Nov 27, 2025

In the world of industrial automation, valves play a vital role in regulating the flow of fluids, gases, and other media. Among the various types of valves, pilot-operated solenoid valves have gained significant attention in recent years. But what exactly are they, and how do they function?

In this article, we dive into the fundamentals of pilot-operated solenoid valves—examining their structure, working principles, and the advantages that make them a preferred choice in modern automation systems.

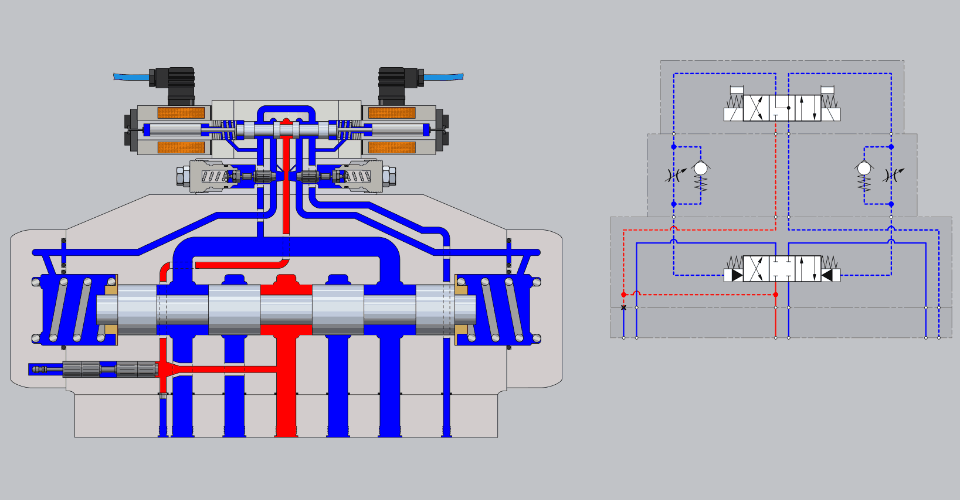

Pilot-operated solenoid valves are a type of solenoid valve that uses a small coil and system fluid pressure to assist in opening or closing the main valve. Due to their low current consumption, smooth operation, and minimal pressure loss, pilot-operated electromagnetic valve can control pipelines with larger diameters.

Unlike direct-acting valves, the pilot-operated solenoid valve uses the fluid pressure to drive the main valve, while the solenoid only controls a small pilot orifice. Therefore, it is suitable for high-pressure, high-flow systems, requires less electromagnetic force, but has a relatively slower response speed.They are widely used in various medium transport systems.

Greater Flow Capacity: One of their biggest advantages is their ability to handle larger flow rates and higher pressures.

Lower Energy Consumption: Environmental friendliness is also a significant advantage; compared to direct-acting valves, they require less electricity to operate.

Faster Response Time: Pneumatically operated pilot-operated solenoid valves can achieve faster opening and closing.

Long-Term Stability: The slow actuation of the main valve diaphragm/piston in pilot-operated valves effectively avoids water hammer, loud impact noise, and pipeline vibration.

High Reliability and Long Lifespan: Due to their simple structure, fewer critical components, and uniform pressure and temperature resistance, pneumatically operated pilot-operated solenoid valves often have a lifespan exceeding 1 million cycles.

Pilot-operated solenoid valves are driven by pressure differential. Their control process mainly includes the following three stages:

Solenoid pilot mechanism – Control chamber pressure

Control chamber – Controls main valve operation

Main valve – Large flow control

Working process

De-energized state (default state): The coil is de-energized, the pilot valve is closed, and the main valve is closed.

The control chamber obtains pressure from the inlet through the balance orifice. The diaphragm/piston is pressed against the main valve port by the pressure from above.

The main valve is tightly closed, and fluid cannot pass through.

Electrified state: The coil is energized, the pilot valve and the main valve open.

After energization, the pilot valve core rises, opening the pilot orifice. The control chamber is directly connected to the outlet, and the pressure is quickly released. The pressure in the control chamber drops, and the pressure in the lower chamber (inlet side) pushes up the diaphragm or piston of the main valve, causing the main valve to open wide, allowing a large flow rate.

Pilot-operated solenoid valves do not directly provide the driving force.The main valve's operation is achieved through the pressure difference of the fluid medium.

If the inlet pressure is insufficient, or the pressure difference between the inlet and outlet is too small, the following may occur:

❌ The diaphragm cannot be pushed up by the pressure → The main valve cannot open.

❌ The pressure in the upper chamber cannot decrease → The valve is sluggish or does not operate.

Agriculture and Horticulture: Pilot-operated solenoid valves can control water flow in different areas, opening and closing at set times, providing stable operation. They are very common in agricultural irrigation, orchard drip irrigation, and automatic greenhouse irrigation.

HVAC: Solenoid valves can be used for refrigerant piping switching and controlling cooling water/chilled water branches.

Building and Municipal Engineering: Automatically controlled pilot-operated solenoid valves can be used for building water supply control, automatic switching of landscape fountains, and underground pipe gallery water systems.

Fluid Process Control: Pilot-operated solenoid valves are ideal for switching and controlling large flow rates of liquids, such as in chemical pipelines, food-grade water systems, and beverage production lines.

Energy Industry: Due to their stable structure and high pressure resistance, pilot-operated valves can be used in harsh environments such as solar water heating systems, geothermal system switching, and auxiliary water control in hydroelectric power plants.

(9016)

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap