The working principles of single-acting pneumatic cylinders and single-acting hydraulic cylinders also differ. The following section mainly introduces the single cylinder action and industrial applications.

Nov 06, 2025

Single-acting and double-acting are the two basic actuation types of pneumatic air cylinders. The main difference between them lies in the way compressed air drives the piston's movement inside the cylinder.A single-acting cylinder is an kind of easy pneumatic actuator that uses compressed air to generate force in one direction, while returning in the opposite direction through a internal spring or external force. Understanding how a single-acting cylinder works can make your pneumatic system more effective and efficient.

However, actuators can also be classified into hydraulic and pneumatic types, with the main difference being the driving medium used. As one of the two actuation modes of cylinders, the single-acting type naturally exists in both hydraulic and pneumatic actuator forms.

What is a single-acting cylinder or actuator, and why choose one? A single-acting pneumatic cylinder is powered by compressed air, using air pressure to move in only one direction while a spring provides the return motion.

The single-acting cylinder offers distinct advantages over its more complex double action cylinder. Its compact and lightweight design ensures easy installation and operation. Being more energy-efficient and environmentally friendly, it only consumes compressed air during the piston's extension stroke. Furthermore, its relatively moderate output force makes it ideally suited for light-duty applications like pushing, lifting, and clamping.

This article will explain why you might choose a single-acting cylinder instead of a double-acting one, how it works, and its common applications.

Clamping-The workpiece can be secured in place by jaws driven by the cylinder. When compressed air enters, the piston pushes the jaws to clamp the workpiece, making it ready for subsequent processing. After the operation is completed, the air supply is cut off, and the spring returns the jaws to their open or retracted position.

Positioning-A single-acting cylinder can be used to push or pull a workpiece into an exact position. Once the movement is completed, the spring automatically returns the piston to its initial position, preparing the cylinder for the next cycle.

Pressing-The output stroke of the piston rod can be used for pressing, clamping, or marking actions. When the compressed air is released, the spring automatically retracts the punch, ready for the next operation.

Packaging: Due to their moderate force output and rapid response, single-acting cylinders are suitable for actions such as pushing, sorting, and counting small items, as well as opening bags, labeling, and gently lifting soft packaging after filling.

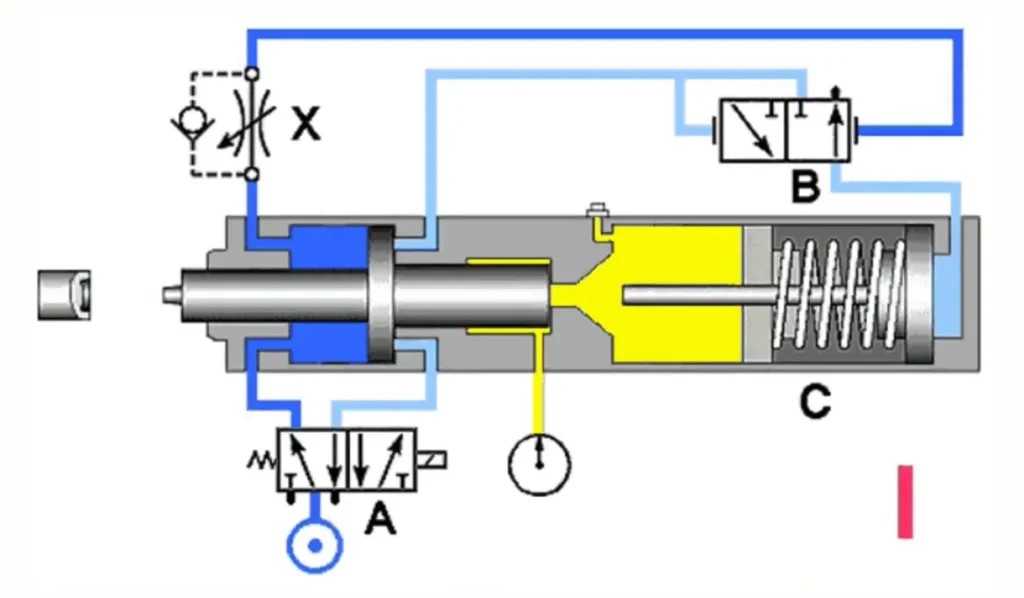

Single acting cylinder work mode is a type of linear reciprocating action.

The working principle of a single-acting cylinder is somewhat similar to that of a double-acting cylinder, yet not exactly the same. In both types, the piston rod is driven by compressed air supplied through the air line. However, in a single-acting cylinder, when the piston is pushed by compressed air, it must first overcome the spring's initial tension. Part of the air pressure is therefore converted into spring force, which reduces the cylinder's actual output force compared to its theoretical value. In contrast, a double-acting cylinder has no spring structure, so all the air pressure is used directly for motion.

Piston rod extension: Compressed air enters the cylinder barrel and acts on the piston, pushing the piston rod to move linearly. During this process, part of the air pressure is converted into spring force while driving the load.

Piston rod return: When the compressed air is released from the inlet port, the spring's elastic force pushes the piston rod back to its original position.

Low cost: A single-acting cylinder requires only one air inlet and uses a spring for the return stroke, making its structure simpler and its manufacturing and maintenance costs lower than those of a double-acting cylinder.

Energy-saving and environmentally friendly: The piston rod extends using compressed air and returns via the spring, consuming less air than a double-acting cylinder and therefore being more energy-efficient.

Easy installation: It only requires one air supply line and a simple valve control system.

Suitable for light-load applications: Due to the limited spring force, the effective stroke and output force are smaller, making it more suitable for light-duty operations compared to a double-acting cylinder.

Safe: The spring mechanism ensures that the piston rod automatically returns even in the event of air supply failure or emergency shutdown, providing greater safety.

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Does Nylon Tubing Become Brittle in Low-Temperature Environments

Does Nylon Tubing Become Brittle in Low-Temperature Environments

You May Interest In

Nov 12, 2025 Blog

What is a single acting cylinder?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap