Feb 07, 2026

The 2 way solenoid valve is widely used for controlling fluid flow in industrial automation. However, when installed far from the control source, long pipelines can cause action delays. Increased line resistance and volume effects slow down fluid response, affecting the overall cycle time.

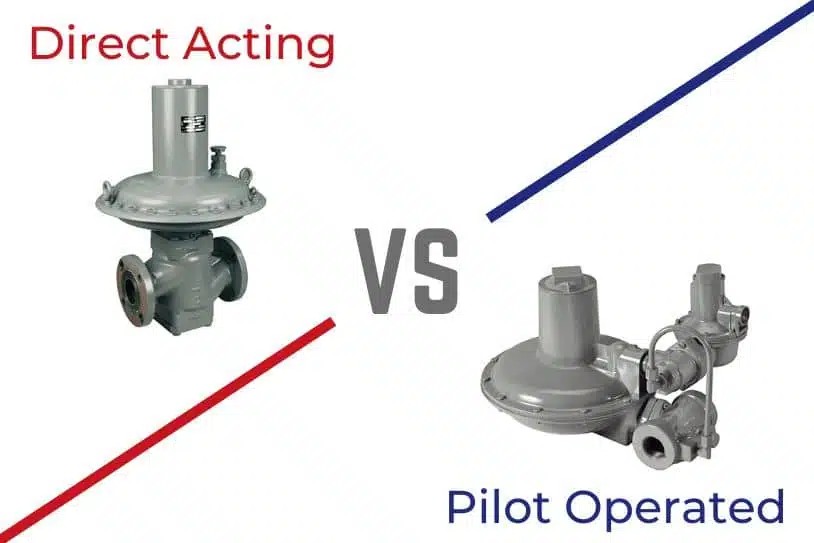

When the valve is distant from the control source, the pneumatic or hydraulic signal must travel a longer path to actuate the valve chamber. For pilot operated 2 way solenoid valve or direct acting 2 way solenoid valve, this delay directly affects opening and closing speed:

◆ Opening lag and delayed flow rise

◆ Slow closing with residual fluid

◆ Critical in high-speed cycles or precise metering

| Factor | Effect on 2-Way Solenoid Valve | Notes |

|---|---|---|

| Pipe Length | Increases fluid travel time | Longer lines = slower response |

| Line Resistance | Reduces pressure transmission | High friction = delayed actuation |

| Fluid Compressibility | Dampens signal | Gas vs liquid response differs |

| Valve Type | Direct acting vs pilot operated | Direct acting faster at short distances |

| Signal Pressure | Low pressure increases delay | Ensure sufficient actuation pressure |

Engineers can evaluate valve placement effects on cycle time by:

① Calculating fluid delay using pipe length, diameter, medium viscosity, and pressure.

② Selecting appropriate valve type, direct acting 2 way solenoid valve for long lines, or pilot-operated near control source with auxiliary pressure.

③ Increasing actuator torque to ensure reliable operation despite fluid delay.

④ Adjusting cycle timing or repositioning valves to meet system requirements.

| Parameter | Recommendation | Reason |

|---|---|---|

| Pipe Diameter | Larger diameters | Minimizes delay |

| Valve Voltage | Use 12V/24V 2 way solenoid valve | Faster coil response |

| Medium | Gas vs liquid | Liquid less compressible → faster actuation |

| Valve Placement | Closer to control source | Shortens signal travel |

| Maintenance | Check for leaks | Leaks increase response delay |

In systems such as 2 way solenoid valve for pneumatic systems or 2 way solenoid valve for water treatment, valves installed on long pipelines may experience 50–100 ms response delays. For high-speed lines or continuous filling, this delay can reduce throughput or affect metering accuracy. Solutions include:

◆ Positioning valves near air source or pump

◆ Adding auxiliary pipelines to shorten signal distance

◆ Adjusting control program timing to match actual valve response

These measures ensure stable operation, accurate flow control, and consistent system cycle time.

(FK9025)

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

You May Interest In

Dec 06, 2025 Blog

How to check pneumatic solenoid valve?

Dec 04, 2025 Blog

How does a single solenoid valve work?

Dec 03, 2025 Blog

What is double acting solenoid valve?

Dec 02, 2025 Blog

How to clean a pneumatic solenoid valve?

Dec 01, 2025 Blog

How to Wire and Install a Pneumatic Solenoid Valve?

Nov 30, 2025 Blog

How to select pneumatic solenoid valve?

Nov 29, 2025 Blog

Operational Mechanism of Pneumatic Solenoid Valves

Nov 27, 2025 Blog

What is pilot operated solenoid valve?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap