- sales@fokca.com info@fokca.com

- WhatsApp: +86 150 5749 1870

Aug 27, 2025

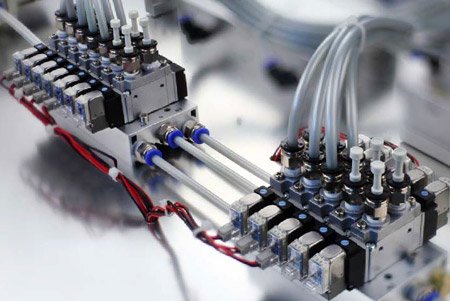

In modern automation systems and industrial machinery, compressed air is a crucial power source. Much like an efficient conductor leading an orchestra, the pneumatic manifold (Air Manifold) silently coordinates every movement of pneumatic components. This article will delve into the world of pneumatic manifolds and explore why they have become an indispensable part of automation design.

A pneumatic manifold, often referred to as a valve manifold, is an integrated modular system that serves as the central hub for distributing and controlling compressed air. Its main body consists of a metal or polymer block with internal channels, one main air inlet, multiple outlets, and several solenoid or pneumatic valves mounted on the body to control the on/off state of each outlet. The air manifold precisely regulates the airflow to various pneumatic actuators.

Imagine a scenario without a manifold: each pneumatic valve would require individual connections to the air source and electrical circuits, resulting in a bulky, cluttered system that is difficult to maintain. Pneumatic manifolds eliminate this chaos through integrated design. However, a limitation of pneumatic manifolds is their high technical complexity, requiring detailed and professional understanding before use.

Pneumatic manifolds are not only useful for integrating power and signal distribution for solenoid valves but also offer the following advantages:

Simplified Installation: Significantly reduces the need for individually installing each valve and numerous independent air tubes and cables, saving time and labor costs.

Space Savings: Compact design allows centralized control of multiple valves in limited spaces, optimizing machine layout.

Improved Reliability: Reduces potential leakage points associated with multiple fittings and connectors, enhancing overall system integrity.

Ease of Maintenance and Troubleshooting: Centralized valve placement makes it easier to detect issues, replace components, or modify the system quickly.

Enhanced Performance: By reducing the air volume between the source and valves, system response speed can be improved.

To use an air manifold correctly and efficiently, it is essential to understand each step of its operation:

Air Supply: Compressed air is supplied from the factory air source to the main inlet of the manifold block.

Internal Distribution: Air is distributed through internal channels to a common chamber, supplying all mounted solenoid valves.

Electrical Signal Control: Electrical signals from a programmable logic controller (PLC) or controller are sent to specific solenoid valve coils.

Spool Actuation: The energized coil generates a magnetic field, driving the spool to move and altering the air path.

Airflow Direction: Depending on the spool design, compressed air is directed to the corresponding outlet to actuate the device, while air from the opposite side is exhausted through the outlet.

Actuator Operation: The controlled air drives the pneumatic actuator to perform mechanical actions.

Pneumatic manifolds can be categorized into two types based on their connection methods:

Multi-Pin Connection Type: This is a traditional and common form. A large multi-pin cable connector is plugged into the manifold to supply power and signals to all solenoid valves. It simplifies wiring but requires connecting each valve's control lines to the corresponding pins.

Bus/Network Connection Type: This is a more modern approach. The manifold integrates a communication module, allowing all valves to be connected, communicated with, and powered via a single network cable. This greatly reduces wiring complexity and enables advanced diagnostics and parameter configuration.

As an integrated application system, every component is critical and requires understanding and maintenance:

Manifold Body: A solid base with precision-machined air channels.

Solenoid Valves: Core control components, typically compliant with ISO 5599/1 or NFPA standards, designed modularly to be stacked like building blocks.

Air Plate: Located between the body and valves, ensuring airtight connections and distributing air to each valve.

Electrical Connector: Multi-pin connector or bus module.

Mounting Accessories: Rails or baseplates for installing the entire assembly in cabinets or machines.

As an integrated system, air manifolds offer the following advantages compared to multiple dispersed individual valves:

Advantages:

Saves space and weight

Simplifies installation and wiring

Reduces leakage points and energy consumption

Facilitates maintenance and troubleshooting

Improves system response speed

Supports modular expansion

Disadvantages:

Higher cost

Steeper learning curve

Higher risk of single-point failure

Installation:

Choose a clean, dry, vibration-free, and easily accessible location.

Ensure the air source is clean and dry, and install a filter regulator lubricator (F.R.L) in the supply line.

Tighten pipe fittings and valve mounting screws to the manufacturer's specified torque, avoiding over-tightening.

Connect electrical components correctly, paying attention to grounding and shielding to prevent electromagnetic interference.

Maintenance:

Regular Inspections: Check for air leakage sounds and external damage.

Keep Components Clean: Maintain cleanliness of all parts.

Filter Drainage: Regularly drain the pre-air filter.

Spare Parts Strategy: Keep common solenoid valves and seal kits as spares for quick replacement.

Pneumatic manifolds are far more than simple connecting blocks. They exemplify the pursuit of efficiency, reliability, and simplicity in modern industrial automation. By integrating dispersed components into an intelligent and efficient whole, they not only optimize machine design but also reduce the total cost of ownership. Whether in simple equipment or complex production lines, pneumatic manifolds are the "silent conductors" ensuring efficient and reliable operation of pneumatic systems, making them an indispensable part of any automation project.If you have any quesition,contact us directly!

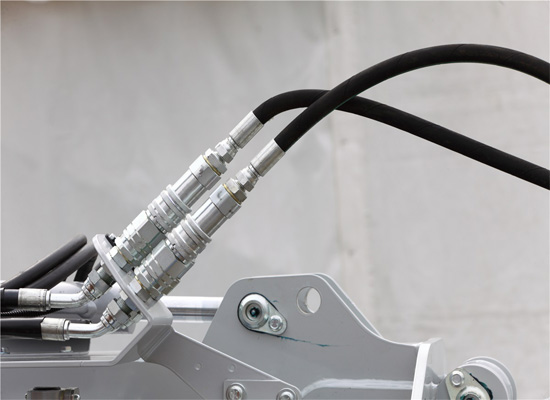

Main components and advantages of hydraulic systems

Main components and advantages of hydraulic systems

How to Install Hydraulic Quick Hose Fittings and Couplers

How to Install Hydraulic Quick Hose Fittings and Couplers

A Guide to Selecting Hydraulic Quick Fittings and Couplers

A Guide to Selecting Hydraulic Quick Fittings and Couplers

Pneumatic manifold: the silent conductor of the automation system

Pneumatic manifold: the silent conductor of the automation system

1/2 Inch Hydraulic Hose Couplers: Specifications, Installation, and Applications

1/2 Inch Hydraulic Hose Couplers: Specifications, Installation, and Applications

You May Interest In

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap