Dec 11, 2025

In modern industrial plants, globe valves remain one of the most trusted devices for accurate flow regulation. As automation continues to reshape manufacturing, the choice between a pneumatic globe valve and amanual globe valve has become a critical decision for engineers, distributors, and procurement managers. The two products share the same flow-control principle but differ significantly in structure, automation level, responsiveness, and long-term operating cost.

FOKCA Automation, as a global supplier of pneumatic components and process-control equipment, provides both pneumatic and manual globe valves, allowing users to configure systems according to the required precision, environment, and budget. The following sections break down the technical differences in a clear, practical way.

A pneumatic globe valve is a flow-regulating valve driven by a compressed-air actuator rather than manual force.

It converts air pressure into linear motion, enabling the valve plug to open, close, or throttle the fluid with high precision.

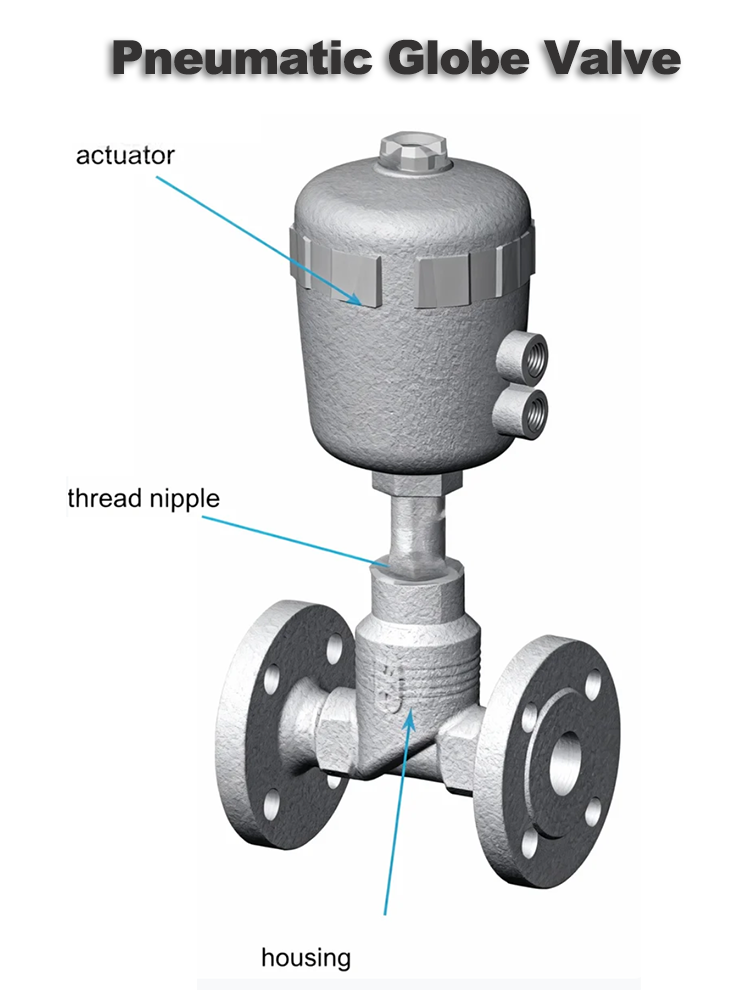

Internal Structure of a Pneumatic Globe Valve

A typical pneumatic globe valve includes:

◆Actuator — diaphragm or piston type that converts air pressure to motion

◆Valve body — typically stainless steel or cast steel

◆Valve stem and plug — controls fluid throttling with stable linear movement

◆Positioner (optional) — ensures accurate percentage control (0–100%)

◆Air ports and spring mechanism — determines fail-open / fail-close function

The actuator sits above the valve body, allowing the valve to respond instantly when receiving air signals from a controller or PLC.

Key Features of a Pneumatic Globe Valve

◆Automated flow control suitable for remote operation and continuous process lines

◆Fast response, ideal for high-frequency cycles

◆Stable throttling with linear or equal-percentage characteristics

◆Supports fail-safe modes, improving plant safety

◆Compatible with harsh or hazardous environments, keeping operators away from danger

◆Minimal manual intervention, reducing operational labor cost

FOKCA’s pneumatic globe valves feature optimized actuator geometry, ISO-standard interfaces, and tight shut-off performance, making them suitable for food processing, pharmaceutical equipment, packaging machinery, and general industrial automation.

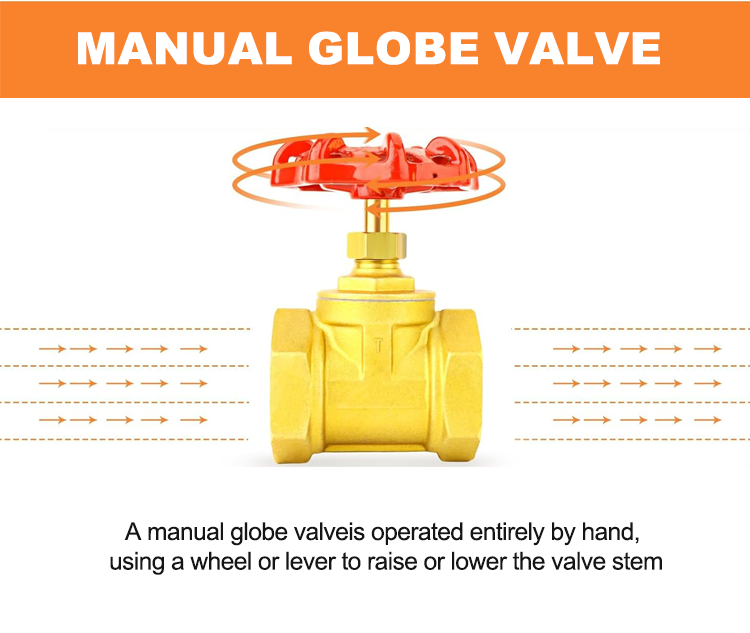

A manual globe valveis operated entirely by hand, using a wheel or lever to raise or lower the valve stem. It maintains the same throttling principle as a pneumatic globe valve but without automation.

Internal Structure of a Manual Globe Valve

A standard manual globe valve includes:

◆Handwheel — manually rotates to control the stem

◆Threaded stem — converts rotational motion into linear movement

◆Valve plug and seat — regulates the flow

◆Bonnet and packing — provides sealing and pressure resistance

◆Cast body — typically bronze, brass, cast iron, or stainless steel

The design is simple, robust, and easy to maintain, making it a staple in general mechanical and utility service lines.

Key Features of a Manual Globe Valve

Simple operation, no air supply required

Lower upfront cost than automated valves

High durability, suitable for infrequent operation

Precise manual throttling at low to medium flow rates

Ideal for smaller systems or where automation is unnecessary

FOKCA also supplies manual globe valves engineered with reinforced sealing materials and precision-machined threads, enabling reliable and repeatable control.

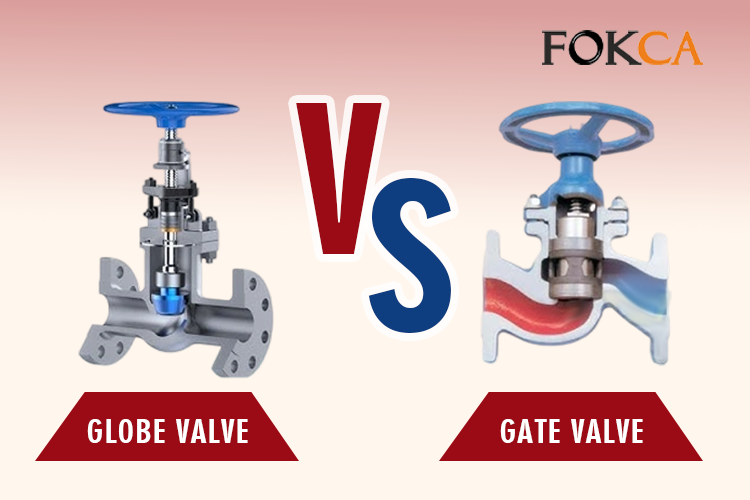

Below is a clear comparison table frequently used by engineers and purchasing teams when selecting the correct valve type.Comparison Table: Pneumatic vs. Manual Globe Valve

Category | Pneumatic Globe Valve | Manual Globe Valve |

Operation Method | Air-actuated, controlled by PLC/automation | Handwheel or lever, manual force |

Automation Level | Fully automated | None |

Response Speed | Fast, ideal for high-frequency cycles | Slow, depends on operator |

Precision | High accuracy with positioner | Medium, operator-dependent |

Safety | Can operate remotely, suitable for hazardous areas | Requires operator presence |

Application Scale | Large systems, continuous processes | Small systems, low-frequency use |

Installation Requirements | Needs air supply & control signal | No external power needed |

Maintenance | Requires actuator service | Very low, mostly mechanical |

Cost Level | Higher initial investment | Lower initial cost |

Best Use Cases | Packaging lines, chemical dosing, steam control, automated equipment | Utility piping, low-pressure systems, occasional adjustments |

1. Frequency of Operation

◆High-frequency switching: pneumatic globe valve

◆Occasional adjustments: manual globe valve

2. Precision Requirements

If your system requires stable and repeatable throttling (e.g., steam regulation, dosing control), pneumatic valves deliver consistent linear control.

3. Safety and Accessibility

In hazardous zones, elevated platforms, or high-temperature lines, pneumatic valves eliminate operator exposure.

4. Budget and Maintenance

Manual valves offer an economical solution for simple, non-critical pipelines. Pneumatic valves, while higher in cost, provide long-term savings through automation efficiency.

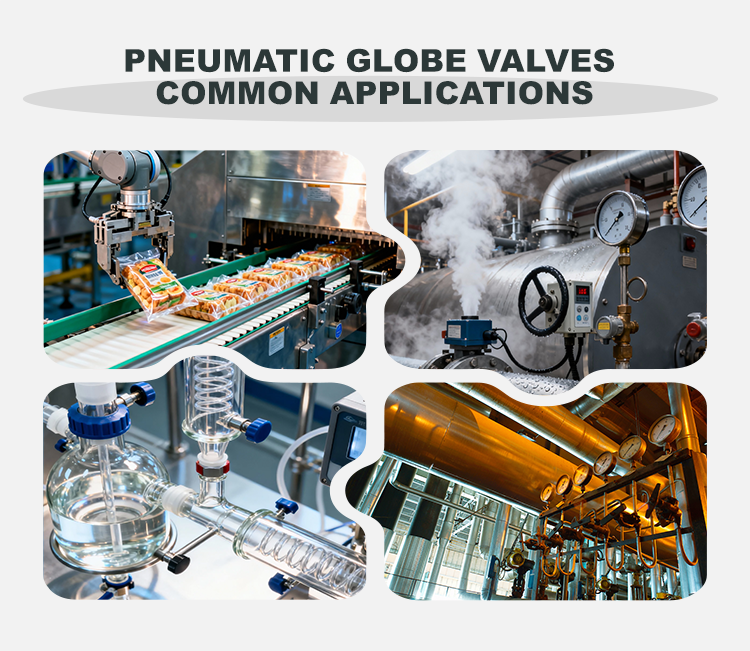

Industries increasingly favor pneumatic globe valves because they integrate smoothly with automated production. Common applications include:

Automated packaging machines

Steam and temperature control systems

Chemical and pharmaceutical dosing

Food-grade fluid control lines

Equipment requiring synchronized movement

FOKCA’s product range supports both automated and manual systems. Key strengths include:

◆OEM/ODM service for customized pneumatic globe valves

◆High-durability actuators compatible with food, packaging, and industrial machinery

◆Stainless-steel and aluminum alloy options for harsh environments

◆ISO-standard actuator interfaces for easy integration

◆Full pneumatic system supply chain, including hoses, connectors, air preparation units, and cylinders

Distributors and equipment manufacturers benefit from a complete, unified source, ensuring compatibility from valve to actuator to pneumatic accessories.

Both pneumatic and manual globe valves serve essential roles in modern fluid-control systems.

The choice depends on automation needs, operating environment, precision expectations, and long-term cost considerations.

For high-efficiency plants aiming for automation, process stability, and worker safety, pneumatic globe valves are the superior option.

For smaller, low-frequency systems, manual globe valves remain a practical and economical choice.

FOKCA Automation supports both directions, supplying and manufacturing components that meet global standards while offering flexible customization for integrators, distributors, and end-users.

If you would like to learn more about pneumatic valve pneumatic push-in fittings, pneumatic tubing, or other air-line components, please feel free to contact us at any time.

(FK9026)

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Dec 12, 2025 Blog

What Is a Globe Control Valve?

Dec 11, 2025 Blog

Two ways for a globe valve to be bidirectional

Dec 10, 2025 Blog

How Does a Manual Globe Control Valve Work?

Dec 08, 2025 Blog

Can a Globe Valve Be Used to Control Steam Pressure

Dec 08, 2025 Blog

How Does a Globe Valve Work

Dec 04, 2025 Blog

How to Identify Gate Valve and Globe ValveLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap