Dec 17, 2025

Pneumatic systems are mainly used to achieve automation control and mechanical power output.

They use compressed air as the power source to realize linear motion, rotary motion, and gripping actions of equipment, and are widely used in automated production lines as well as in the driving, control, and execution of mechanical equipment.

(1)Air Generation and Preparation

Air Compressor: Compresses atmospheric air into pressurized air, serving as the power source of the system.

Receiver Tank (Air Reservoir): Stores compressed air to provide a stable air supply.

Air Treatment Unit (FRL Unit): Includes components such as filters, regulators, and lubricators to remove contaminants and moisture, regulate air pressure, and sometimes lubricate components to ensure smooth system operation.

(2)Control and Transmission

Control Valves: Used to direct, start, stop, or change the direction of airflow in the system. They work with PLC-based remote control systems to achieve automated control.

Fittings and Tubing: Hoses and connectors that transport compressed air between components. They must ensure stable transmission and excellent sealing performance.

Sensors and Switches: Monitor pressure or position and provide feedback signals, forming a closed-loop control system together with the control valves.

(3)Output (Actuation)

Pneumatic Actuators: Convert compressed air into mechanical energy in the form of linear motion (cylinders) or rotary motion (pneumatic motors) to perform work, such as cylinders, motors, and grippers.

The main components that make up a pneumatic system are the following six parts.

Air Source Unit:

Provides compressed air;common components include air compressors and air receiver tanks.

Air Treatment Components:

Also commonly referred to as the FRL unit, air source treatment unit, or air preparation unit, used to clean and regulate compressed air. They mainly include:filters, regulators, and lubricators.

Control Components:

Used to control the direction, pressure, flow rate, and on/off of compressed air, such as:angle seat valves, directional control valves, pressure control valves, and flow control valves.

Actuators:

Convert the energy of compressed air into mechanical motion. Common types include:pneumatic cylinders and rotary actuators.

Auxiliary Components:

Used for connecting, installing, and protecting the system, such as:tubing, fittings, silencers, pressure gauges, and safety valves.

Monitoring and Control Devices (Optional):

Used for monitoring and automatic control, such as:pressure switches, limit switches, sensors, and PLCs.

Pneumatic components are the parts of a pneumatic system that generate, control, transmit, and use compressed air, such as air sources, valves, tubing, and actuators.

A pneumatic cylinder provides straight-line (linear) motion.

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

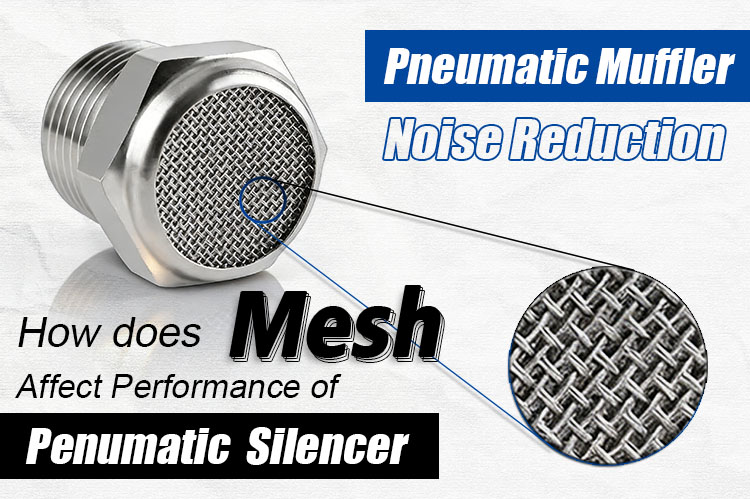

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap