Nov 10, 2025

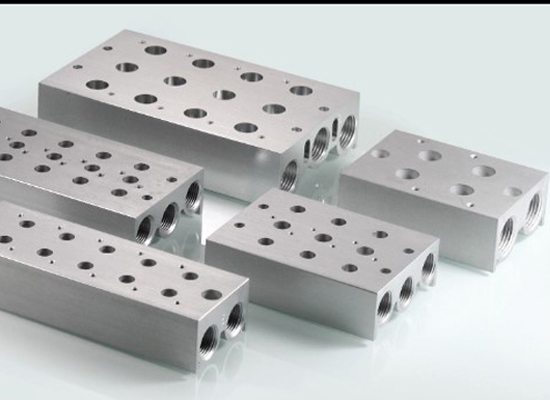

In modern pneumatic systems, efficiency is no longer defined only by component quality, but by how intelligently those components are integrated. As production lines become more compact, automated, and data-driven, the manifold block has evolved from a simple air distribution base into a critical control hub that directly affects system response speed, reliability, maintenance cost, and scalability.

This guide takes a deeper, application-oriented look at manifold blocks—how they work, why they matter in real industrial environments, and how to select the right solution for long-term system performance.

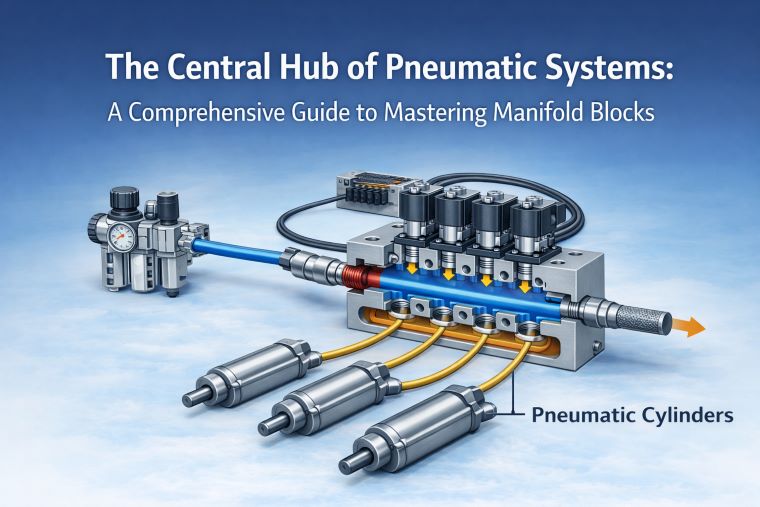

A manifold block is a precisely machined metal or engineering plastic body with integrated internal air channels and electrical interfaces, designed to centrally mount and connect multiple solenoid valves within a pneumatic control system.

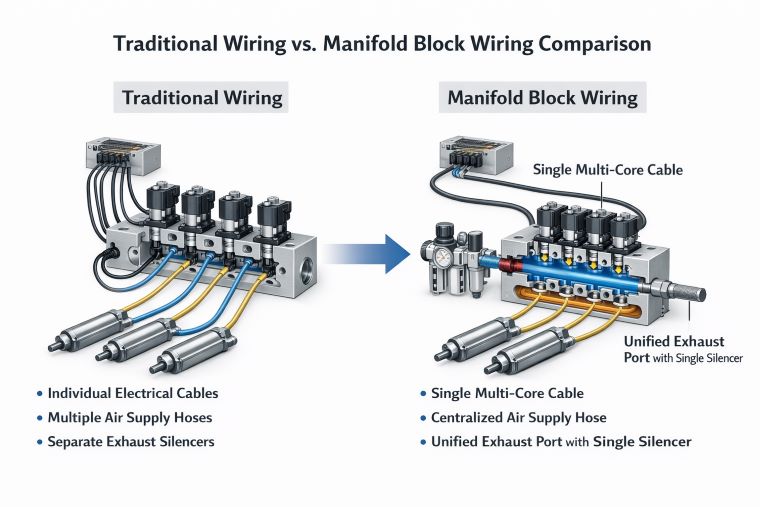

Unlike individual valve installations, a pneumatic manifold block provides shared air supply and exhaust paths, allowing multiple valves to operate from a unified pressure source. At the same time, it serves as a mechanical mounting platform that keeps valves aligned, protected, and vibration-resistant during operation.

From an electrical perspective, the manifold block consolidates power input and control signals. Instead of wiring each solenoid valve independently, a single multi-core cable or fieldbus connection delivers power and control signals to the entire valve group. Internally, these signals are distributed to each valve position, significantly reducing wiring complexity and installation time.

In practice, the manifold block is not just a mounting accessory—it is the structural and functional backbone of modern valve islands.

As the central interface between air supply, actuators, and control logic, a pneumatic manifold block integrates mechanical, pneumatic, and electrical functions into a unified system. Its operation can be understood through four functional layers.

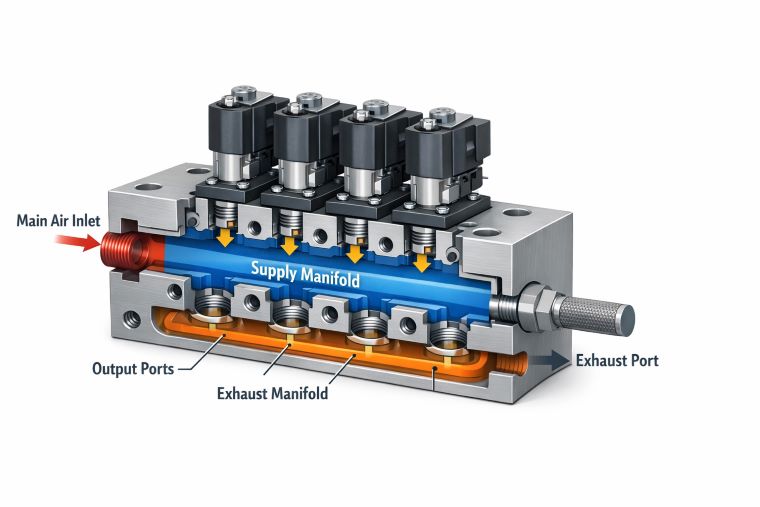

Centralized Air Supply and Distribution

Compressed air, typically conditioned by an FRL unit, enters the manifold block through a single main inlet port. Inside the block, a longitudinal supply channel distributes air evenly to each valve mounting station.

When a solenoid valve is installed, its inlet port automatically aligns with the internal supply channel via standardized sealing interfaces. This design eliminates the need for individual air hoses to each valve, reduces potential leakage points, and ensures consistent pressure delivery across all valve stations.

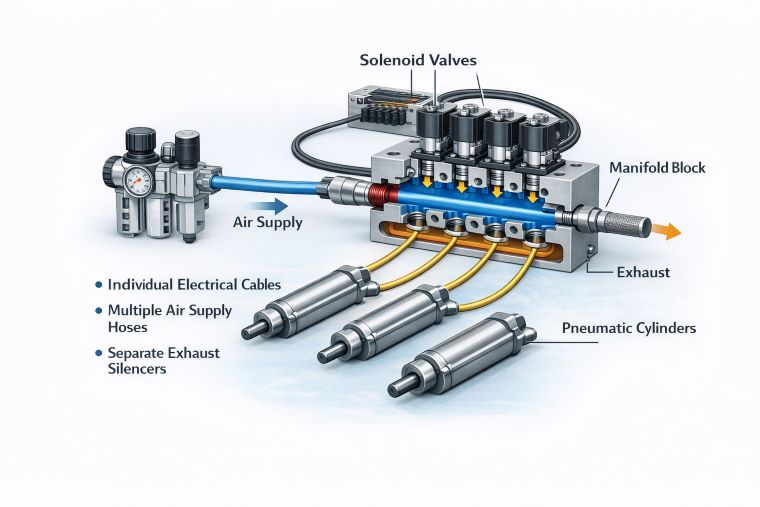

Independent Outputs to Actuators

While the air supply is shared, actuator control remains independent. Each valve position on the manifold block is connected to dedicated working ports, typically labeled A and B.

These ports are externally accessible through threaded interfaces on the manifold body. Pneumatic tubing from each port connects directly to its corresponding actuator—such as a cylinder, gripper, or rotary actuator—enabling precise one-to-one control.

The grouped and orderly arrangement of output ports simplifies tubing layout, improves readability during troubleshooting, and reduces the risk of cross-connection errors during installation or maintenance.

Unified Exhaust Management

In traditional installations, each solenoid valve vents exhaust air independently, resulting in multiple silencers, uneven noise distribution, and inconsistent exhaust back pressure.

A manifold block solves this by integrating all valve exhaust paths into one or more internal exhaust channels. These channels lead to centralized exhaust ports located on the side or end of the block.

This configuration allows:

Installation of high-capacity silencers or exhaust piping

Reduced overall noise levels

Cleaner system layouts

Easier compliance with environmental and workplace noise standards

Centralized exhaust management becomes especially valuable in high-cycle automation systems.

Electrical Control and Signal Distribution

Beyond air handling, electrical integration is where manifold blocks deliver their greatest system-level advantage.

A preassembled connector—such as a multi-pin plug or fieldbus interface—is connected to the manifold block. This single interface supplies power and control signals from the PLC or controller.

Internally, the manifold distributes:

Power via a common electrical bus

Control signals to each individual valve station

When the PLC sends a command, the signal travels through the shared cable and is routed internally to the designated solenoid coil, triggering precise valve actuation. This architecture dramatically reduces wiring errors, shortens commissioning time, and supports modular system expansion.

Although pneumatic and hydraulic manifold blocks share a similar integration concept, their design priorities differ significantly due to the nature of the working medium.

Feature | Pneumatic Manifold Block | Hydraulic Manifold Block |

Working Medium | Compressed air | Hydraulic oil |

Typical Pressure | 0.2–1.0 MPa | 7–35 MPa |

Core Materials | Aluminum alloy, engineering plastic | Carbon steel, stainless steel, high-strength alloy steel |

Sealing Focus | Prevent air leakage | Withstand high-pressure oil and temperature |

Internal Flow Design | Large cross-sections for fast response | Thick-walled, pressure-resistant channels |

Cleanliness Requirement | Standard industrial cleaning | Ultra-clean, contamination-free machining |

Surface Treatment | Anodizing | Plating, phosphating, blackening |

Valve Standards | ISO 5599-1, VDMA | CETOP, NFPA, ISO 4401 |

Primary Goal | Fast response, simplified wiring, easy maintenance | High power transmission, complex oil logic |

For most factory automation and assembly applications, pneumatic manifold blocks offer a more flexible and cost-effective solution.

Key Considerations When Selecting a Pneumatic Manifold Block

Choosing the right manifold block directly impacts system stability, scalability, and maintenance efficiency. The following factors should be evaluated during system design.

Pressure and Flow Capacity

The manifold block must safely handle the maximum system pressure, including transient spikes, while providing sufficient internal flow capacity to avoid pressure drop during peak demand.

Valve Compatibility

Ensure compatibility with the selected solenoid valve series, including mounting interface, sealing method, port alignment, and electrical connection type.

Port Configuration and Expansion Capability

Output port orientation and spacing should support clean tubing routing. Multi-station manifolds with reserve positions allow future system expansion without redesign.

Exhaust Interface Design

Exhaust port size and placement should accommodate high-efficiency silencers or centralized exhaust piping, especially in high-speed or noise-sensitive environments.

Material and Environmental Resistance

Operating conditions such as humidity, dust, chemicals, or wash-down requirements determine whether aluminum, engineering plastic, or stainless steel is the optimal material choice.

Maintenance and Modularity

A well-designed manifold block supports hot-swapping of valves, clear station labeling, and easy disassembly for cleaning—reducing downtime and service cost.

FOKCA Pneumatic Manifold Block Solutions

As a long-term pneumatic component manufacturer, FOKCA designs manifold blocks with a focus on system reliability, real-world installation efficiency, and long-term maintainability.

FOKCA pneumatic manifold blocks are engineered to:

Support mainstream solenoid valve standards

Provide stable sealing and uniform air distribution

Simplify electrical integration for PLC-based systems

Adapt to OEM and customized automation projects

Whether for compact machinery, multi-axis automation, or scalable production lines, a properly selected manifold block is not an accessory—it is the structural foundation of a high-performance pneumatic control system.

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

You May Interest In

Sep 25, 2025 Blog

What is a 2-valve manifold?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap