May 14, 2025

In modern industrial manufacturing and automation systems, pneumatic hose and connectors are key components in fluid transmission systems, responsible for the stable, safe, and efficient delivery of media such as hydraulics, pneumatics, and lubrication. They directly influence the operational reliability of equipment, system efficiency, and the sealing and convenience of maintenance.

Pneumatic tubing refers to flexible tubing used to transmit compressed air and serves as the main conduit in pneumatic systems connecting various pneumatic components.

Pneumatic Connectors are connecting and sealing components that securely connect the air hose to pneumatic components include actuator,valves, or another pipe.In a compressed air system, air fittings may be small components, but they play a critical role in ensuring safety, compatibility, and efficiency.

This article will help you better understand the materials and types of pneumatic products hoses and fittings.

Fokca's air hose and tubings are primarily used to transport various fluids under dynamic or space-restricted conditions. They offer excellent flexibility, pressure resistance, and media compatibility. As a professional manufacturer, Fokca provides flexible routing solutions for greater design freedom and hoses with oil resistance, high-temperature tolerance, and abrasion resistance for various industrial environments.

To ensure the flexibility and pliability of the tubing, we mainly use the following materials in the production of pneumatic hoses.

Polyurethane: Flexible, kink-resistant, suitable for automation equipment.

Nylon: High pressure and wear resistance, used in heavy-duty industrial applications.

Polyolefin:This material is lightweight, chemically resistant, highly flexible, operates over a wide temperature range, and is cost-effective, making it suitable for general pneumatic systems.

Fluororesin:This material features excellent chemical resistance, a low friction coefficient, and high temperature and pressure tolerance, making it ideal for high-purity and high-durability pneumatic environments.

Rubber:Rubber materials offer outstanding flexibility and elasticity, as well as excellent resistance to wear, oil, and weathering. They ensure airtight transmission of the medium and absorb vibrations, making them a reliable choice for pneumatic tubing.

PVC: More cost-sensitive options where a balance of performance and budget is required.

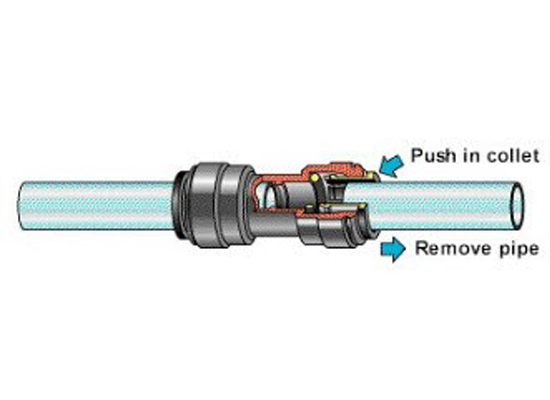

Connectors are responsible for securely linking hoses to different penumatic equipment, valves, cylinder, or other air hose. FOKCA pneumatic fittings ensure excellent sealing performance, safety, and detachability, while also offering convenient connection and installation features such as push-in connection and quick connect and disconnect design.

◆ Fokca's connectors offer the following three advantages:

Wide Compatibility: Available in various common structures, such as threaded, push-to-connect, and flanged types.

Precision Manufacturing: Ensures reliable sealing, prevents leakage, and reduces downtime.

Modular Design: Facilitates quick installation, replacement, and expansion of system configurations.

◆ Based on connection methods, the connectors can be divided into the following types:

Quick Coupling: Plug-and-play; commonly used in scenarios where hoses are frequently changed or moved.

Threaded Fittings: Common types include male/female thread, L-type, T-type, etc., for secure, long-term connections.

Compression fittings, push-in fittings, etc., are suitable for hoses of various types and hardness.

In the industrial field, compressed air systems are widely used in manufacturing equipment, automation tools, spraying systems, and various assembly lines. It is crucial to choose suitable industrial grade air connectors to maintain the stability and efficiency of the air system operation.

As modern industrial and automated manufacturing advances toward higher efficiency, air hose and connectors manufacturers are helping upgrade products in the following three areas:

High-efficiency operation: Ensure that hydraulic/pneumatic systems in robots, machine tools, conveyor lines, and other equipment continue operating efficiently.

Reduced maintenance cost: High-quality hoses and connectors significantly reduce replacement frequency and improve overall equipment lifespan.

Support for smart manufacturing: With the development of Industry 4.0, hoses and connectors must be compatible with sensors and control interfaces to enable pressure/temperature monitoring and early warnings.

Fokca is a professional manufacturer of pneumatic products. If you want to learn more, please browse our product list or Contact us!

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

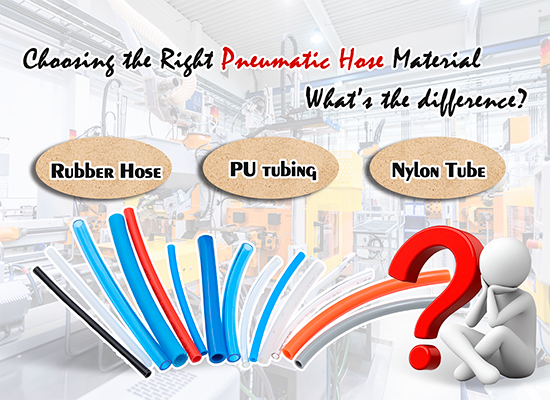

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

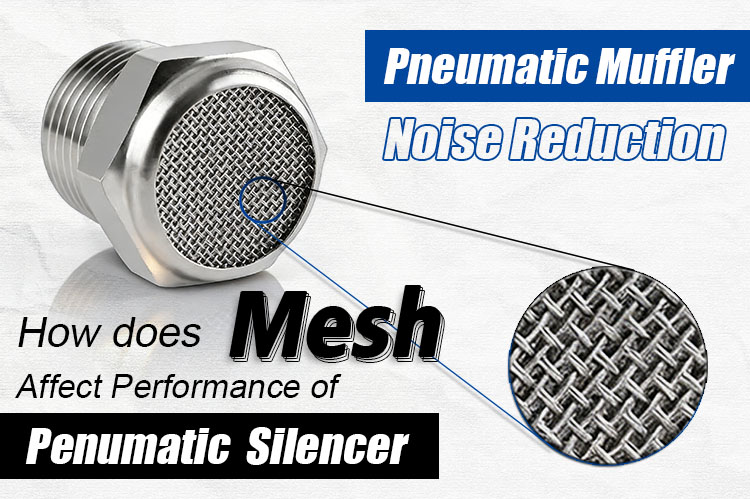

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Nov 18, 2025 Blog

What are the different types of pipe fittings?

Nov 16, 2025 Blog

A Guide to Various Hose and Fitting Connection Types

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap