Nov 23, 2025

Hydraulic quick couplings are specialized connection devices widely used in hydraulic components and hydraulic transmission systems. Through precise structural design and high-quality material manufacturing, these couplings allow for tool-free connection of hydraulic lines, effectively improving equipment maintenance efficiency.

During operation, hydraulic quick couplings rely on their internal hydraulic sealing structures (such as ball valves, flat seals, and conical seals) to ensure stable and leak-free fluid flow even under high pressure. Various types of hydraulic couplings are designed to withstand high pressure, including pulsating pressures, impact loads, and harsh environments common in hydraulic systems.

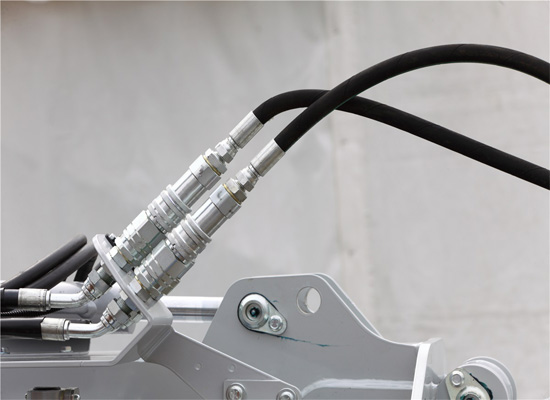

Hydraulic quick couplings typically consist of a male plug and a female socket. Their automatic locking upon insertion and easy release upon removal make them particularly suitable for scenarios requiring frequent accessory replacement, hydraulic hose maintenance, or modular equipment operation.

When identifying hydraulic quick couplers, you can examine factors such as structural shape, coupler type, size specifications, thread type, and brand markings.

◆ Quickly connect and disconnect hydraulic lines to improve equipment operating efficiency.

◆ Achieve efficient sealing and transmission of hydraulic media, ensuring stable system pressure and sufficient flow.

◆ Facilitate system maintenance and component replacement without disassembling the entire pipeline.

◆ Prevent hydraulic leaks, protecting equipment and operator safety.

◆ Suitable for various applications, such as construction machinery, agricultural machinery, and hydraulic industrial equipment.

Hydraulic couplings come in various materials and types to achieve different functions. Therefore, to find the right quick-connect hydraulic coupling for our system from among the many available options, we must have a certain understanding and knowledge of the various types of couplings.

Identifying hydraulic quick couplings ensures system compatibility, as different couplings vary in size, thread, construction type, sealing method, pressure rating, and flow capacity. It also improves safety, preventing oil spraying, system damage, or accidents caused by incorrect or worn couplings. Furthermore, it optimizes system performance, ensuring efficient hydraulic fluid transmission, reducing pressure loss, and maintaining a tight seal. Finally, it facilitates maintenance and replacement, making regular inspections, seal replacements, or system upgrades easier and more reliable.

Identifying a hydraulic quick coupling is essential in hydraulic equipment maintenance, system design, and daily operation. It plays a critical role in ensuring system compatibility, maintaining hydraulic sealing performance, withstanding high system pressure, and improving overall maintenance efficiency.

Quick couplings generally consist of a male and a female connector.The male connector is typically a protruding metal plug, while the female connector has a sleeve or locking mechanism.

Measure the diameter of the male and female connectors, insertion length, and the outer or inner diameter of the thread.

Common thread types: BSP, NPT, Metric.

Common sizes: 1/4", 3/8", 1/2", etc.

Common structures: Ball-lock, Flat-face, Push-to-Connect, Threaded-locking.Different structures determine the sealing method, flow capacity, and application scenarios.

The connector may be marked with a model number or standard code, such as ISO 7241-A, ISO 16028.

Different equipment uses different connector types, for example:

Excavator hydraulic breaker → Flat-face seal

Agricultural machinery → Ball-lock

Features: Uses ball locking mechanism for quick and reliable connection and disconnection.

Typical Applications:

Agricultural machinery (tractor hydraulic attachments)

Light to medium construction equipment

Portable hydraulic tools

Advantages: Suitable for low to medium pressure systems; ideal for frequent connect/disconnect operations.

Features: Flat sealing surfaces reduce oil leakage and cavitation.

Typical Applications:

Excavator hydraulic breakers

Construction machinery hydraulic lines

High-pressure hydraulic systems

Advantages: Minimizes fluid loss and prevents air ingress; ideal for high-pressure and frequent-use applications.

Features: Simply push to connect; no rotation or extra tools required.

Typical Applications:

Automated production line hydraulic components

Small hydraulic devices

Low-pressure portable equipment

Advantages: Quick and easy operation; suitable for low-pressure, fast-change scenarios.

Features: Secured by threaded connection, very robust.

Typical Applications:

High-pressure industrial hydraulic systems

Oil and mining hydraulic equipment

Long-term fixed hydraulic lines

Advantages: High pressure rating; ideal for high-pressure, stationary, or long-duration applications.

FOKCA Automation Co., Ltd. offers a wide range of hydraulic quick couplers to meet various industrial and hydraulic system needs. Our product line includes: Thread Locking, Flat Face, Push and Pull, Stainless Steel, Medium-Pressure, Ball Valves Type Hydraulic Quick Couplings, and also provides ISO 7241 A/B Quick Couplings.You can visit our website or contact us directly!

(FK9016)

You May Interest In

Nov 26, 2025 Blog

How to use hydraulic quick coupler?

Nov 25, 2025 Blog

How to replace hydraulic quick coupler?

Sep 01, 2025 Blog

A Guide to 6 Common Hydraulic Quick Coupler ProblemsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap