Feb 03, 2026

In modern commercial vehicles, the reliability of braking systems is heavily influenced by the tubing material. Nylon air brake tube has become the preferred choice over PU tubes due to its superior performance in extreme temperature ranges, high-pressure tolerance, and long-term durability. Choosing the right Air Brake Tubing ensures safer operation, lower maintenance, and longer service life for trucks and trailers, especially in cold regions of North America and Europe.

One of the key advantages of nylon air brake line is its stable hardness across a wide temperature range, from –40°C to 100°C. Nylon’s semi-crystalline molecular structure resists sudden hardening at low temperatures and prevents softening or expansion at high temperatures. In contrast, PU tubes can stiffen or become brittle in cold conditions and may soften under engine heat, risking deformation and delayed brake response.

Key point: Nylon maintains predictable mechanical properties across extreme climates, making it ideal for winter operations and hot engine compartments.

Air brake systems typically operate at 8–12 bar, with potential pressure spikes higher than 20 bar. Nylon air brake tube offers superior tensile strength and burst pressure resistance compared to standard PU tubes. PU tubing under high pressure may develop micro-cracks or bulges, eventually leading to failure, while nylon reliably withstands both continuous and shock pressures.

Conclusion: Nylon provides a safer and more robust solution for critical air brake circuits.

Nylon tubing has a smooth, durable surface that resists abrasion from chassis vibration and contact with mounting hardware. It also exhibits strong resistance to chemical exposure from gasoline, engine oil, and brake fluids. PU tubes, however, can degrade faster under long-term exposure to oils, UV radiation, or repeated friction.

| Property | Nylon Air Brake Tube | PU Tube | Performance Impact |

|---|---|---|---|

| Abrasion Resistance | High | Moderate | Reduced wear risk |

| Chemical Resistance | Strong | Moderate | Longer life in oily environments |

| UV Stability | Good | Limited | Fewer replacements |

This makes nylon air brake tube particularly suitable for heavy-duty and cold-weather operations.

Despite its strength, nylon tubing remains lightweight and maintains its circular cross-section even when bent. This ensures consistent airflow and prevents collapse. PU tubes, being softer, may flatten or deform when routed over long distances, potentially affecting brake response time.

Tip: Choose tubing with proper bend radius specifications to ensure maximum airflow and system safety.

1.Tractor-trailer service brake lines

2.ABS/EBS signal tubing

3.Air suspension circuits

4.Vehicles operating in winter conditions or engine compartments

For these applications, nylon air brake tube ensures reliable braking performance under temperature fluctuations, vibration, and chemical exposure.

1.Confirm operational temperature range matches the vehicle’s climate conditions.

2.Verify burst pressure and compliance with SAE J844 or DOT standards.

3.Ensure tubing outer diameter matches fittings for a secure connection.

4.Opt for UV-resistant and oil-resistant grades when exposed to engine heat.

5.Consider color-coded tubing for easier circuit identification.

Better material selection = safer braking + lower maintenance cost.

When it comes to air brake systems, material choice is not optional. Compared with PU tubes, nylon air brake tube provides superior temperature stability, burst resistance, wear and chemical durability, and dimensional consistency. Selecting certified Air Brake Tubing is a simple yet effective way to improve fleet safety and minimize downtime.

(FK9026)

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

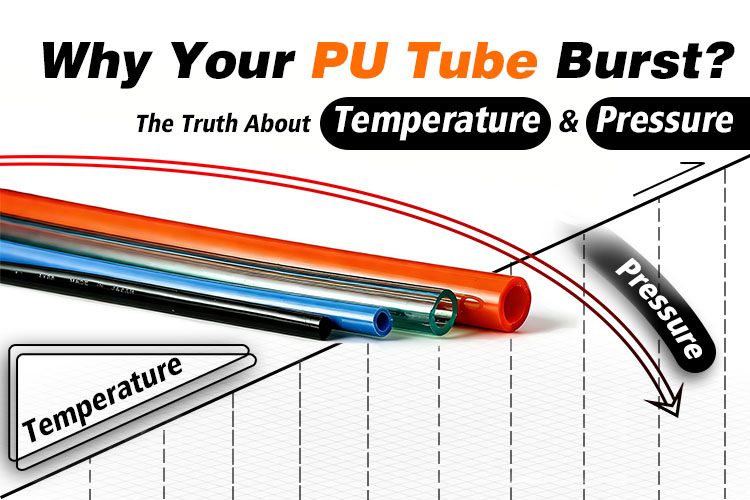

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

Temperature Difference: Influence of Condensation on Solenoid Valve Reliability

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap