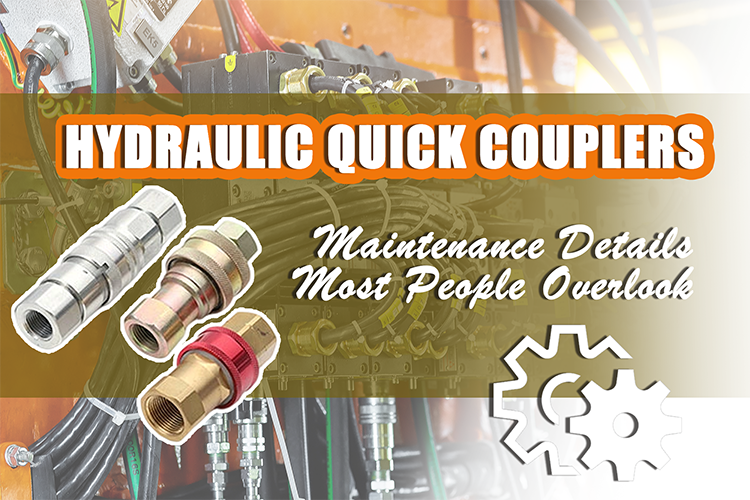

In daily operation, Hydraulic Quick Couplers are often treated as simple connection parts—plug in, disconnect, and move on. Yet many leakage issues, pressure drops, or premature failures are not caused by poor design, but by small maintenance details that are easily ignored. For anyone working with hydraulic components, understanding these overlooked points can significantly extend service life and system reliability.

Cleanliness Before Connection Is More Critical Than It Looks

During maintenance, connectors are frequently left exposed to dust, metal chips, or oil residue. Even small contaminants can be carried directly into the hydraulic circuit during reconnection. Contamination remains one of the primary causes of seal damage and valve sticking in hydraulic systems.

Wiping both the male and female ends before every connection is a basic habit, yet often skipped under time pressure. In high-pressure systems, a single grain of debris can compromise sealing surfaces. Clean couplers help protect downstream valves, pumps, and actuators.

Lubrication: Enough, but Not Too Much

Another commonly overlooked detail is lubrication. Seals inside high-quality hydraulic couplings are designed to operate with system oil, not excess external grease. Over-lubrication may attract dust and accelerate wear rather than prevent it.

A light film of compatible hydraulic oil on the sealing surface is usually sufficient. Using incorrect lubricants can cause seal swelling or chemical degradation, especially in systems using specialized fluids. This small detail often explains why couplers fail earlier than expected.

Connection Direction and Alignment Matter More Than Force

It is not uncommon to see operators force a coupler into position when alignment feels “almost right.” Misalignment during connection places uneven stress on locking balls and seals. Over time, this leads to leakage or incomplete locking.

Proper axial alignment reduces mechanical wear and improves sealing consistency. In angled or hard-to-reach installations, guiding brackets or swivel mounts can significantly reduce connection errors. Force should never replace correct positioning.

Pressure Residuals: The Hidden Enemy During Disconnection

Residual pressure trapped inside lines is a frequent source of damage. Attempting to disconnect Hydraulic Quick Couplers under pressure can scar sealing surfaces or deform internal components.

Many maintenance teams focus on pressure ratings but overlook depressurization procedures. Releasing residual pressure before disconnection protects both the coupler and the operator. This is especially important in mobile equipment or systems exposed to temperature fluctuations.

Seal Wear Is Not Always Visible from the Outside

External inspection often fails to reveal internal seal wear. Couplers may appear intact while micro-leakage develops internally. Over time, this reduces system efficiency and increases oil consumption.

| Maintenance Check | Why It Matters |

|---|---|

| Visual cleaning | Prevents contamination |

| Seal lubrication | Reduces friction |

| Alignment check | Avoids mechanical damage |

| Pressure release | Protects sealing surfaces |

| Periodic replacement | Prevents unexpected leaks |

Based on common hydraulic maintenance practices.

Preventive replacement of seals is often more cost-effective than reactive repairs.

Small Maintenance Habits Define Long-Term Reliability

For distributors, engineers, and plant managers, the message is clear: most quick coupler failures start with overlooked maintenance details, not product defects. Clean handling, correct lubrication, proper alignment, and pressure management all contribute to consistent performance.

In systems where uptime matters, choosing high-quality hydraulic couplings and maintaining them correctly is part of a broader reliability strategy—not just a component decision. When these details are treated as standard practice, hydraulic systems remain stable, efficient, and predictable throughout their service life.

(FK9026)