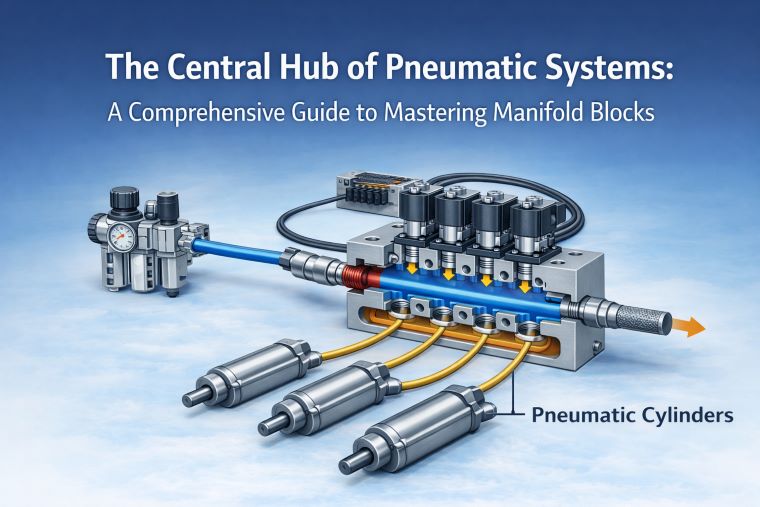

Two Types of Valve Manifolds(Air Manifold Blocks)

Valve manifold adopts both integrated and modular design structures primarily to meet the varying requirements of different industrial applications in terms of space, cost, maintenance, and system complexity.What exactly are these two types of valve islands?

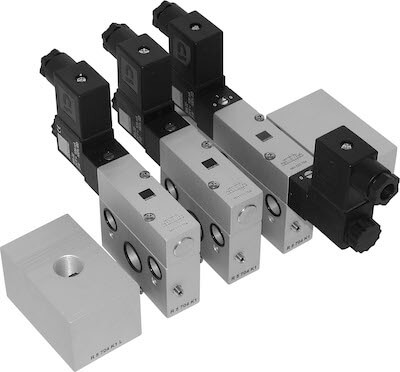

Integrated Manifold Block

Compact: The one-piece structure is small in size and easy to install.

High reliability: Fewer sealing surfaces, fewer potential leakage points.

Low cost: Suitable for applications with a fixed number of valve positions and no need for expansion.

This type is mainly based on a Valve Block machined as a single piece, with common supply and exhaust ports at both ends. The valve cores cannot be freely expanded, and the valve positions on the base plate are fixed. It is suitable for automation systems with a small number of valves and simple control requirements.

This type has fixed valve positions. Similar to a 2-valve manifold or a 3-valve manifold, although their applications differ, both belong to the integrated pneumatic valve manifold design.

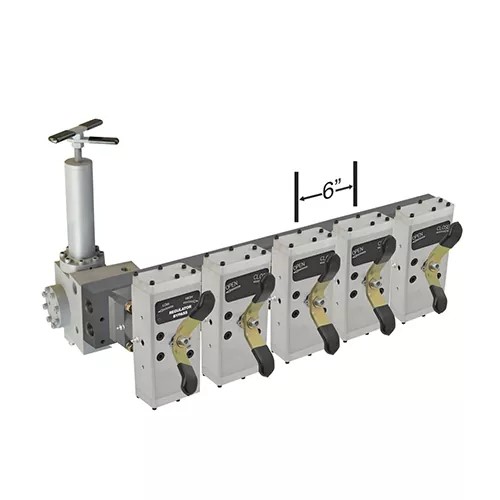

Modular Valve Manifold

Modular design manifold block means that the valve positions are modular, consisting of a common base plate with valve modules that can be flexibly added or removed at any time. Each valve position is an independent small module, and the base plate integrates pneumatic channels and electrical bus interfaces.

Advantages:

Flexible expansion: Valve positions can be added or removed as required.

Risk mitigation: A faulty valve can be replaced individually without affecting other valves.

Strong control capability: Can integrate digital input/output modules, directly functioning as I/O nodes.

Modular pneumatic valve islands are suitable for complex systems, though the cost is relatively higher.

Applications: Industries and equipment requiring reliability and expandability, such as:

Large automated production lines

Pneumatic control of industrial robots

Semiconductor equipment

Functions of a Air Manifold Blocks

Simplifies supply and exhaust piping: Multiple pneumatic solenoid valves are installed on a common base plate, sharing the supply (P) and exhaust (R/S) channels.

Centralized control: A common electrical interface connects all solenoid valves on the valve island to the PLC control system, reducing wiring complexity.

Extended control: Since valves are pneumatic components used to control actuators in automation technology, the valve manifold enables centralized control of solenoid valves, which in turn allows unified control of actuators. It systematically distributes compressed air and coordinates the push-pull and gripping actions of piston rods.

Easy maintenance: With a modular valve island design, a failure in a single valve module does not affect the entire valve island, greatly reducing downtime.

Intelligent monitoring: Multiple solenoid valves are concentrated on a single module and connected to the upper-level control system via a bus. Additionally, the valve island has internal current detection circuits, making it easier to monitor whether the solenoid coils are energized and to check the status of the solenoid valves.

Other application cases of Manifold's integrated flow channel platform

◆ Pure Air Distribution Manifold

◆ Manifold with Integrated FRL Unit

◆ Intelligent Manifold with Integrated Valves and Sensors

◆ Two-Stage Control Manifold with Pilot and Main Valves

◆ Multi-Channel Vacuum Generation and Control Manifold

FAQ

Q1.What is the purpose of a valve manifold block?

To provide a mounting base for multiple valves and distribute compressed air through shared channels, simplifying piping and making the pneumatic system more compact and organized.

Q2.What materials are valve manifold blocks made of ?

Typically made of aluminum, steel, or engineering plastics, depending on strength, weight, and corrosion resistance requirements.