Feb 03, 2026

In many automation sites, a solenoid valve is installed near outdoor cabinets, compressed air pipelines, or refrigeration equipment. When the day–night temperature difference is large, condensation easily forms on the coil and valve body surface. These small water droplets can become a critical factor affecting the reliability of industrial solenoid valves. Understanding how condensation forms and how it influences both electrical and mechanical parts is essential for stable operation.

Moisture in the air turns into liquid once the surface temperature falls below the dew point. The housing of a pneumatic solenoid valve usually dissipates heat quickly, becoming a cold spot at night. Expansion of compressed air can further reduce local temperature, making the valve continuously wet. Repeated temperature cycles accelerate aging of insulation and seals used in solenoid valve for pneumatic systems.

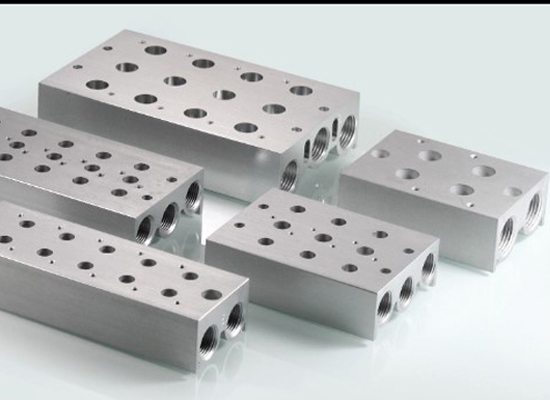

Condensed water first threatens the coil and connectors. When moisture penetrates terminals, leakage current or short circuit may occur, especially under different solenoid valve coil voltage comparison conditions. Oxidation of copper wire increases resistance and reduces magnetic force, leading to slow action of normally closed solenoid valve or normally open solenoid valve. In a solenoid valve manifold, several valves share one enclosure, so humidity is harder to release and failures may appear simultaneously.

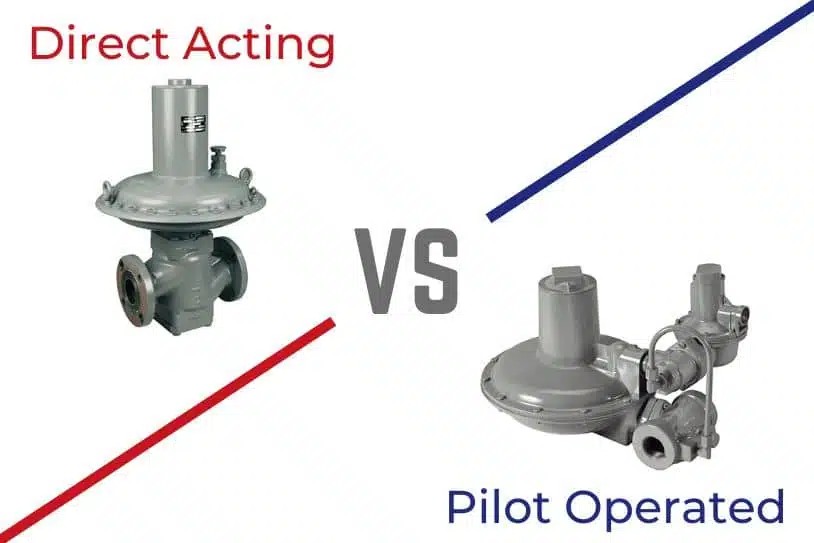

The movement of the plunger is the heart of any direct acting solenoid valve. Once water enters the core tube, surface tension increases friction and the plunger may not reach full stroke. Even a pilot solenoid valve can suffer from insufficient pilot pressure. Long-term water film carries tiny particles and works like abrasive paste, shortening service life of automatic solenoid valve.

| Application scenario | Main risk from condensation | Possible result |

|---|---|---|

| Compressed air system | Water in core tube | Delayed response |

| HVAC system | Coil moisture | Insulation aging |

| Outdoor cabinet | Repeated dew | Connector corrosion |

| Water treatment | High humidity | Seal deformation |

In solenoid valve in HVAC systems and solenoid valve in water treatment, humidity is already high, so the impact becomes more obvious. For devices requiring precise timing such as pulse solenoid valve or high speed solenoid valve, even slight delay destroys process rhythm.

Choosing a suitable product is the first defense. Low power solenoid valve generates less heat difference and reduces dew formation. Waterproof breathing structure, anti-corrosion connectors, and products designed as solenoid valve for automation are practical choices. In compressed air lines, proper drying improves the working condition of solenoid valve for compressed air and benefits overall solenoid valve flow control.

During solenoid valve maintenance and troubleshooting, condensation should be treated as a major risk equal to dust. Regular inspection of seals, keeping ventilation around the coil, and avoiding direct contact with cold pipelines are effective measures. For critical equipment, monitoring solenoid valve response time and cycle life helps to detect early symptoms of moisture intrusion.

Condensation seems minor, yet it challenges both the electrical and mechanical nature of every industrial automation solenoid valve uses. A well-considered solenoid valve selection guide that includes temperature difference factors can greatly improve long-term reliability of any automated system.

(FK9025)

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

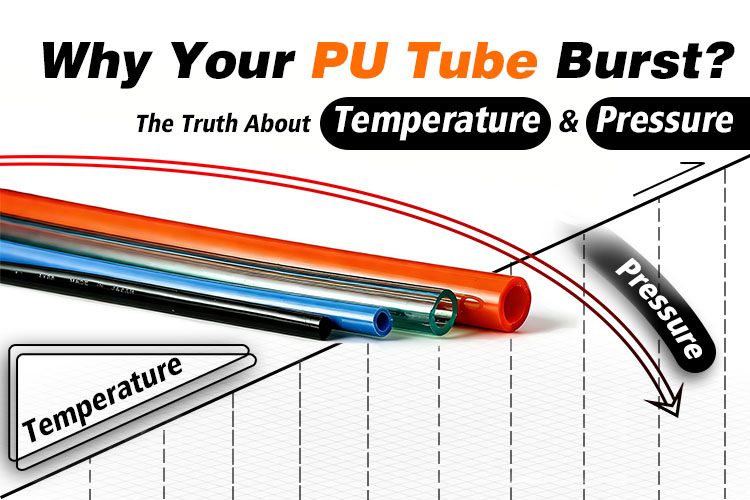

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

You May Interest In

Dec 06, 2025 Blog

How to check pneumatic solenoid valve?

Dec 04, 2025 Blog

How does a single solenoid valve work?

Dec 03, 2025 Blog

What is double acting solenoid valve?

Dec 02, 2025 Blog

How to clean a pneumatic solenoid valve?

Dec 01, 2025 Blog

How to Wire and Install a Pneumatic Solenoid Valve?

Nov 30, 2025 Blog

How to select pneumatic solenoid valve?

Nov 29, 2025 Blog

Operational Mechanism of Pneumatic Solenoid Valves

Nov 27, 2025 Blog

What is pilot operated solenoid valve?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap