Nov 26, 2025

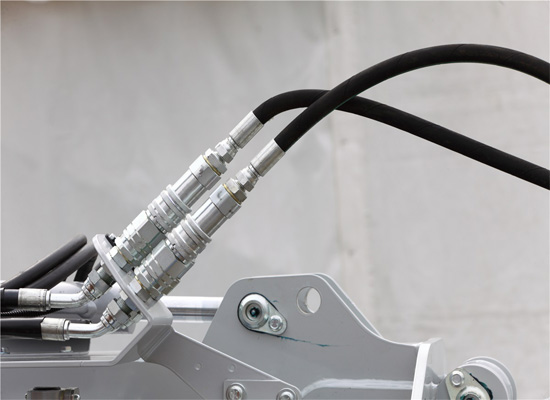

Hydraulic quick couplings allow for safe and reliable connection or disconnection of hydraulic lines or components within seconds. Before operation, ensure the system pressure is fully released to prevent oil spillage or accidents. Proper connection ensures smooth hydraulic fluid flow, reducing leakage and system losses.

When installing hydraulic quick couplings, select a model that matches the system pressure, flow rate, and piping specifications. Inspect the seals and end faces for cleanliness and undamaged surfaces, ensuring a good seal after tightening. Correct installation not only ensures coupling performance but also extends its service life.

Simple definition: A device that allows for the quick, tool-free connection and disconnection of hydraulic lines.

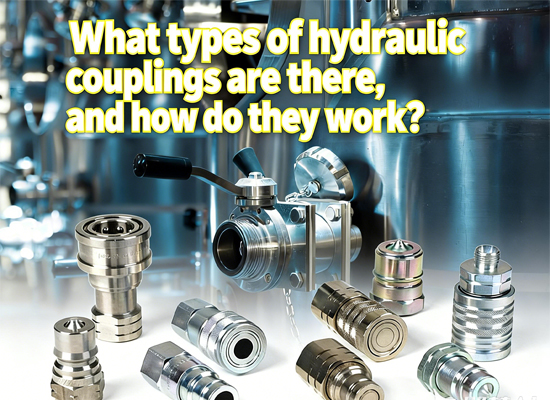

Hydraulic quick couplings come in various types, including ball-lock, flat-seal, insert, and threaded-lock. The appropriate type should be selected based on the pressure, flow rate, and type of the hydraulic system.

The coupling must be perfectly matched with the pipeline, equipment, and hydraulic components to maintain system compatibility and avoid leaks or pressure losses caused by incompatible specifications. Different equipment has different sealing and connection requirements.For example, flat-seal couplings are commonly used in excavator hydraulic breakers, while ball-lock couplings are typically used in agricultural machinery.

Before use, inspect the male and female connectors for damage, wear, or contamination. Ensure the seals are intact.

(1)Remove the dust caps from both the male and female connectors.

(2)Align the male connector directly with the female connector.

(3)Gently push until the male end face contacts the female connector.

(4)Apply steady force until you hear or feel a "click," indicating the locking mechanism is in place.

(5)Slightly pull back the connector to ensure it is fully locked and will not come loose.

Most importantly, the hydraulic system must be completely depressurized before disconnecting.Operate the unlocking mechanism according to the connector type.

(1)While keeping the unlocked mechanism in place, separate the male and female connectors.

(2)Immediately replace the dust caps on both the male and female connectors; this is the simplest and most important step in preventing contamination.

Regular maintenance of hydraulic joints helps prevent leaks, reduce malfunctions, and extend the system's lifespan.

Check for leaks regularly

If you notice oil seepage:

Replace the O-ring

Check whether the male or female coupler is deformed

Replace the entire coupler if necessary

Keep the couplers clean

Contaminants such as dirt, sand, and metal particles are harmful to hydraulic systems.

Always install the dust cap after use.

Avoid excessive pulling or twisting of hoses

Excessive force on the hose can damage the coupler's sealing surfaces.

Lubricate periodically

Apply a small amount of anti-rust lubricant to the locking balls and sleeve (avoid spraying into the hydraulic ports).

Replace aging couplers regularly

Especially when:

The couplers are frequently used in dirty or construction environments

The equipment experiences strong vibration

The couplers have been repaired multiple times

Hydraulic couplings should never be connected or disconnected while the system is under pressure to avoid oil spray and safety hazards. During use, mechanical pulling, excessive bending, or impact on hoses and couplings should be avoided to prevent damage. When not in use, couplings should be protected with dust caps to keep contaminants out and maintain sealing performance and hydraulic fluid cleanliness.

Regular lubrication and inspection are recommended. Common issues such as leakage, difficult connection, or restricted flow are often caused by wear, aging, contamination, or improper matching, and should be addressed promptly to ensure stable and reliable hydraulic system operation.

Safely depressurize the system, unscrew the old coupler, and install a new one using proper seals and torque.

Identify it by its thread type/size, physical shape, locking mechanism, and any brand/model numbers stamped on it.

Cut the hose cleanly, assemble the fitting onto the hose correctly, and then connect the quick coupler to the equipment after ensuring the system is depressurized.

(FK9016)

You May Interest In

Nov 25, 2025 Blog

How to replace hydraulic quick coupler?

Nov 23, 2025 Blog

How to identify hydraulic quick coupler?

Sep 12, 2025 Blog

Main components and advantages of hydraulic systems

Sep 01, 2025 Blog

A Guide to 6 Common Hydraulic Quick Coupler Problems

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap