Different components structure: Hydraulic components are usually heavier and have higher sealing requirements; Pneumatic parts have a simple structure and are easy to maintain.

May 06, 2025

In today's industrial era, which emphasizes efficiency and automation, pneumatic technology has emerged as a mature and reliable power solution. With advantages such as safety, cost-effectiveness, and simple maintenance, pneumatic systems are being widely adopted across various industries. Utilizing compressed air from atmosphere as an energy carrier, pneumatic systems offer simpler equipment structures, lower energy consumption, and cleaner operation compared to hydraulic or electric drive systems. They are especially well-suited for applications requiring frequent movement, rapid response, or high cleanliness standards.

A complete pneumatic system generally consists of five key stages: intake, compression, regulation, control, and actuation.

Intake: The air system draws air from the atmosphere, Stored in gas cylinders and prepare it for compression.As an input for pneumatic systems.

Compression: The air is compressed by a compressor and stored in an air tank under high pressure environment and wait filtering and other procedures.

Regulation: Using filters, regulators, and lubricators to deal with compressed air.

Control: Pneumatic valves control the direction, pressure, and timing of airflow to Air autuator.

Actuation: Under the action of the cylinder, converting air force into mechanical energy for linear or rotary motion.As the output power of the pneumatic system.

Through the various stages and functions of different pneumatic components mentioned above, the compressed air meets our usage requirements.By understanding each stage and relevant parts , you can gain a deeper understanding of the role and advantages of pneumatic systems.

These devices supply continuous and stable compressed air to all pneumatic components. They draw in atmospheric air, compress it to the required pressure, and store it—serving as the system's power source.

These units Played as air preparation units in pneumatic systems which remove water, oil mist, and particulate contaminants from stored compressed air, improving air quality and protecting downstream components from contamination or corrosion.

The components related to control and regulation of pneumatic systems include Pneumatic Filters, Regulators, Lubricants, and Valves.

Used for further air purification, these filters remove solid particles, moisture, and some oil from compressed air to keep systems clean and prevent pipe or valve blockages and wear.

If the initial air pressure is too high for downstream components, pneumatic regulators adjust it to a stable, required level to protect equipment and ensure proper operation.

In high-speed or heavy-load systems, a small amount of oil is added to compressed air to lubricate downstream cylinders and valves, reducing wear and extending component life.

As the "control center" of the system,like regulators, filters, and lubricators, Pneumatic valves is also a type of pneumatic control system components.Pneumatic valves direct airflow and regulate pressure and timing. Common types include solenoid valves, manual valves, check valves, and flow control valves.The typical Applications of valve Include:Assembly lines,Packaging machinery and Logistics and handling systems.

Fokca offers various professional pneumatic system components, This includes valve types with 2/2, 3/2, 5/2, 5/3 control modes, available in solenoid, manual, air-pilot, and mechanical actuation options. Fokca's innovative coil and sealing component design ensures fast, stable switching and high sealing performance. Can effectively maintain the airtightness of the pneumatic system.

Alternatively, you can browse our valve blog to gain knowledge about valves.

As the core actuators parts in pneumatic systems, cylinders convert air from atmosphere pressure into linear motion for pushing, clamping, lifting, and other mechanical actions. Common types include single-acting, double-acting, and rodless cylinders.

Can be widely used In multiple pneumatic system scenarios which include automated assembly lines,packaging equipment and automotive production.

Fokca offers standard, compact, rodless, and double-shaft cylinders to meet various installation and stroke requirements. Features include:

High-strength aluminum alloy body

Smooth inner walls

Fast response

Long service life

Flexible tubes that connect different pneumatic components and transport compressed air.

Fokca offers pneumatic hoses in polyurethane , nylon , polyethylene , and rubber to suit various pressure, temperature, and flexibility needs. Key features include:

High-strength materials and precision manufacturing

Continuous operation under high PSI

Bend resistance and excellent flexibility

Typical Applications Include:

Industrial automation equipment

Automotive assembly lines

Packaging machinery

Essential fittings for constructing complete pneumatic pipelines, ensuring leak-proof connections and easy installation. Used to connect hoses, valves, cylinders, etc.

Fokca offers a wide variety of fittings including straight, elbow, tee, Y-type, and cross types to meet diverse installation needs. Features include:

Quick-release structure for one-handed operation

High-elasticity seals and precision threads for long-term leak-free use

Available in brass, stainless steel, and plastics

Typical Applications Include:

Automated production lines

Assembly and manufacturing industries

Pneumatic tools

The pneumatic hose and connectors in the pneumatic system together form the pneumatic piping system, which is responsible for transporting compressed air medium.

In modern manufacturing and industrial automation systems, pneumatic actutors play the role of a "power output arm" in pneumatic system. Whether in repetitive assembly line tasks or precision assembly processes, cylinders provide reliable force with fast response and high efficiency.

Automated Assembly Lines:Cylinders handle grabbing, pushing, positioning, and pressing, ensuring precise production rhythm.

Material Handling and Transfer:Cylinders drive conveyor platforms, slides, or lifting mechanisms to improve material flow efficiency and reduce manual labor.

Welding Fixtures and Positioning Tools:Cylinders manage clamping and releasing actions to enhance welding accuracy and safety, often in automotive parts manufacturing.

Fast Response & High Repeatability:

Meet strict cycle control in high-speed automation.

Diverse Specifications & Customization:

Support various bore sizes, strokes, and mounting options to suit equipment layouts.

◆ Regularly inspect pneumatic system components for leaks, wear, or damage.

◆ Keep the air clean and replace the filter regularly.

◆ Properly lubricate to ensure the smooth operation of the lubricator.

◆ Check the tightness of the pneumatic hoses and fittings.

Different working media: Due to the different media used in the two systems, hydraulic system components are superior to pneumatic system components in terms of corrosion resistance, high rigidity and stability, lubrication, and impact resistance.

Different pressure ranges: Because pneumatic system parts adopt lightweight design and cost control, their applicable pressure range is more limited compared to hydraulic system parts.

In an era striving for efficiency, intelligence, and sustainability, pneumatic technology is rapidly transforming manufacturing methods and boosting productivity. As a key driver of this transformation, BLCH is dedicated to delivering stable, reliable, and innovative pneumatic components and solutions to customers worldwide.

Whether you are in manufacturing, medical equipment, food processing, electronics assembly, automated logistics, or automotive engineering, we can provide tailored pneumatic solutions based on your industry needs and equipment characteristics—helping you achieve higher levels of automation and productivity.

At Fokca, we don't just supply products—we aim to drive the intelligent transformation of the manufacturing sector.We believe:Every driving force is a bridge to the future of industry.

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

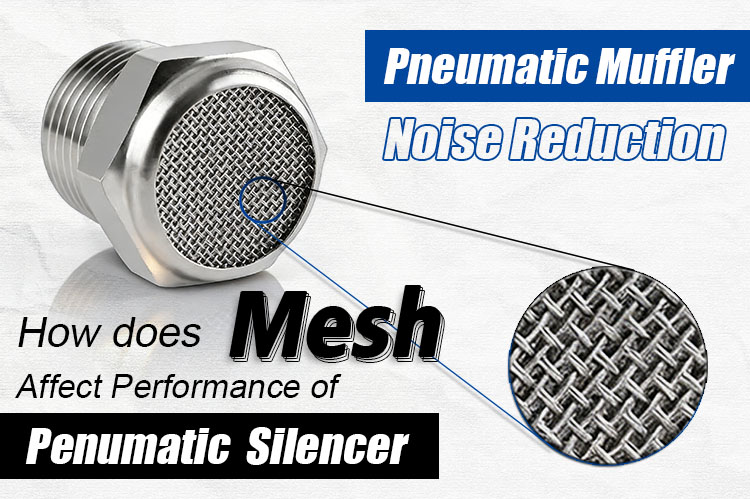

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap