- sales@fokca.com info@fokca.com

- WhatsApp: +86 150 5749 1870

Sep 01, 2025

Hydraulic quick fittings and couplers are critical components in a hydraulic system, as they play an essential role in maintaining the safety and efficiency of the system. It is important to understand how to select the correct fitting, since there are many types of hydraulic fittings and couplers available, and finding the most suitable one for your specific application can be challenging.

Hydraulic quick connect fittings can generally be categorized by sealing method, pressure rating, and connection type. Therefore, this article will focus on the common causes of hydraulic quick fitting failures and provide examples of selecting the right types for applications such as bulldozers, harvesters, cutters, and hydraulic jacks.

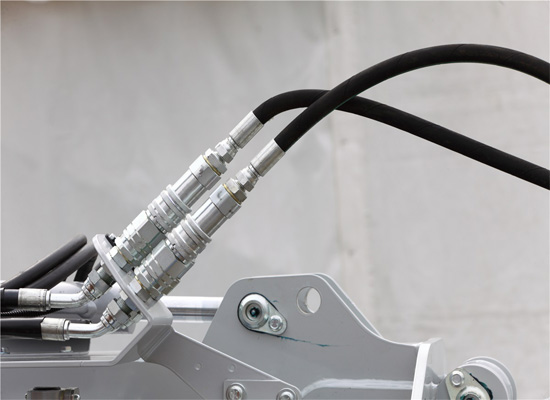

A hydraulic quick coupler is a type of fitting used for the rapid connection and disconnection of hydraulic lines without the need for tools. By automatically opening the valve mechanism during connection and separation,This quick connector can effectively reduce equipment downtime and improve industrial production efficiency. Hydraulic quick connectors generally consist of a male plug and a female plug. When they are connected together, they can form an effective leak-proof connection. The locking mechanism can ensure that the connector is properly connected during use and can be easily unlocked when needed.

Operating Environment: If the industrial environment is high in impurities or dust, it will accelerate the aging of the seals. If the residual pressure is not released when the connector is disconnected, it will easily cause problems such as connector wear and locking mechanism seizure. If the connector is not fully inserted, it may suddenly fall off during operation and cause oil spraying. In addition, the resistance of the valve core should be adapted to the connector to avoid clogging.

Before making any connection, make sure the hydraulic system has been depressurized. This is often overlooked. You need to turn off the equipment or pneumatic pressure relief valve first. When connecting, you need to ensure that the male and female connectors are inserted into the female connector in the correct direction, avoid cross-threading or misalignment, and keep the end faces flush. After inserting the connection, gently pull to check whether the connection is firm and whether there are any pressure changes or media leakage.

Main components and advantages of hydraulic systems

Main components and advantages of hydraulic systems

How to Install Hydraulic Quick Hose Fittings and Couplers

How to Install Hydraulic Quick Hose Fittings and Couplers

A Guide to Selecting Hydraulic Quick Fittings and Couplers

A Guide to Selecting Hydraulic Quick Fittings and Couplers

Pneumatic manifold: the silent conductor of the automation system

Pneumatic manifold: the silent conductor of the automation system

1/2 Inch Hydraulic Hose Couplers: Specifications, Installation, and Applications

1/2 Inch Hydraulic Hose Couplers: Specifications, Installation, and Applications

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap