Nov 22, 2025

In industrial automation equipment, pneumatic cylinders are among the most common and essential actuators. Among all tuning tasks, adjusting cylinder speed is often a key factor that directly influences system performance and production efficiency.

If a cylinder moves too quickly, it may create impact at the end of its stroke, causing vibration, loosening of mechanical components, and even damage to grippers, fixtures, or conveyed materials. On the other hand, if the speed is too slow, it can delay the production cycle and reduce the throughput of the entire production line. Unstable speed control can also affect repeatability and positioning accuracy, leading to variations in product quality or even defective parts.

This article provides a systematic overview of the factors that affect pneumatic cylinder speed and the methods used to adjust it, helping you make better decisions when tuning pneumatic systems in real-world applications.

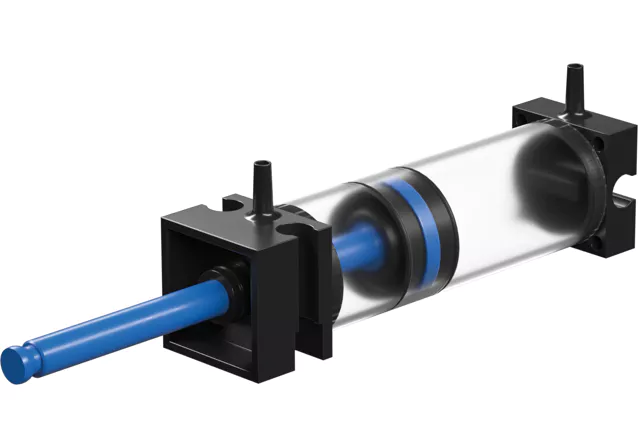

To understand how pneumatic cylinder speed is adjusted, you must first grasp the fundamental principle behind cylinder motion: the speed of a cylinder is essentially determined by the airflow. In other words, the more compressed air the cylinder can intake or exhaust per unit time, the faster the piston will move; when the airflow is restricted, the piston speed naturally decreases.

From a theoretical perspective, cylinder movement is the result of a dynamic balance between air filling and air exhausting—a process influenced by both the inlet and outlet of the cylinder.

Air enters the cylinder chamber → pushes the piston forward

Air exits from the opposite side → allows space for the piston to move

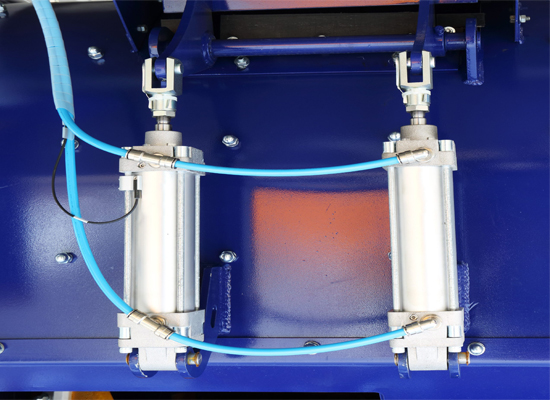

Install a one-way throttle valve on the cylinder’s exhaust side, also known as exhaust throttling, to control speed by regulating the amount of air discharged.

Advantages:

Stable speed with minimal vibration

The most commonly used speed control method

Adjustment:

Turn clockwise → less exhaust → cylinder moves slower

Turn counterclockwise → more exhaust → cylinder moves faster

Throttle on the inlet side to control the amount of air entering the cylinder.

Advantage: simple structure

Disadvantage: sensitive to load changes, speed less stable.

A speed control valve combines a check valve and a throttle orifice, allowing the air to be throttled in one direction (slowing movement) while flowing freely in the opposite direction, thereby controlling the cylinder's inlet or exhaust speed.

A proportional valve continuously adjusts supply pressure or flow, allowing smooth and precise cylinder speed control, and can be remotely controlled by a PLC.

Increasing pressure → speed may increase

Decreasing pressure → speed decreases

However, this method also affects the cylinder's output force and is usually not used as the primary method for speed control.

It accelerates cylinder motion by shortening the exhaust path and allowing rapid air release.

By reducing the supply pressure, it decreases cylinder force and thus reduces cylinder speed or weakens its motion.

These components influence cylinder speed by changing airflow resistance and the system’s flow capacity.

A larger orifice provides higher airflow and faster response, allowing the cylinder to operate at higher speeds.

The speed control valve may be too small, there may be air leakage, the tubing diameter might be too large, or a quick exhaust valve is affecting exhaust flow; check whether you're using exhaust throttling and confirm the valve is actually restricting airflow.

It’s often caused by load changes, poor lubrication, unstable line pressure, or inlet throttling; switch to exhaust throttling and check supply stability.

Usually due to high friction at low speed, excessive throttling, insufficient lubrication, or worn seals; slightly open the throttle and inspect the cylinder and valve condition.

The valve may be installed in the wrong direction (check valve bypassing), the throttle orifice may be blocked, or system flow may be too high for the valve to have an effect.

Because the exhaust is too fast and the motion becomes too aggressive; add cushioning on the cylinder, reduce air pressure, or avoid using a quick exhaust valve where smooth motion is required.

Our company mainly provides a variety of pneumatic products, including air operated cylinders product, various compatible cylinder components, pneumatic tubes, and pneumatic fittings. With decades of experience in overseas export and manufacturing, we welcome your inquiries.

You May Interest In

Nov 21, 2025 Blog

How does a pneumatic air cylinder work?

Nov 20, 2025 Blog

How mush air does a pneumatic cylinder use?

Nov 15, 2025 Blog

How long do pneumatic cylinders last?

Nov 14, 2025 Blog

How fast can a pneumatic cylinder move?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap