Jun 09, 2025

Modern industries such as automotive manufacturing, electronics assembly, food packaging, and machining heavily rely on pneumatic cylinder to achieve automation, enhance production efficiency, and improve product quality.

A pneumatic cylinder is an air operated actuator that converts the energy of compressed air into mechanical motion — either linear or rotary. Pneumatic actuator is a core component in industrial automation systems.

But air actuator also come in different types depending on the industry,A pneumatic cylinder with a stainless steel piston rod can perform pushing, pulling, or ejection actions; a rodless cylinder moves a load through a slider or magnetic coupling mechanism; a rotary cylinder can output rotational motion.They each have different characteristics and applications. Next, let's look at other cylinder actuator types.

Regardless of cylinder type, pneumatic actuators offer several important advantages:

◆ Powerful Drive Force: The most prominent feature of pneumatic actuators is their ability to frequently and reliably handle pushing, pulling, clamping, positioning, lifting, and ejection operations.

◆ Compact Installation: Compact cylinders are typically equipped with high-strength aluminum alloy bodies, achieving a minimized footprint while delivering high-frequency, highly efficient actuation cycles.

◆ Fast Response & Precise Control: The low density of air allows it to flow quickly through the piping, rapidly transmitting energy to actuate the actuator.

◆ Low Cost & Environmentally Friendly: Uses clean compressed air resource, No need to worry about media leakage and pollution.

◆ Adaptability to Harsh Environments: Operates reliably in high-temperature, humid, or dusty environments types.

Pneumatic cylinders are mainly classified into single-acting and double-acting types.In addition, based on brand, structure, and function, they can also be categorized in the following ways:

The ISO 6431 cylinder is a commonly used pneumatic actuator standard type with standardized dimensions and specifications.

Features:

Standardized dimensions and port sizes

Typically cylindrical shape with a variety of stroke lengths and bore diameters

Equipped with seals and dust rings for airtight performance and durability

Functions:

Provides reliable linear reciprocating motion

Standardized design for easy installation and maintenance

Industries:

Machinery manufacturing

Automated assembly lines

Packaging equipment

The Pneumatic cylinder airtac is a cost-effective pneumatic actuator type choice.

Features:

Stable quality and cost-effective

Available in ISO standard, compact, mini, and other formats

Uses premium sealing components for long life

Functions:

Suitable for pneumatic actuation in a wide range of automation systems

Industries:

Automotive production

Electronics assembly

Food packaging

A small pneumatic cylinder is a compact type of cylinder actuator that requires precise control.

Structural Features:

Compact and lightweight

Simple design with short stroke lengths

Functions:

Ideal for light-duty operations such as positioning, clamping, and pushing

Industries:

Electronics manufacturing

Medical devices

Laboratory automation

Compact cylinder is kind of air actuator type that used in aspace-saving industries and application.

Structural Features:

Short and rigid body with a high force-to-size ratio

Suitable for medium loads in limited spaces

Functions:

Provides powerful actuation in space-constrained environments

Industries:

Machinery and equipment manufacturing

Automation equipment

Robotics applications

A double-rod cylinder is a type of cylinder designed to prevent rotation and ensure smooth operation.

Structural Features:

Dual piston rods ensure stable and precise motion without deflection

High rigidity prevents damage from lateral forces

Functions:

Delivers precise linear motion and guided support

Industries:

Precision assembly

Machining

Packaging machinery

SMC cylinders are a high-industry-standard brand of cylinders, encompassing various types including standard, compact, rod, and rodless cylinders.

Structural Features:

High-quality construction and comprehensive model selection

Available in standard, compact, mini, and other series

Functions:

Stable performance in various pneumatic control systems

Industries:

Automated production lines

Electronics manufacturing

Food processing machinery

A type of cylinder without a piston rod, which drives an external slider through a mechanical or magnetic mechanism and features a long stroke.

Structural Features:

No external piston rod; power is transmitted via magnetic or mechanical coupling

Space-saving design with long stroke capabilities

Functions:

Enables long-distance linear motion while saving space

Industries:

Automated assembly

Printing machinery

Logistics and material handling

A rotary cylinder is an actuator type that does not perform linear reciprocating motion, but outputs rotational movement to drive a load.

Structural Features:

Air-powered rotational actuator rather than linear motion

Available in piston-type or gear-type structures

Functions:

Provides angular motion for gripping, turning, indexing, etc.

Industries:

Automation systems

Robotic arms

Packaging and assembly equipment

Other types of cylinder actuators include long-stroke cylinders, stopper cylinders, and various customized designs.

Structural Features:

Equipped with high-strength guide rods or rails to absorb impact and prevent deflection under eccentric loads

Integrated cushioning and mechanical locking mechanisms

Supports various mounting methods

Functions:

Stops or locks moving parts in automated systems

Withstands high-impact environments

Industries:

Conveyor automation

Sorting systems

Automotive assembly

Although there are various types of cylinders, as relatively simple pneumatic actuators, their basic structural components are relatively simple, easy to maintain, and highly replaceable.

Cylinder Barrel

Piston

Piston Rod

Front and End Caps

Seals and O-Rings

Cushioning Mechanism

Mounting Accessories are essential for securing the cylinder in place and adapting it to various installation environments. Common types include:

Front/Rear Flanges

Foot Mounts

Clevis Mounts / Trunnion Mounts

Threaded Rod Ends / Rod Eye Bearings / Ball Joints

Used with cylinders that have magnetically-equipped pistons, enabling non-contact position sensing.

Purpose:

Detect piston position during stroke

Provide electrical feedback to the control system

Enhance automation accuracy and safety

Includes components like clevises, rod eyes, and spherical joints, designed to connect the piston rod to the external load.

Purpose:

Accommodate misalignment or angular motion

Allow secure and flexible coupling with the load

Reduce stress on piston rod and cylinder body

Installed on the air inlet or exhaust ports of the cylinder to regulate air flow.

Purpose:

Precisely control piston speed and stroke timing

Optimize movement smoothness

Improve process consistency and reduce wear

Often used in combination as an FRL unit, these components are essential for maintaining clean, dry, and properly lubricated air supply.

Purpose:

Filter out dust, water, and oil particles

Regulate air pressure to optimal levels

Lubricate internal cylinder components

Extend the service life and ensure reliable performance

FOKCA is the name of our pneumatic products manufacturing company,we delight in imparting extremely provide cylinders and related accessories designed for max efficiency and durability. But we do not just offer products — we offer reliable, long-term performance solutions.

Multiple types of cylinders meet different application needs. If you also have customized requirements, our technical team can also tailor solutions specifically for you. No matter what industry you belong to, such as industrial manufacturing, automation, DIY, you can directly contact us if you want pneumatic cylinder and accessories.

Pneumatic air cylinders, with their simple structure, quick response, and ease of maintenance, play an irreplaceable role in automation equipment. By selecting the appropriate pneumatic air actuators type and configuring the right accessories, equipment performance and production efficiency can be significantly improved. As actuating components, air cylinders—working in coordination with their accessories—form one of the fundamental power systems in modern intelligent manufacturing.Browse our cylinder actuator detail information:www.fescolo.com.

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

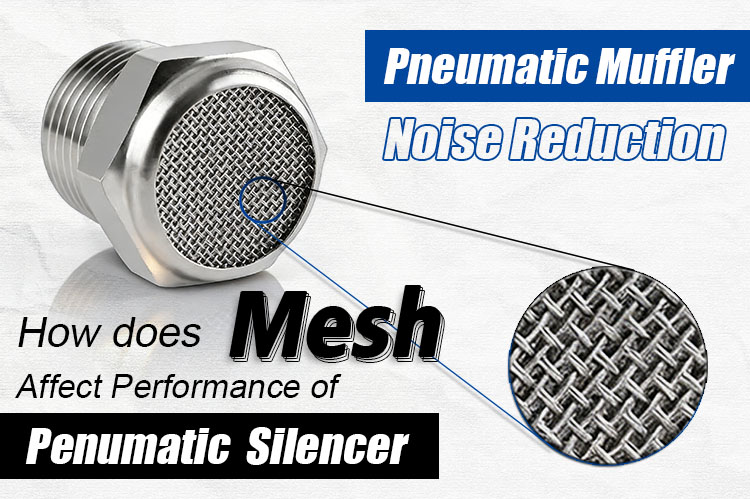

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Nov 12, 2025 Blog

What is a single acting cylinder?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap