Feb 12, 2026

In pneumatic automation, the return speed of an actuator is often assumed to be determined by the cylinder or spring itself. Field experience shows that the exhaust capability of a 3 way solenoid valve plays a more decisive role. During the return stroke, compressed air inside the actuator must be released rapidly. If the exhaust path is restricted, the actuator may respond slowly even with a well-designed cylinder. This issue becomes critical in high-cycle equipment where milliseconds affect productivity.

When a 3/2 way solenoid valve switches state, the air trapped in the actuator flows out through the exhaust port. Because air is compressible, pressure drops quickly at first and then enters a slower release phase. A small exhaust port or a complex internal channel creates back pressure, delaying the return motion.

Many users install silencers to reduce noise on a 3-way pneumatic solenoid valve, but dense silencer elements often increase resistance and unintentionally slow the actuator.

| Item | Effect |

|---|---|

| Port size | Larger → faster exhaust |

| Channel shape | Straight → lower loss |

| Silencer density | Higher → more back pressure |

| Hose length | Longer → slower response |

| Actuator load | Heavier → longer return |

For a compact 3 way solenoid valve, space limitation usually means a smaller exhaust section. According to fluid dynamics, a 20% reduction in diameter can reduce effective exhaust capacity by nearly 40%. This explains why replacing one 3 way solenoid valves brand with another may noticeably change cycle time even under the same pressure.

Under light load, exhaust restriction may not be obvious. With higher mechanical resistance, the problem becomes evident.

Using a 3 way normally closed solenoid valve on a spring-return actuator, residual pressure competes with the spring force if exhaust is insufficient, leading to incomplete or slow return. Such symptoms are frequently mistaken for cylinder failure while the real cause lies in the valve.

Effective solutions focus on matching valve exhaust to actuator volume:

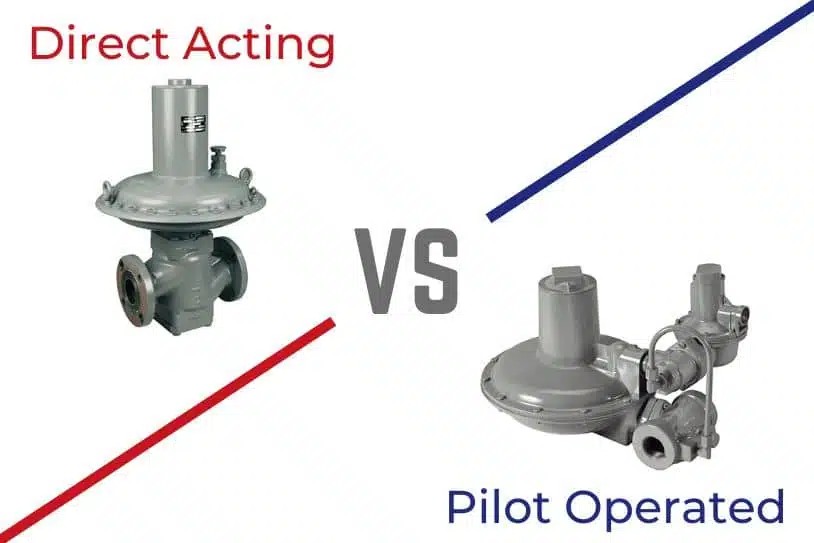

◆ Prefer pilot operated 3 way solenoid valve for large cylinders

◆ Avoid over-restrictive silencers on the exhaust port valve 3 way

◆ Shorten tubing and minimize bends

◆ Consider fast response 3 way solenoid valve for high-cycle systems

These measures often reduce return time by 20–35% without changing the actuator.

Whether selecting a 3 way valve for pneumatic cylinder or a valve for air actuators, the exhaust path should be evaluated as carefully as the inlet. When comparing industrial automation solenoid valves, engineers should review Cv value, internal channel design, and real exhaust capacity rather than only coil voltage or connector type such as DIN connector 3/2 solenoid valve.

Understanding this principle helps agents, equipment engineers, and end users build more stable and predictable pneumatic systems.

(FK9025)

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Coil Overheating on Continuous Duty of 2-Way Solenoid Valve

Influence of Coil Overheating on Continuous Duty of 2-Way Solenoid Valve

PVC Flexible Tubing vs PU Tubing: Cost Difference Analysis in Equipment Internal Routing

PVC Flexible Tubing vs PU Tubing: Cost Difference Analysis in Equipment Internal Routing

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

You May Interest In

Dec 06, 2025 Blog

How to check pneumatic solenoid valve?

Dec 04, 2025 Blog

How does a single solenoid valve work?

Dec 03, 2025 Blog

What is double acting solenoid valve?

Dec 02, 2025 Blog

How to clean a pneumatic solenoid valve?

Dec 01, 2025 Blog

How to Wire and Install a Pneumatic Solenoid Valve?

Nov 30, 2025 Blog

How to select pneumatic solenoid valve?

Nov 29, 2025 Blog

Operational Mechanism of Pneumatic Solenoid Valves

Nov 27, 2025 Blog

What is pilot operated solenoid valve?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap