Feb 05, 2026

A reliable Pneumatic Vacuum Filter is the gatekeeper of every vacuum gripping system. In automated assembly and packaging lines, tiny particles or oil mist can directly reduce suction force and damage valves. Many users compare SMC style products with ordinary versions and wonder why the price and performance vary so much. The key lies in sealing structure, filtration stability, and service life of the vacuum filter rather than simple appearance.

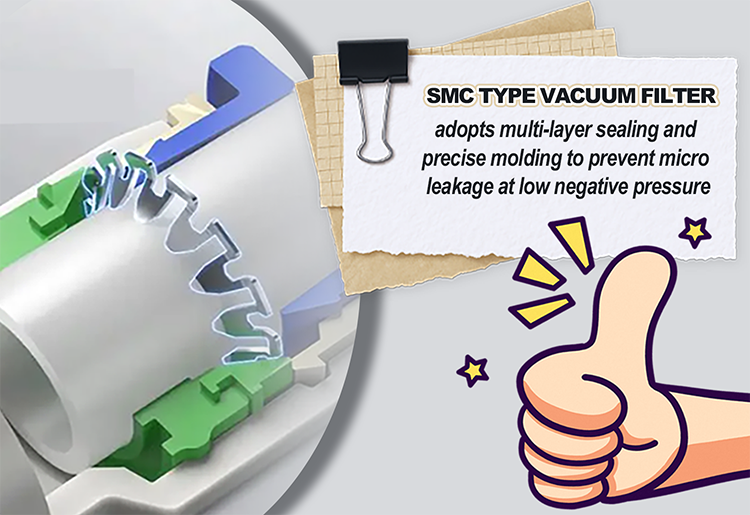

The first difference appears in the sealing design. SMC type Vacuum System Filter usually adopts multi-layer sealing and precise molding to prevent micro leakage at low negative pressure. Common filters often rely on single O-ring or rough thread sealing, which may work in clean labs but becomes unstable on vibrating machines. Better sealing means more stable suction force and protects expensive vacuum generators from contamination.

Inside the element, material selection plays a decisive role. High-grade Pneumatic Vacuum Filter uses uniform fiber or sintered media to keep pressure drop constant even after long hours. Ordinary products may show good initial flow, but pores deform quickly when exposed to oil mist. As resistance rises, the robot gripper reacts slowly. Engineers value Vacuum Suction Filter that maintains the same response from the first month to the last.

Another gap lies in replaceability. SMC style units are designed for quick cartridge change without removing the body from the pipeline. Many low-cost vacuum filter models require full replacement once clogged, increasing downtime. In factories with thousands of suction cups, this difference directly affects annual maintenance budget. Longer life is not only about material, but about service concept.

| Aspect | SMC style | Common type |

|---|---|---|

| Sealing | Multi-layer precision | Single ring |

| Media quality | Uniform, stable | Easy deformation |

| Pressure drop | Low and constant | Rising quickly |

| Maintenance | Replaceable element | Whole unit change |

| Vibration resistance | Strong | Limited |

For equipment engineers, the choice of Vacuum System Filter is linked to machine efficiency. Unstable filtration allows dust to enter ejectors and valves, causing sticking and slower cycle time. Packaging and electronics industries require repeatable suction to avoid product drop. Distributors who understand this logic can recommend the correct Pneumatic Vacuum Filter instead of competing only on price.

When selecting a Vacuum Suction Filter, consider working environment and air source quality. Oily workshops need metal housing and high-density media, while clean rooms may focus on ultra-low pressure drop. Thread size should match the generator but capacity must be slightly larger than actual flow. Providing these details to customers builds confidence and reduces after-sales issues.

A filter is a small component, yet it decides whether a vacuum system runs smoothly for years or fails repeatedly. Understanding the design differences between SMC style and common products helps users invest wisely and ensures that every Pneumatic Vacuum Filter delivers stable suction and long-term value.

(FK9026)

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

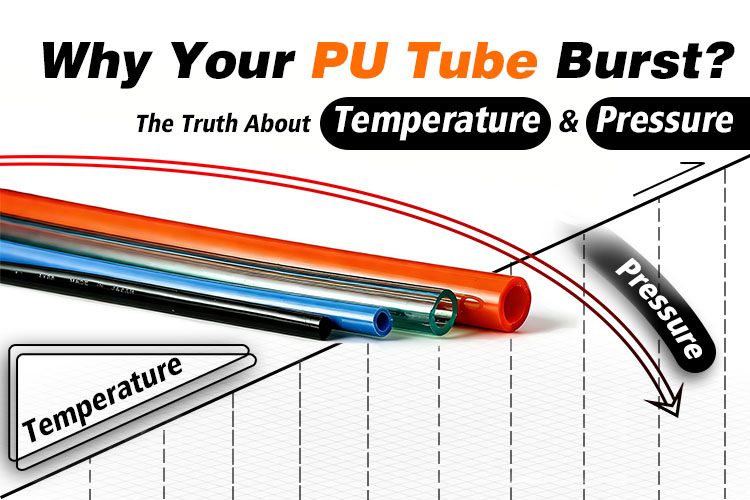

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap