Apr 18, 2025

Angle seat valve,It is a complete integrated unit of "valve body + actuator", which can also be referred to as a full valve with an integrated pneumatic piston actuator. Without requiring external driving mechanisms, the pneumatic angle seat valve can achieve automated, rapid, and long-distance pneumatic control.The overall structure adopts a "Y" shape,which lifted valve core from the valve seat by the linear motion of the actuator piston to achieve the opening and closing. Usually, unique angle design commonly 90 degrees effectively reduces fluid resistance, providing higher flow velocity and faster response speed.

Angle seat valve due to the operation of pneumatic piston features tight closing performance, high circulation rate, and extremely long service life. It is widely used in fluid control systems that require high pressure, high temperature, and fast switching, and is very suitable for industrial automation media such as gas, steam, and water.

A pneumatic actuator is a means for achieving automated control of an angle seat valve. It not only enables faster opening and closing of the valve but can also be integrated with PLCs or DCS for remote control, enhancing equipment protection and personnel safety in emergency situations.Next, I will mainly introduce the working principle, advantages, types and applications of pneumatic angle seat valve.

Initial State

We all know that mostly valve with the cooperation of control system or actuator has normally open and normally closed are two common working states of valves. In both Normally Open (NO) and Normally Closed (NC) angle seat valves, the spring inside the actuator is the primary component that controls the piston, which in turn drives the valve plug to maintain either the open or closed state.If compressed air is introduced, its force acts against the spring force. If the thrust generated by the air pressure exceeds the force of the spring, it overcomes it, moving the piston and consequently changing the state of the valve.

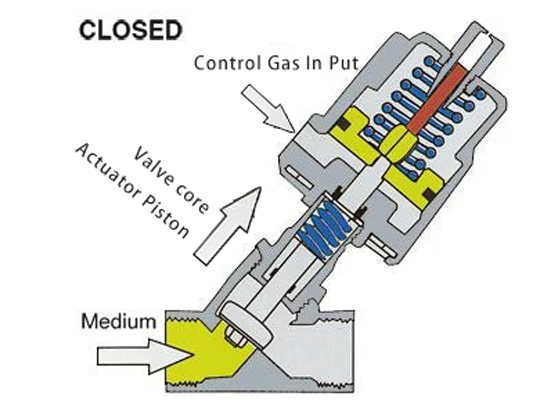

Before we know how does an angle seat valve work,we need understand the structural composition and working principle of the pneumatic angle seat valve firstly.

Valve Body: The main body of the angle seat piston valve is generally made of stainless steel, brass, or other high-pressure and corrosion-resistant materials, providing support for the internal working components.

Actuator: The pneumatic actuator component mainly drives the stem and the plug of the angle seat valve to perform the opening and closing motion.Its structure includes components such as the cylinder, piston, piston rod, and spring.

Valve stem:This is structural components of valves which is located inside the valve body and mainly connects the piston rod with the valve plug, serving to transmit both tensile and compressive forces.

Valve core and seat:The valve core is a key component for controlling the flow of the medium, and the seat valve is the sealing surface when the valve core is closed. Under the combined action of the valve plug and valve seat, the flow diameter (bore size) of the angle seat valve is influenced and controlled.

The operation of a pneumatic angle seat valve begins with a change from its normally open or normally closed state. This means that the angle seat valve first remains in an open or closed state under the action of its spring. Then, when the thrust of the supplied compressed air exceeds the spring force, it drives the piston to move, which in turn opens or closes the valve by actuating the valve plug. The following example illustrates this process using the normally closed state.

◆ In the initial state, the spring presses the valve plug tightly against the valve seat, keeping the flow passage closed.

◆ When the pneumatic actuator starts to operate, its piston rod moves and drives the angle seat valve stem, lifting the valve plug.

◆ After the air supply stops, the spring pulls the valve plug back to its original position, pressing it firmly against the valve seat and closing the fluid passage.

Pneumatic angle seat valve with Normally open state work in the opposite way.

Note that for an angle seat valve, a larger angle is not always better. If the turning angle is too large, vortices may form, causing energy loss of the medium. By adopting a 90° non-right-angle flow path design, the pneumatic angle seat valve ensures reliable sealing while significantly reducing flow resistance.

Pneumatic angle seat valve is a ideal for applications where high flow, fast response, and reliable sealing are required.Here are its common industry uses:

◆ HVAC Systems

◆ Chemical Processing

◆ Food and Beverage

◆ Automated Machinery

◆ Water Treatment Plants

Browse our article, and you might gain more insights into the application scenarios of pneumatically operated angle seat valves.

The common classification standards for angle seat valves include drive mode, material, function, connection type, and application conditions. In the following, we will focus on analyzing the types of pneumatic angle seat valves from the perspectives of characteristics, caliber, material, and brand.

◆ Standard Angle Seat Valve: Suitable for most industrial applications that require medium pressure and steam control.Like SMC,Festo,Airtac standards and so on.

◆ High-Pressure Angle Seat Valve: These are designed to handle high-pressure systems and are often used in oil & gas, and chemical industries.

◆Valve Orifice:The diameter of the air operated angle seat valve is different, for example, the PV100 series has a smaller diameter, while the PV500 series has a larger diameter.The larger the orifice, the more suitable it is for working conditions with higher flow rates.

◆ Stainless Steel Angle Seat Valve: Known for their corrosion resistance, these are ideal for environments where hygiene and durability are critical, such as the food and beverage industry.

◆ SMC Angle Seat Valve: SMC is widely used in pneumatic applications due to their high precision and reliability in controlling air flow.

Angle seat pneumatic valves are highly regarded for their efficient transmission of fluid media and reliable performance in a variety of fluid control applications. Let's discuss their other advantages:

◆ High Flow Rate

◆ Durability

◆ Space-Saving Design

◆ Smooth Operation

◆ Low Maintenance Cost

Pneumatic Actuation: With fast response and suitable for frequent operation industries but it requires an external air supply,Integration with a PLC and sensors is required to enable remote operation.

Electric Actuation: Actuating by electric actuator to control valve opening and closing, allowing remote operation but the opening and closing speed is slower than pneumatic actuator.

Manual Operation: The valve stem is operated by manually turning a handle or handwheel. This design is simple and low-cost, but it requires constant human involvement.

◆ Poor Sealing of the Valve Seat

◆ Valve Jamming or Failure to Actuate

◆ External Leakage

◆ Slow Response and Performance Degradation

◆ Abnormal Vibration and Noise

The performance and application of a angle seat valve largely depends on its valve body material and sealing material. When making a choice, it should be based on specific needs.

Stainless Steel: Corrosion-resistant, high-temperature tolerant, and high strength. Suitable for chemical processing, food and pharmaceutical industries, steam, and corrosive fluids.

Brass: Cost-effective and suitable for neutral media. Commonly used for compressed air, cooling water, and small-scale systems.

Plastic: Resistant to certain chemicals and lightweight. Ideal for low-temperature, low-pressure, and non-metallic environments.

PTFE: High temperature and corrosion resistance with low friction. Suitable for strong acids, alkalis, and high-temperature media.

NBR: Oil-resistant with good elasticity. Ideal for compressed air and hydraulic oil.

EPDM: Resistant to hot water and steam. Suitable for drinking water and low-concentration chemicals.

Fokca is a professional pneumatic actuated angle seat valve manufacturer of startup equipment based in Ningbo, specializing in a wide range of pneumatic valves, including Angle Seat Valves, Globe Control Valves, Solenoid Valves, and other valve products. Additionally, we offer Pneumatic Hoses & Connectors, Hydraulic Components, and other types of products.As automation equipment suppliers, we are dedicated to supplying high-quality angle seat piston valves and other pneumatic components, meeting the valve needs of various industrial applications.

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

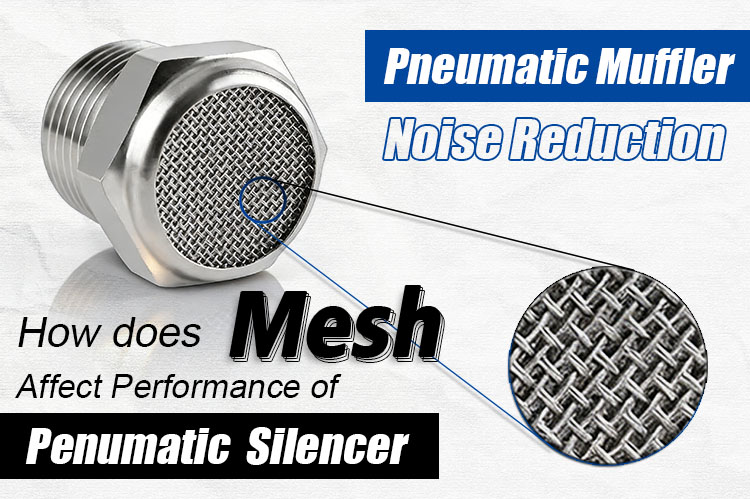

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Nov 13, 2025 Blog

How to check valve seat angle?

Nov 13, 2025 Blog

What are pneumatic angle seat valves used for?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap