Dec 16, 2025

In many industrial fields, pneumatic cylinders are the fundamental and key actuating components in pneumatic systems for achieving linear motion. Powered by compressed air, they reliably and accurately convert pneumatic energy into linear mechanical movement, and are widely used in applications such as lifting, pushing, clamping, and pressing. With advantages including simple structure, fast response, high energy efficiency, and reliable operation, pneumatic cylinders have become indispensable core components in automated production.

Next, we will take an in-depth look at the working principles and structural characteristics of pneumatic cylinders that enable linear motion. After reading this article, you will gain a clear understanding of the differences between various types of pneumatic cylinders and be able to select the most suitable linear-motion actuator based on your specific application requirements. Stay tuned!

A pneumatic cylinder (also known simply as a cylinder) is a simple device that uses compressed air to generate linear motion. It operates much like a push–pull mechanism driven by compressed air. This type of motion is extremely useful for tasks such as opening and closing doors, moving objects, and even rotating mechanical arms on wearable belts.

Pneumatic cylinders come in a wide variety of configurations and models, but their primary function—producing straight-line motion—remains the same. Compared with electric or hydraulic cylinders, they are quieter in operation, more cost-effective, and easier to use.

Pneumatic cylinders are widely used across various industries and come in many types, each suited to different application scenarios. Next, we will introduce several common types of pneumatic cylinders to help you choose the model that best meets your needs.

Definition: A single-acting cylinder is driven by compressed air in only one direction. The return stroke is typically completed by spring force or an external load.

Commonly used for simple pushing or ejecting actions, applications with low reset requirements, and equipment with limited space and simple structural requirements.

Precautions: Output force is relatively small during the return stroke; springs are prone to fatigue; long-term use requires maintenance and upkeep; stroke is generally short, unsuitable for high-frequency or long-stroke applications.

Definition: A double-acting cylinder allows compressed air to flow through both sides of the piston, enabling reciprocating linear motion. Both the forward and outward directions are driven by air pressure.

Commonly used in automated production lines for actions such as pushing, clamping, positioning, and conveying, where precise control and stable output force are required.

Precautions: Pneumatic control is relatively complex; energy consumption is slightly higher than that of a single-acting cylinder; remote automatic control with a solenoid valve is required.

Definition: A rodless cylinder drives the load through an internal or external connection mechanism (such as magnetic coupling or mechanical connection), without using a traditional piston rod.

Commonly used in long-stroke linear motion, equipment with limited space but requiring a large stroke, and automated handling and positioning systems.

Precautions: Requires high installation precision, has limited load-bearing capacity, usually requires external guidance, and is relatively expensive.

Definition: A rotary cylinder converts compressed air into angular rotational motion, commonly with rotation angles of 90°, 180°, or 360°.

Commonly used in workpiece flipping and rotation, direction switching devices, and automated assembly and sorting systems.

Precautions: Rotation angle and torque are adjustable; avoid overloading; pay attention to buffering and positioning accuracy.

Automated production lines

Used for pushing, positioning, sorting, and assembling workpieces.

Material handling and conveying

Enable lifting, pushing and pulling, clamping, and directional movement.

Packaging industry

Applied in sealing, cutting, pressing, filling, and labeling processes.

Machinery manufacturing and processing

Used for fixture clamping, auxiliary stamping operations, and workpiece positioning.

Automotive industry

Applied in welding, assembly, inspection, and material handling operations.

Electronics and semiconductor industry

Suitable for high-frequency, high-precision, low-load linear motion control.

Load and output force

Determine the cylinder bore based on the required pushing or pulling force under actual working conditions, while also considering an appropriate safety factor.

Stroke length

Confirm the required linear travel distance and select a cylinder with a stroke that meets or slightly exceeds this requirement.

Cylinder type

Choose a single-acting or double-acting cylinder according to the motion requirements; select standard cylinders, compact (thin) cylinders, rodless cylinders, etc., based on the operating environment and application.

Mounting method

Select suitable mounting brackets, as different mounting configurations can affect the stability and service life of the cylinder.

Selecting the right pneumatic cylinder is crucial for the manufacturing industry, as it directly affects equipment performance, production efficiency, and operating costs. A properly selected cylinder can provide stable and reliable linear motion, ensure precise actions and consistent cycle times, and thereby improve product quality and overall productivity.

Therefore, choosing the appropriate cylinder based on factors such as load, stroke, mounting method, working environment, and operating frequency is a fundamental requirement for ensuring the efficient, stable, and long-term operation of automated equipment.

(FK9016)

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

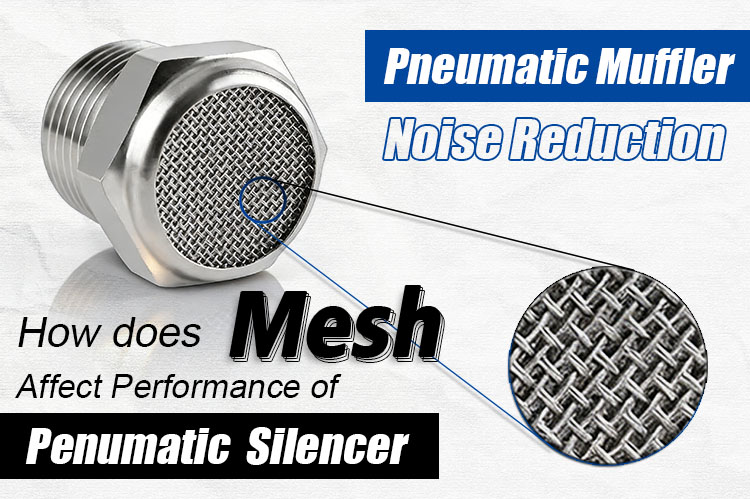

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

May 06, 2025 Blog

A Complete Guide to Pneumatic ComponentsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap