Jan 29, 2026

In pneumatic systems, hose material is rarely an afterthought. A mismatched Rubber Hose or Polyurethane Tubing can shorten service life, increase leakage risk, or complicate installation on the production floor. For distributors, engineers, and purchasing teams, understanding how rubber, PU, and nylon tubes behave under pressure and movement helps avoid costly rework while improving system reliability.

At a material level, rubber air hose, PU hose, and nylon tube serve the same purpose—transporting compressed air—but they behave very differently in real applications. Rubber hose relies on elastomer flexibility, PU tubing balances elasticity with strength, while nylon tube emphasizes rigidity and pressure resistance. The right choice depends less on price and more on motion, pressure, and environment.

A rubber air hose is often selected where continuous movement or vibration exists. Rubber absorbs mechanical shock naturally, making it suitable for tool connections, mobile equipment, and manual workstations. Its thicker wall structure also offers good abrasion resistance in harsh industrial environments.

However, rubber hoses are heavier and typically have a larger bending radius. In compact automation layouts, routing rubber hose can become a space constraint.

Rubber is also less suitable for cleanroom or food-grade systems due to material additives.

Key advantage: excellent flexibility and vibration damping

Typical use: pneumatic tools, heavy-duty industrial equipment

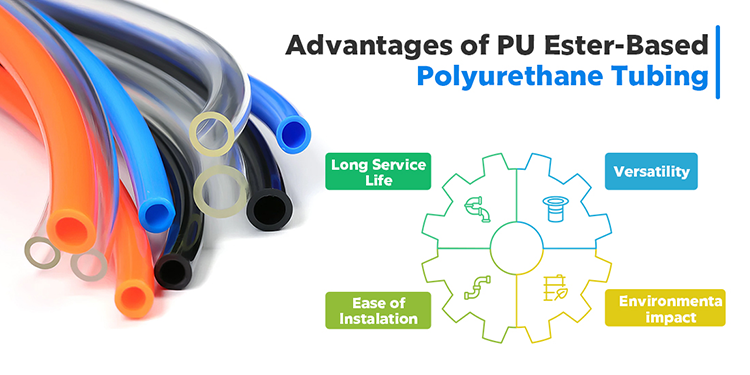

Polyurethane Tubing has become the default choice in modern pneumatic automation. Compared with rubber hose, PU hose is lighter, easier to route, and maintains flexibility even at smaller diameters. This makes it ideal for robotic arms, pick-and-place systems, and compact manifolds.

PU tubing also provides good resistance to oils and grease, which is why many equipment builders standardize on it.

PU hose offers the best balance between flexibility, durability, and cost, especially in OEM equipment.

In high-speed automation, reduced tubing weight directly improves actuator response.

When pressure consistency matters more than flexibility, nylon tube is the preferred option. Nylon tubing has high tensile strength, low expansion under pressure, and excellent chemical resistance. These properties make it suitable for fixed pneumatic lines, control circuits, and applications requiring stable airflow.

The trade-off is stiffness. Nylon tube requires careful installation and larger bending radii. It is not designed for constant movement, but performs exceptionally well in static or semi-static systems.

| Property | Rubber Hose | PU Hose | Nylon Tube |

|---|---|---|---|

| Flexibility | Very high | High | Low |

| Weight | Heavy | Light | Medium |

| Pressure Stability | Medium | Medium | High |

| Abrasion Resistance | High | Medium | Medium |

| Typical Applications | Tools, mobile lines | Automation, robotics | Fixed air lines |

Data based on industry material performance benchmarks.

For distributors and equipment engineers, selection should follow application behavior rather than habit.

Use rubber hose where movement is frequent, PU hose where routing and response time matter, and nylon tube where pressure stability is critical.

In many automation projects, a single machine may use all three materials across different zones.

Material choice directly affects maintenance cycles, installation time, and overall system performance. There is no universal “best” pneumatic hose—only the best match for the job. Understanding how Rubber Hose, Polyurethane Tubing, and nylon tube differ allows purchasing teams and engineers to make decisions that reduce downtime and improve system efficiency.

(FK9026)

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

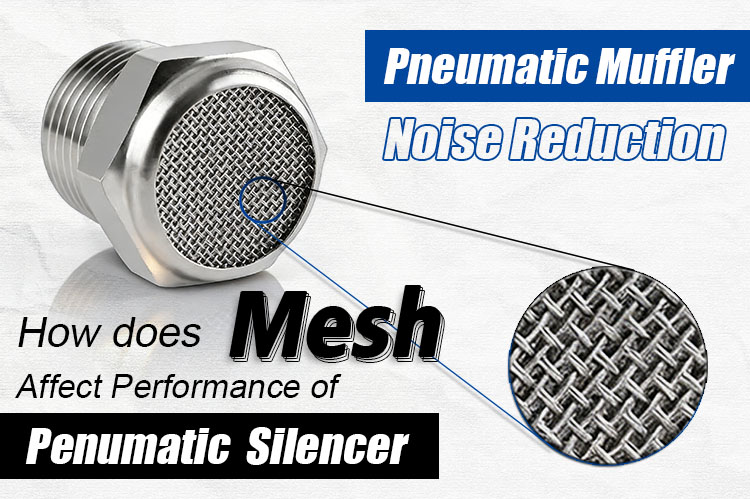

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap