Sep 01, 2025

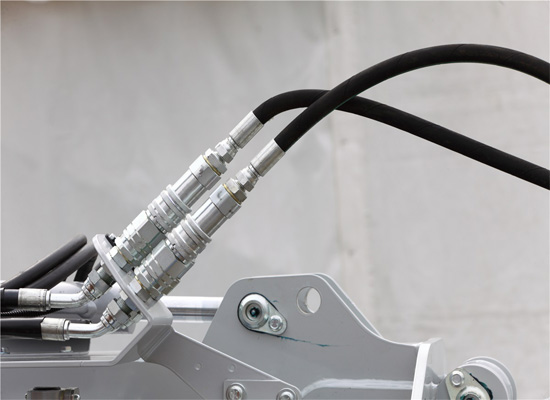

Proper installation of hydraulic hose fittings and quick couplers is directly related to the safety, reliability, and service life of the hydraulic system. It not only ensures efficient transmission of hydraulic fluid between different hydraulic components but also provides good sealing, reducing the risk of hydraulic fluid leakage, saving energy, and protecting the environment.

Although hydraulic quick couplers bring many conveniences to hydraulic systems, improper connections can cause various problems. To avoid unnecessary losses, it is essential to first understand these issues and take proper precautions during installation.

◆ Mismatched coupler and hose connection

If we do not check whether the coupler's model, pressure rating, and hose diameter match before connecting, it may result in the coupler not fitting properly or leaving large gaps, which can easily cause leakage.

◆ Inspection of the seals

If the installation direction of the seal and the functionality of the O-ring are not checked during installation, it can result in hydraulic oil leakage even after the coupler is connected.

◆ Efficiency decreases

If the coupling specification is too small and the internal valve core design has high resistance, it can easily cause clogging by impurities and reduce the operating efficiency of the actuator.

◆ Environmental unsuitability

If the coupling is frequently connected and disconnected in environments with sand, dust, or mud, it will lead to reduced sealing performance and shortened service life.

◆ Difficult to connect or disconnect

If lubrication and inspection of the locking mechanism are neglected for a long time, it may cause wear or deformation of the coupling, as well as sticking of the locking mechanism.

Connecting a hydraulic quick-release coupling is a simple process, but it must be done with care to ensure a secure, leak-free connection and maintain the integrity of the hydraulic system. Below is a step-by-step guide to properly connecting a hydraulic quick-release coupling:

System Preparation: Ensure the system is depressurized. Before making any connections, ensure the hydraulic system is depressurized to avoid any accidental fluid leaks or dangerous pressure buildup. You can do this by shutting off the equipment or activating a pressure relief valve, if available.

Aligning the Coupling: Position the coupling assembly with the male (plug) and female (socket) connectors of the quick-release coupling, ensuring they are correctly oriented for connection. Depending on the coupling type (e.g., ISO, flat-face coupling), ensure the assembly is oriented correctly to avoid cross-threading or misalignment.

Connecting the Coupling: Push the components together: Insert the male (plug) connector into the female (socket) connector. Ensure the connectors are fully inserted and the connector ends are flush.

Checking the Connection: Ensure the connection is secure: Gently pull on the coupling to ensure it is properly locked into place. There should be no play or movement between the male and female couplings.

Testing the Hydraulic System: Starting the System: After the connectors are securely connected, slowly start the hydraulic system to check operation. Monitor the system for any pressure drops or leaks around the connectors.

Safety Check: Verifying No Leaks: After connecting and pressurizing the system, check for leaks at the coupler connections. If leaks are detected, first depressurize the system and inspect the coupler assembly for damage or dirt, which could cause a poor seal.

To learn to how to use a hydraulic quick coupler properly and comprehensively, you also need to know how to disconnect it.

Incorrect disassembly may damage the coupler. You must strictly follow the steps below:

Depressurize the System Again: This is the most critical step. Turn off the equipment and operate the control lever back and forth to release any residual pressure trapped in the lines on both sides of the coupler.

Operate the Locking Mechanism: Firmly grip the outer sleeve of the female coupler.

Pull it fully backward toward the coupler body. This will retract the locking balls and release the male plug.

Separate the Couplers: While keeping the sleeve pulled back, pull the male and female halves apart.

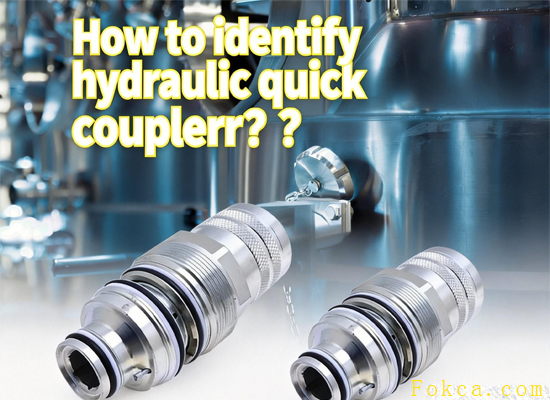

Most hydraulic quick couplers feature a structural design comprising a Male (or Plug) and a Female (or Socket). The Male typically refers to the insertion part with an external locking mechanism, while the Female usually refers to the receiving part with an internal locking mechanism. You can vividly imagine them as the Male being like a plug and the Female being like a socket.

| Component | Male | Female |

| Core Structure | A smooth, shaft-like body with a locking groove or flange at the front. | A sleeve-like structure housing complex locking and valve mechanisms. |

| Locking Mechanism | The passive part. It provides the groove or flange to be locked into. | The active part. Contains a sleeve/latch, steel balls, and a spring. Moving the sleeve engages the balls with the plug's groove. |

| Valve Mechanism | Typically a push rod or valve stem. It pushes open the socket's valve upon connection. | Typically a valve seat and poppet, held closed by a spring to seal when disconnected. |

| Sealing Element | An O-ring on the front, which seals against the socket's inner wall. | A sealing ring on the valve seat or internal body, which seals against the plug's push rod or outer wall. |

| Appearance | Relatively simple structure, with an "insertion" form factor. | More complex structure, often larger, with a "receptacle" form factor. |

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

You May Interest In

Sep 01, 2025 Blog

A Guide to 6 Common Hydraulic Quick Coupler Problems

Nov 23, 2025 Blog

How to identify hydraulic quick coupler?

Nov 25, 2025 Blog

How to replace hydraulic quick coupler?

Nov 26, 2025 Blog

How to use hydraulic quick coupler?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap