- sales@fokca.com info@fokca.com

- WhatsApp: +86 150 5749 1870

Aug 12, 2025

Solenoid valves are key components for fluid control in automation systems, mainly divided into two types: pilot-operated and direct-acting. This article will take you through a complete understanding of their working principles and structure.

A solenoid valve is a component that remotely regulates valve opening and closing by electromagnetic force to achieve automated fluid control.

· Power On: Applying current to the coil generates a magnetic field, which moves the plunger to open the valve.

· Power Off: When not energized, the valve stays in its default position—either open or closed.

· Fluid Flow: The valve maintains fluid flow by being fully open or blocks flow by being fully closed.

· Power Off Again: Cutting off current causes the sealing element to return to its default position.

In general, direct-acting solenoid valves are not suitable for regulating flow.

2-way: One inlet and one outlet; suitable for simple on/off control.

3-way: One inlet and two outlets; used to change fluid direction.

4-way: Two inlets and two outlets; used for more complex flow control.

General Solenoid Valves: Control fluid on/off, usually without flow regulation.

Pneumatic Solenoid Valves: Control pneumatic actuators, suitable for large diameter and high-pressure, high-thrust industries.

Pulse Solenoid Valves: Fast response with high-speed compressed air flow, commonly used in dust removal systems.

Enquire more solenoid valve types in our fokcaflow website.

These valves use a small pilot valve to control the main valve. When energized, the pilot valve opens, releasing medium into the main valve chamber, creating a pressure difference that moves the main valve spool to open the passage; when the pilot valve closes, the main valve closes accordingly.

Direct-acting valves operate without a pilot valve. The coil’s magnetic field directly drives the solenoid to open or close the valve spool.

Pressure: Pilot-operated valves can handle higher pressures.

Flow Rate: Pilot-operated valves are better suited for high flow applications.

Speed: Direct-acting valves respond faster.

Power Consumption: Direct-acting valves generally consume less power.

Both direct-acting and pilot-operated valves rely on electromagnetic force to drive the valve spool either directly or indirectly.

These valves are used in:

Agricultural Machinery: For irrigation systems and hydraulic control of farm equipment.

Oil and Gas: Controlling fluid flow in oil and gas extraction and transportation.

Food and Beverage Processing: Managing liquid raw materials and cleaning fluid transport.

Aerospace: Used in hydraulic and fuel management systems for flight control.

Paper Industry: Controlling slurry and additives flow to ensure stable production.

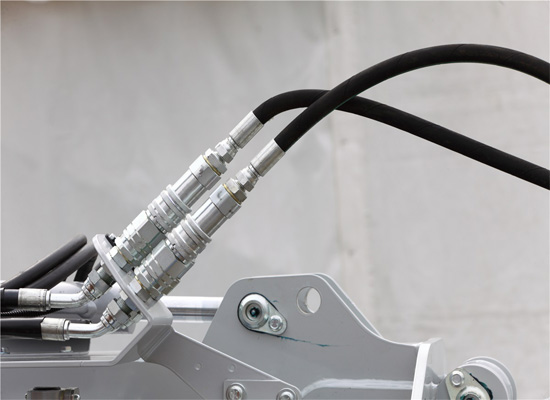

How to Install Hydraulic Quick Hose Fittings and Couplers

How to Install Hydraulic Quick Hose Fittings and Couplers

A Guide to Selecting Hydraulic Quick Fittings and Couplers

A Guide to Selecting Hydraulic Quick Fittings and Couplers

Pneumatic manifold: the silent conductor of the automation system

Pneumatic manifold: the silent conductor of the automation system

1/2 Inch Hydraulic Hose Couplers: Specifications, Installation, and Applications

1/2 Inch Hydraulic Hose Couplers: Specifications, Installation, and Applications

In-depth Analysis of Solenoid Valves: Principles, Structure, and Comprehensive Guide

In-depth Analysis of Solenoid Valves: Principles, Structure, and Comprehensive Guide

You May Interest In

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap