Feb 07, 2026

A Vacuum generator is a compact device that creates negative pressure using compressed air rather than mechanical pumps. In modern automation systems, the pneumatic vacuum generator is widely used for material handling, pick-and-place operations, and robotic gripping because of its simple structure, fast response, and low maintenance requirements. Understanding how a vacuum generator works helps engineers select the right model for stable suction performance and efficient air consumption.

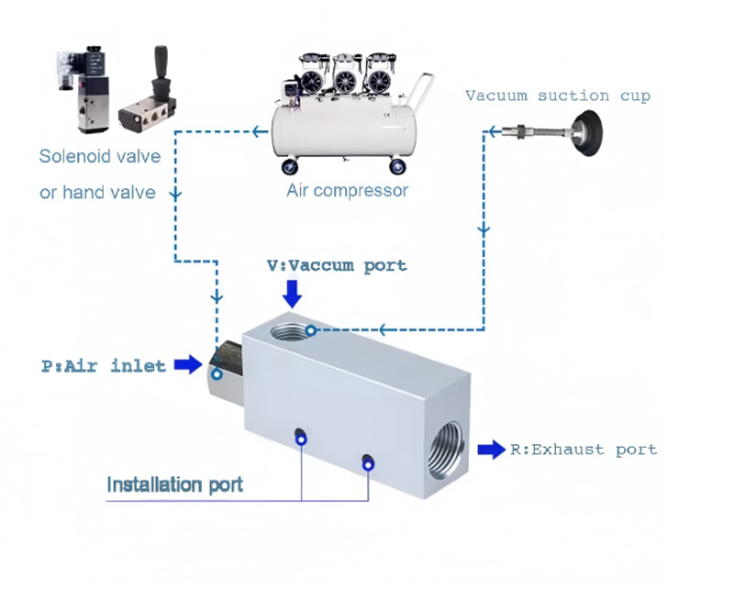

A pneumatic vacuum generator operates based on the Venturi principle. When compressed air passes through a narrow nozzle at high speed, the velocity increases while the pressure drops, creating a vacuum at the suction port. This vacuum can then be used to hold or transport objects through suction cups or vacuum lines.

Unlike mechanical vacuum pumps, vacuum generator pneumatic systems contain no rotating parts, making them suitable for high-frequency automation processes where reliability and fast cycle times are critical.

Inside a Vacuum generator, compressed air enters the nozzle section and accelerates through a converging channel. The pressure drop generated in the expansion chamber creates a suction effect that pulls air from the connected vacuum line.

Key operating steps:

1.Compressed air enters the generator inlet.

2.Air accelerates through the Venturi nozzle.

3.Low pressure is created in the suction port.

4.Air is discharged through the exhaust silencer.

Stable air supply pressure directly determines vacuum efficiency and response speed, so proper regulator settings are essential during system installation.

Compared with traditional vacuum pumps, pneumatic vacuum generators provide several operational advantages:

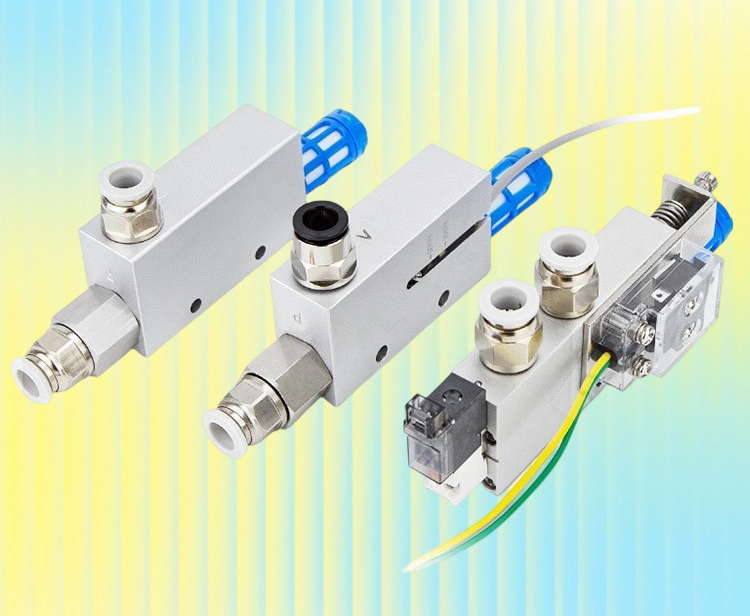

◆Compact structure, easy installation close to suction points

◆Fast vacuum response, suitable for high-cycle automation equipment

◆No electrical drive required, safe for wet or explosive environments

◆Low maintenance, minimal moving components

◆Flexible modular design, easy integration with vacuum filters and switches

These features make the smc pneumatic vacuum generator type design widely adopted across industrial automation sectors.

| Parameter | Pneumatic Vacuum Generator | Mechanical Vacuum Pump |

|---|---|---|

| Response time | Very fast | Moderate |

| Installation size | Compact | Larger |

| Maintenance level | Low | Medium |

| Energy source | Compressed air | Electric motor |

| Best application | High-cycle automation | Continuous vacuum supply |

For intermittent or distributed suction points, pneumatic solutions are often more efficient and economical.

The pneumatic vacuum generator is commonly used in automated production environments where rapid and repetitive suction is required:

◆Robotic pick-and-place systems

◆Packaging and labeling equipment

◆Sheet metal or glass handling

◆Electronics assembly lines

◆Plastic molding part transfer

When combined with vacuum suction cups and vacuum filters, the generator forms a complete decentralized vacuum handling system suitable for flexible automation layouts.

Related products: Vacuum suction cups, vacuum filters, and pneumatic solenoid valves are typically integrated into the same control circuit for stable system performance.

Choosing the correct Vacuum generator depends on system operating requirements. Engineers should evaluate:

◆Required vacuum level

◆Air consumption capacity

◆Object weight and surface condition

◆nstallation space limitations

◆Response time requirements

Proper sizing prevents excessive compressed-air usage while ensuring sufficient suction force, improving both operational efficiency and energy cost control.

The Vacuum generator pneumatic system offers a simple, durable, and highly responsive method for generating vacuum in industrial automation processes. Its compact design, fast reaction speed, and low maintenance requirements make it an ideal solution for distributed vacuum applications, particularly in robotic handling and packaging lines. Selecting the correct model based on vacuum demand and air supply conditions ensures stable long-term performance.

(FK9026)

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

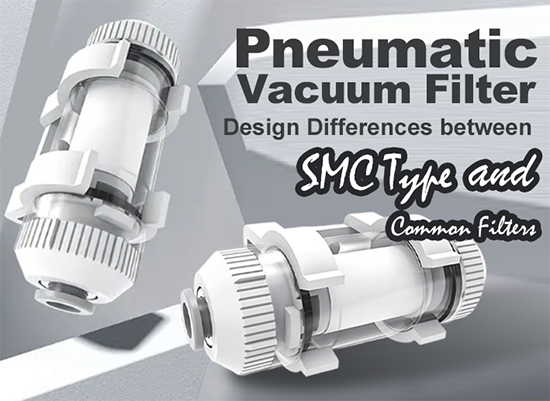

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

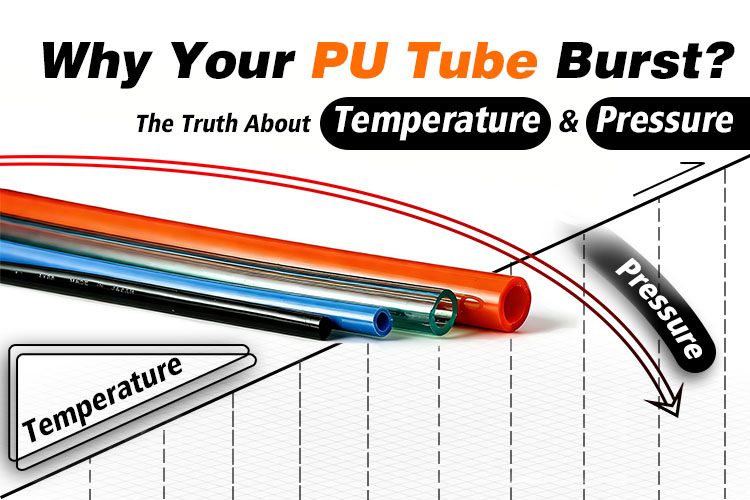

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap