating elements, or sometimes all these elements are combined into one integrated FRL unit.

The air filter can effectively remove solid impurities and liquid contaminants from the air, providing the pneumatic system with clean, dry, and stable compressed air. This not only improves the reliability and precision of the equipment operation but also significantly extends the service life of pneumatic components and reduces maintenance costs. It plays an important role in ensuring the performance and longevity of the pneumatic system.

There are many types of compressed air filters, and their working principle is to capture, adsorb, or discharge moisture and particles. Proper cleaning and maintenance of air filters will help your pneumatic system achieve optimal performance and minimize energy consumption.

After installing pneumatic air filters, it is crucial to understand how to maintain and clean them. This will help optimize system performance and extend their service life. Once you are familiar with how pneumatic filters work, you will know when they need maintenance and cleaning.

The most important factor in maintaining any air filtration system component is regular inspection and cleaning. First, you should follow the manufacturer's instructions. If your filter does not come with specific cleaning instructions, follow these general steps:

◆ Turn off the compressor and allow it to cool down.

◆ Unscrew the top cover of the filter and remove it from the base.

◆ Visually inspect the top cover for any damage or issues.

◆ Remove and inspect the filter element — this is the focus of cleaning.

◆ Use low-pressure compressed air to blow off any contaminants on the filter element.

◆ If there is no wear or damage, gently reinstall the element into the base.

◆ Reattach the top cover.

◆ If possible, keep a maintenance and cleaning record sheet regularly.

You need a compressed air filter because normal ambient air is far from clean. Some of the most common contaminants include:

1)Pollen

2)Dust

3)Rust

4)Oil

5)Moisture

6)Tobacco smoke

7)Exhaust gases

9)Paint and solvent particles

10)Sanding residue

11)Cleaning and lubricant residues

12)Furnace debris

13)Aerosols

14)Pesticides

These tiny contaminants accumulate over time and eventually clog the filter, leading to compressor shutdown. You need an air treatment system with multiple filtration stages to isolate, capture, or remove these pollutants in order to obtain pure, clean compressed air.

If the filter is not cleaned regularly, it will place unnecessary strain on the compressor and reduce the overall air quality of the pneumatic system. The compressor will have to work harder, which may lead to premature wear of the compressor and other pneumatic components and increase energy costs.

The pneumatic air filter is designed for long-term use, but you should consider replacing it if you notice:

A significant increase in pressure differential between the inlet and outlet, or a decrease in compressed air flow;

The filter element becomes clogged much earlier than the normal service cycle;

Excessive oil-water mixture or high liquid level in the drain cup;

Water droplets, rust, or corrosion appearing on the filter housing;

Abnormal airflow noise or vibration during operation.

If any of these occur, you should replace the pneumatic air filter.

The best way to prevent internal contaminant buildup or filter blockage is through regular cleaning and timely replacement before serious problems occur. This is especially important if your professional reputation or product quality depends on the purity of compressed air or the performance of compressors.

In industries such as food and beverage processing or pharmaceutical manufacturing, regularly replacing filters is crucial to avoid costly failures or production delays.Routine maintenance and cleaning of air filters are key to achieving higher-quality compressed air. Running a pneumatic system with old or dirty filters increases the risk of contamination by rust, dust, pollen, and other particles.

Clean and well-maintained filters help remove these contaminants, improving the purity of compressed air. This makes your system safer, more energy-efficient, and provides a cleaner working environment for your employees.

Impact of Trapped Media in the Valve Cavity on Restart Performance of Pneumatic Ball Valves

Impact of Trapped Media in the Valve Cavity on Restart Performance of Pneumatic Ball Valves

Wear Path Analysis of Pneumatic Ball Valve Under Frequent Cycling Conditions

Wear Path Analysis of Pneumatic Ball Valve Under Frequent Cycling Conditions

Mini Push In Fittings: Aging Problems of Plastic Bodies in Humid Environments

Mini Push In Fittings: Aging Problems of Plastic Bodies in Humid Environments

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap