- sales@fokca.com info@fokca.com

- WhatsApp: +86 150 5749 1870

Aug 22, 2025

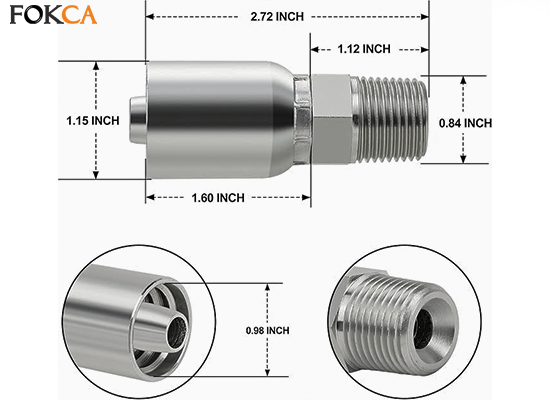

In a sealed hydraulic system, choosing the right hydraulic hose and fittings is a key factor in ensuring efficient fluid transmission and stable operation.1/2 inch hydraulic hose fittings are a type of hydraulic fitting designed to match hoses with an inner diameter of 12.7 mm or 1/2 inch.

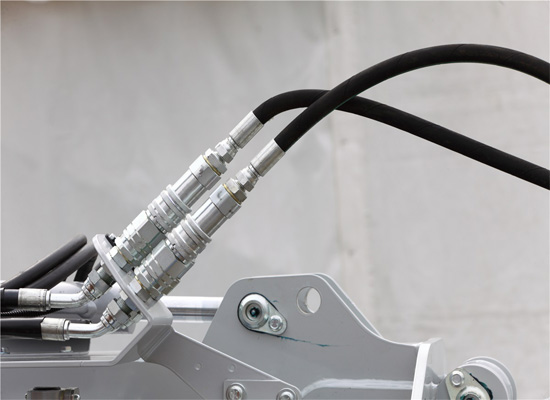

These fittings are widely used in industrial machinery, agricultural equipment, and construction vehicles. Selecting the wrong fitting can lead to leaks, system failures, or downtime, causing additional costs.This article will provide a detailed overview of the most common and widely used 1/2 inch hydraulic hose fittings.

A hydraulic hose fitting is a type of hydraulic accessory that connects hydraulic hoses to other hydraulic components. It plays a crucial role in ensuring efficient fluid transmission and maintaining the system's seal integrity.A 1/2 inch fitting usually refers to a fitting designed to match a hose with a 1/2 inch inner diameter. These hoses typically have a working pressure of 2500–4000 psi, with a burst pressure approximately four times the working pressure. They are made of abrasion- and corrosion-resistant rubber, which protects against external wear and allows the transmission of hydraulic oil, water-based hydraulic fluids, or certain non-corrosive chemical liquids.

Compared to larger-diameter hoses, 1/2 inch hoses and fittings are more flexible, making them suitable for medium-pressure pipeline layouts.

1/2 inch hydraulic hose fittings come in various types, each with a specific structure, application, and function:

Straight fittings – for inline hose connections

Elbow fittings – change the hose direction and prevent bending

Tee fittings – split hydraulic flow into two lines

Swivel fittings – prevent hose twisting

Flange or ORFS fittings – suitable for high-pressure industrial systems

When selecting a fitting, consider hose layout, space limitations, and pressure requirements.

Hydraulic hose fittings are commonly made from the following materials to meet different industry and fluid requirements:

Carbon Steel – high strength, suitable for high-pressure applications, but prone to rust

Stainless Steel – corrosion-resistant, ideal for outdoor or harsh environments

Brass – lightweight and corrosion-resistant, suitable for low-pressure systems

Material selection should consider system pressure, fluid type, and operating environment.

To ensure performance and compatibility, pay attention to these parameters:

Working and burst pressure – the fitting must withstand the system's maximum pressure

Temperature range – suitable for operating temperatures

Connection standards – JIC, NPT, BSP, ORFS

Thread type and size – ensures proper thread engagement and prevents leaks

Hose compatibility – must match the 1/2 inch hose and reinforcement layers

Clean hose ends and fittings before assembly

Avoid over-tightening to prevent thread or seal damage

Use recommended torque during installation

Regularly inspect fittings for wear, corrosion, or leaks

Replace damaged fittings immediately

Determine system pressure type – use carbon steel or stainless steel fittings for high-pressure systems

Select fitting type – choose straight, elbow, tee, or swivel fittings based on hose layout and fluid direction

Check material compatibility – ensure corrosion and chemical resistance, and match hydraulic fluid

Confirm size and standard – verify 1/2 inch diameter and thread type

Consider environmental factors – temperature, vibration, and chemical exposure

If you want to learn more about hydraulic couplers, you can check out our blog articles.

Choose reputable brands or certified suppliers

Identify differences between NPT and BSP thread types

Maintain an inventory of common fittings for quick replacement

Use dust caps during storage to prevent contamination and reduce wear

Choosing the right 1/2 inch hydraulic hose fittings is critical for the reliability, safety, and performance of a hydraulic system. By considering type, material, pressure rating, thread standard, and installation/maintenance, you can effectively prevent leaks, reduce downtime, and extend the life of your hydraulic system.

How to Install Hydraulic Quick Hose Fittings and Couplers

How to Install Hydraulic Quick Hose Fittings and Couplers

A Guide to Selecting Hydraulic Quick Fittings and Couplers

A Guide to Selecting Hydraulic Quick Fittings and Couplers

Pneumatic manifold: the silent conductor of the automation system

Pneumatic manifold: the silent conductor of the automation system

1/2 Inch Hydraulic Hose Couplers: Specifications, Installation, and Applications

1/2 Inch Hydraulic Hose Couplers: Specifications, Installation, and Applications

In-depth Analysis of Solenoid Valves: Principles, Structure, and Comprehensive Guide

In-depth Analysis of Solenoid Valves: Principles, Structure, and Comprehensive Guide

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap