Dec 12, 2025

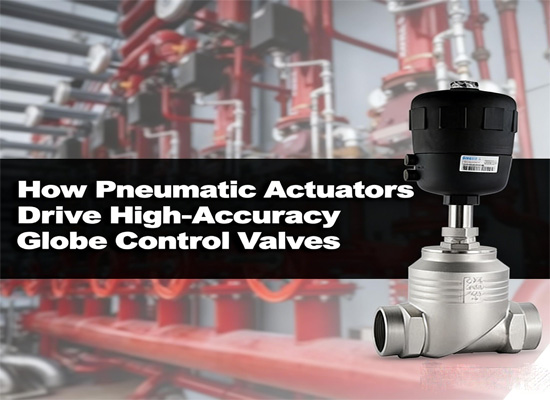

A globe valve is one of the most widely used control valves in industrial automation, especially where accurate throttling and reliable shutoff are required. Its name comes from the early spherical body design, which resembled a globe. Although modern designs vary in shape, the internal flow path still follows the same principle: a linear-moving plug working with a seat to regulate flow precisely. For distributors, equipment engineers, procurement managers and factory owners, understanding how a globe valve works helps ensure correct selection and trouble-free operation in demanding systems.

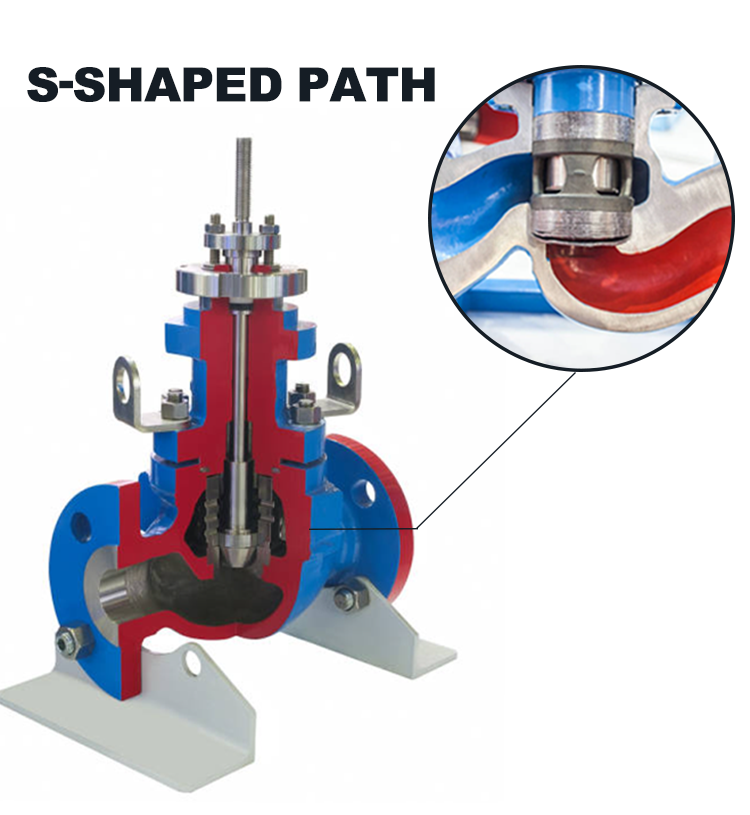

The earliest versions of this valve featured a body shaped like a globe. Inside the cavity, the fluid changed direction through an S-shaped path, creating a stable environment for accurate flow control. The design allowed the plug to move vertically along the stem, offering a precise linear throttling profile rarely matched by other valve types.

Even though today’s pneumatic valve bodies may appear more compact or cylindrical, the working chamber retains the same geometry. This internal shape allows the flow to distribute evenly around the seat, supporting the stable modulation characteristics that engineers rely on in compressed-air systems, steam lines, chemical dosing units and many other industrial processes.

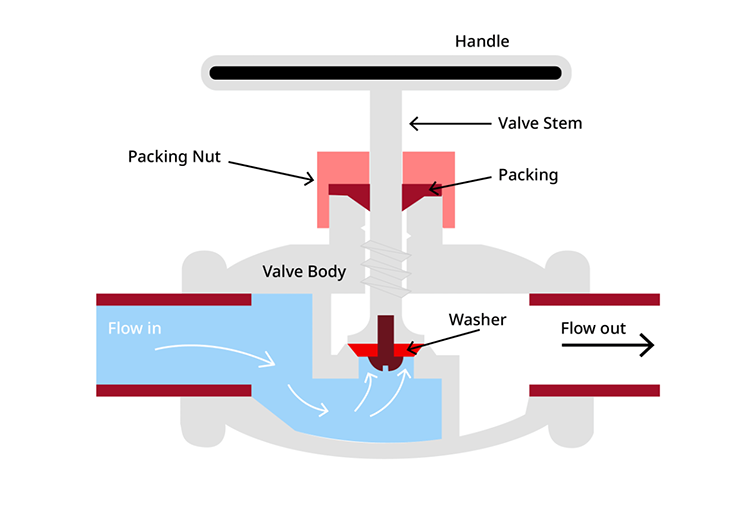

A globe control valve consists of several key components:

◆Valve body with an S-shaped passage

◆Pneumatic actuator or electric actuator

◆Stem guiding linear motion

◆Plug (disc) controlling the opening

◆Seat forming the sealing interface

◆Bonnet housing the stem and packing

◆Packing for shaft sealing

The flow enters beneath the plug, pushes upward, and exits through the opposite side. This arrangement stabilizes the plug during closure, ensuring tight shutoff and lower vibration. Because the pressure direction assists the closing force, the valve becomes unidirectional—its seal is optimized for flow entering from one side. Reversing the direction may reduce sealing integrity, cause plug instability or shorten the packing life.

This is one of the reasons pneumatic control valves in process systems clearly mark the flow direction. When installed correctly, the valve maintains a predictable flow curve and longer service life.

A globe valve regulates flow by adjusting the distance between the plug and seat. When the actuator receives a signal—either from a control system or a pneumatic pilot valve—it pushes the stem downward or lifts it upward. This linear movement provides fine control at low openings and stable regulation at higher flow rates.

For equipment engineers, the biggest advantage lies in the valve’s proportional response. Even small stem movements create measurable flow changes, making the globe valve ideal for applications requiring stable modulation. Whether used with air, steam, water or inert gases, the valve’s predictable performance helps technicians maintain process accuracy and avoid pressure spikes.

When paired with a FOKCA pneumatic actuator, the response becomes faster and smoother. These actuators offer high repeatability and consistent output force, allowing OEMs to integrate them into packaging machines, dryers, conveyors, or chemical dosing equipment.

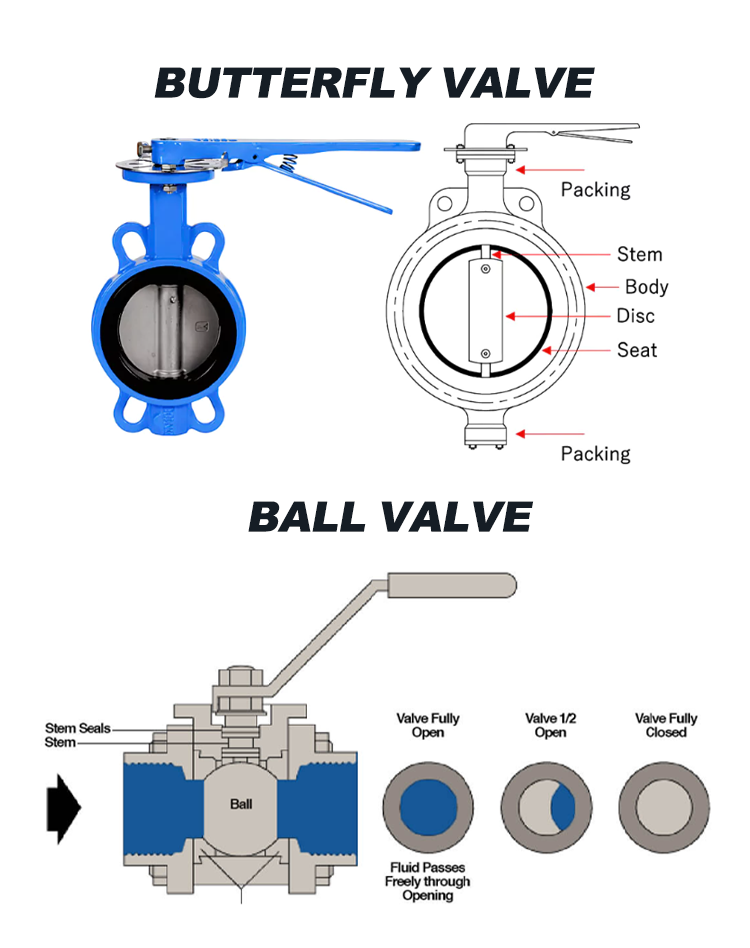

Compared with ball valves or butterfly valves, a globe valve provides superior throttling accuracy. Its structure stabilizes flow even when pressure fluctuates, making it widely adopted in critical loops. The linear flow characteristic allows system designers to predict how each adjustment affects output.

Another advantage is its excellent shutoff capability. The plug presses directly into the seat with uniform force, reducing leakage to extremely low levels. In systems that must prevent reverse flow or contamination—such as food processing, pharmaceutical production or pneumatics used in precise placement systems—this reliability is essential.

Maintenance teams also appreciate its modular construction. Components such as the plug, packing and seat can be serviced without replacing the entire valve. FOKCA’s valve series simplifies this process with standardized parts and durable seals, reducing downtime and total cost of ownership.

Globe control valves appear in industries where accuracy and reliability matter more than maximum flow capacity. Their most common applications include:

◆Process Air and Pneumatic Systems

In pneumatic automation lines, a globe valve provides smooth regulation of compressed air feeding actuators, cylinders and instrumentation. Its stable flow curve prevents sudden pressure surges that may affect motion control.

◆Steam Regulation

Many factories rely on steam for heating, drying or sterilizing. The globe valve’s metal seat and high-temperature tolerance allow precise steam flow control, improving energy efficiency in boilers and heat exchangers.

◆Chemical and Fluid Dosing

Many chemical processes require small yet stable flow adjustments. The linear movement of the plug ensures exact metering, reducing chemical waste and improving batch consistency.

◆HVAC and Building Automation

Globe valves regulate chilled water, hot water and glycol mixtures in HVAC systems. Their predictable flow characteristics help maintain temperature uniformity in large industrial buildings.

◆Vacuum and Low-Pressure Applications

With the correct plug and seat design, globe valves can also regulate low-pressure gases or vacuum lines. This makes them suitable for packaging, semiconductor assembly and delicate pneumatic conveying.

Comparative Performance Table

Valve Type | Flow Control Accuracy | Shutoff Capability | Pressure Drop | Suitable Applications |

Globe Valve | High | High | Medium | Precise regulation, steam, air, chemicals |

Ball Valve | Low–Medium | High | Low | On/Off switching |

Butterfly Valve | Medium | Medium | Very Low | Large pipelines, HVAC |

Diaphragm Valve | Medium | Very High | Medium | Corrosive fluids, ultra-clean processes |

The data clearly shows why the globe valve remains a preferred choice where precision and sealing quality outweigh the need for maximum flow capacity.

FOKCA develops a full range of pneumatic valves and actuated globe valves designed for reliability and high adaptability. For distributors and OEM engineers, FOKCA provides more than standard components—we deliver a solution that elevates system performance.

Key advantages include:

◆OEM/ODM customization for non-standard actuators, special stems, corrosion-resistant seats

◆Precision-machined bodies ensuring stable flow characteristics

◆High-durability pneumatic actuators compatible with globe valve assemblies

◆Interchangeable with major global brands for simplified replacement

◆Full material options including stainless steel, cast steel and bronze

For equipment manufacturers integrating these valves into packaging lines, dryers or process automation equipment, the combination of stable throttling and FOKCA’s strong supply capability ensures predictable system performance and easier global sourcing.

For more information onglobe valves, please do not hesitate to Contact us.

(FK9026)

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Dec 11, 2025 Blog

Two ways for a globe valve to be bidirectional

Dec 10, 2025 Blog

How Does a Manual Globe Control Valve Work?

Dec 08, 2025 Blog

Can a Globe Valve Be Used to Control Steam Pressure

Dec 08, 2025 Blog

How Does a Globe Valve Work

Dec 04, 2025 Blog

How to Identify Gate Valve and Globe ValveLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap