Jan 29, 2026

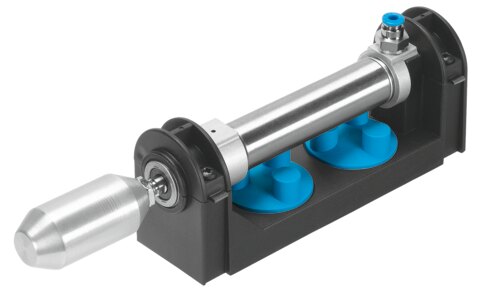

In industrial automation, air cylinders are rarely chosen because they are simple or inexpensive. They are chosen because, when applied correctly, they offer predictable motion, fast response, and long-term stability with relatively low system complexity. For automation designers, maintenance engineers, and procurement teams, the real value of air cylinders appears not in datasheets, but in how they behave under real operating conditions—continuous cycles, pressure fluctuations, and unplanned stops.

An air cylinder converts compressed air into linear mechanical motion. At the most basic level, this sounds straightforward. In practice, the cylinder becomes the final physical link between the control system and the machine’s mechanical outcome. Every extension, return, and stop point directly affects product quality, safety margins, and cycle time consistency.

This is why experienced engineers rarely ask only “how much force is needed.” They ask how often the cylinder will cycle, what happens when air pressure drops, and whether the actuator must return to a defined position without relying on control logic.

In controlled laboratory conditions, most cylinders perform as expected. On the factory floor, however, air cylinders operate in environments where pressure varies, seals age, lubrication degrades, and loads change over time. The design challenge is not achieving motion once, but ensuring the same behavior thousands or millions of cycles later.

For high-speed packaging lines or pick-and-place units, the priority may be repeatability and response time. In clamping, guarding, or vertical applications, predictable behavior during shutdowns or pressure loss often matters more than speed. These competing priorities shape how cylinders are selected and integrated.

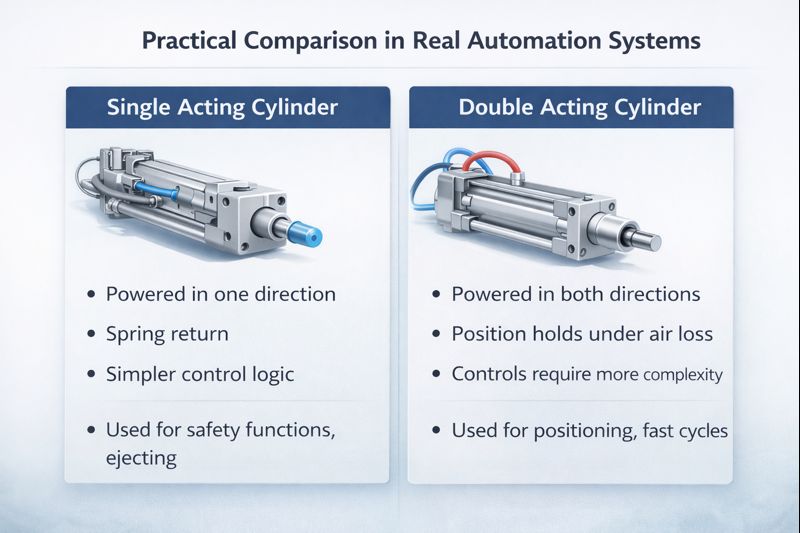

The distinction between single acting cylinders and double acting cylinders is often introduced as a basic classification. In real automation design, it represents a deeper choice about how system behavior is managed.

A single acting cylinder uses compressed air for motion in one direction, with a mechanical element—usually a spring—defining the return position. This creates a known default state when air supply is removed. A double acting cylinder, by contrast, relies on air pressure for both extension and retraction, offering greater control flexibility but no inherent return behavior.

This difference becomes important not during normal operation, but during abnormal conditions: emergency stops, maintenance, or supply interruptions. At that point, the cylinder is no longer just an actuator—it becomes part of the system’s risk management strategy.

In mature automation projects, engineers often design from the failure case backward. If a gripper loses air, should it hold the part or release it? If a stopper retracts unintentionally, will it cause a jam or prevent one? These questions directly influence whether a single acting air cylinder or a double acting air cylinder is appropriate.

Single acting designs embed part of the safety logic into the mechanical structure itself. Double acting designs push that responsibility into the pneumatic circuit and control system. Neither approach is universally better, but choosing without considering failure behavior usually leads to unnecessary complexity later.

Aspect | Single Acting Cylinder | Double Acting Cylinder |

Motion control | One powered direction | Powered in both directions |

Behavior on air loss | Returns to fixed position | Position depends on load and circuit |

Control complexity | Lower | Higher |

Typical applications | Clamping, ejecting, safety stops | Positioning, pushing, high-speed cycles |

System dependency | Mechanical default state | Control and valve dependent |

This comparison is less about performance and more about predictability. In systems where failure behavior must be clearly defined, designers often accept reduced control flexibility in exchange for mechanical certainty.

While formulas can estimate theoretical output force, experienced engineers know that usable force in an air cylinder is influenced by seal friction, pressure stability, and installation alignment. Single acting cylinders further reduce available force due to spring resistance, which must be accounted for during sizing.

Double acting cylinders avoid this limitation and are preferred where consistent bidirectional force is required. However, this advantage comes at the cost of increased reliance on valves, sensors, and air quality. Over time, system tuning becomes as important as initial selection.

Cylinder orientation is often underestimated during design. Vertical installations, especially those handling suspended loads, magnify the importance of return behavior. In such cases, a single acting cylinder can simplify mechanical design by defining a gravity-assisted or spring-driven default state.

Maintenance engineers often favor designs where the cylinder’s behavior remains intuitive even when parts are worn. Systems that rely entirely on control logic tend to demand stricter maintenance discipline to avoid unpredictable motion.

As automation systems mature, standard pneumatic air cylinders may no longer meet space, stroke, or environmental requirements. Extended stroke applications, compact installations, or corrosive environments often require customized solutions. This is where OEM and ODM capabilities become relevant—not for performance gains alone, but to maintain predictable behavior under non-standard constraints.

Customization is less about uniqueness and more about preserving system logic when standard dimensions or materials no longer apply.

Despite advances in electric actuators, air cylinders continue to dominate many automation sectors because they balance simplicity, durability, and controllability. When selected with attention to failure behavior, installation context, and long-term operation, they remain one of the most reliable motion solutions available.

For engineers and decision-makers, the real question is not whether air cylinders are suitable, but whether their role in the system has been fully understood before selection.

(FK9027)

How Air Cylinders Are Actually Used in Industrial Automation Design

How Air Cylinders Are Actually Used in Industrial Automation Design

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

You May Interest In

Nov 12, 2025 Blog

What is a single acting cylinder?

Nov 06, 2025 Blog

Why choose a single acting pneumatic cylinder?

Dec 04, 2025 Blog

How does a single solenoid valve work?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap