Nov 14, 2025

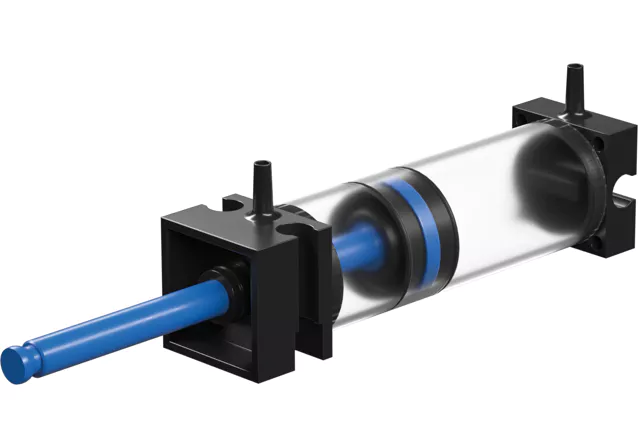

The speed of a pneumatic cylinder is a critical consideration in system design. It is not an isolated parameter but directly affects the overall performance, stability, service life, and safety of the system.

The cylinder speed can impact various aspects of system performance: while maximizing speed to reduce cycle time is essential for efficiency, it must be balanced with stability. When a cylinder operates at excessively high speeds and reaches the end of its stroke, the piston can violently impact the end covers, causing damage to both the front and rear ends of the cylinder. This accelerates wear on the buffer seals, leading to buffer failure. The impact force is also transmitted throughout the pneumatic circuit and mechanical structure, accelerating fatigue in all connected components. At high speeds, if a clamp fails or the load is not securely held, it may be ejected, potentially injuring operators or causing accidents.

Cylinder model: Ø32 × 200 mm stroke

Load weight: 3 kg

Supply air pressure: 0.6 MPa

Valve specification: Cv = 0.45 (standard 5/2 solenoid valve)

Target motion: Extension stroke from 0 → 200 mm

Stopwatch Method

This method measures the total time the cylinder piston rod takes to move from its starting position to the end position. The following are the three measurement results.

| serial number | Total travel time | Converted speed |

| One | 0.42 | 476 mm/s |

| Two | 0.40 | 500 mm/s |

| Three | 0.41 | 488 mm/s |

Average speed = (476 + 500 + 488) / 3 = 488 mm/s

Advantages of this calculation method: fast and simple.

Disadvantages of this calculation method: susceptible to human reaction, with an error of ±5~10%.

Sensor Measurement

The measurement actually measures the positional change of the piston inside the cylinder. Using a magnetic switch and PLC timing input, the measurement measures the positional change of the piston within the effective movement time of a stable speed ranging from 20mm to 180mm.

Distance: 160mm

PLC Timing: 0.325 s

160 mm ÷ 0.325 s = 492mm/s

Advantages of this method: Accurate, repeatable

Disadvantages of this method: Requires additional equipment

Flow Monitoring and Analysis

In cylinder speed measurement or air path optimization, flow monitoring and analysis typically detects changes in airflow in the cylinder's air supply line.

Average instantaneous flow rate during cylinder operation: 105 L/min

Theoretical speed estimation:

Based on a Ø32mm cylinder area (804 mm²) and stroke air requirement, the predicted speed is:

Theoretical speed ≈ 520 mm/s

Theoretical speed ≈ 520 mm/s

Choose Higher-Flow Valves

Most speed issues are caused by insufficient solenoid valve flow capacity.

Use Larger-Diameter Tubing and Fittings

Shorter tubing and larger diameters allow faster air supply and exhaust.

Optimize Exhaust Capability

Use quick exhaust valves to accelerate the release of compressed air.

Increase Supply Pressure Within Safe Limits

Increase acceleration within the allowable range of the cylinder structure.

Install Guide Rods

For loads that may rotate and apply lateral force or high torque, guide rods help prevent damage to the piston rod or cylinder body.

Improve Air Quality and Lubrication

Use air preparation units to enhance air quality, and apply lubricants in the actuator to reduce friction and improve efficiency.

| Brand / Model | Stroke Range | Typical Speed |

|---|---|---|

| SMC | 10–1000 mm | 50–1000 mm/s |

| Airtac | 10–800 mm | 100–800 mm/s |

| Festo | 10–1200 mm | 50–1200 mm/s |

Regardless of the brand, the operating speed of a cylinder is affected by the following factors:

System air pressure (higher pressure results in higher speed)

Load weight and friction

Pneumatic circuit design (pipe diameter, valve response speed, etc.)

Valve/throttle settings

The speed can be adjusted by regulating the throttle valve to control the air intake or exhaust flow, or by using a quick exhaust valve.

The air consumption depends on system pressure, stroke length, and the frequency of operation.

Industrial pneumatic cylinders typically have a lifespan of several million strokes, and their durability also depends on factors such as structural quality, seal material, usage frequency, and load conditions.

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Coil Overheating on Continuous Duty of 2-Way Solenoid Valve

Influence of Coil Overheating on Continuous Duty of 2-Way Solenoid Valve

PVC Flexible Tubing vs PU Tubing: Cost Difference Analysis in Equipment Internal Routing

PVC Flexible Tubing vs PU Tubing: Cost Difference Analysis in Equipment Internal Routing

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

You May Interest In

Nov 22, 2025 Blog

How to adjust pneumatic cylinder speed?

Nov 21, 2025 Blog

How does a pneumatic air cylinder work?

Nov 20, 2025 Blog

How mush air does a pneumatic cylinder use?

Nov 15, 2025 Blog

How long do pneumatic cylinders last?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap