Dec 04, 2025

In fluid control systems, choosing the wrong valve often leads to pressure loss, unstable flow, or even premature failure of pneumatic equipment. In industrial automation and compressed air networks, a small mismatch in valve type can gradually increase energy consumption and reduce system efficiency.Among the most confusing pairs for buyers and engineers are the gate valve and the globe valve.

They may look similar from the outside, but their internal structure, flow path design, and control behavior are entirely different.This difference becomes more obvious in pneumatic control systems, process automation lines, and industrial piping networks, where air pressure stability, response speed, and sealing performance directly affect actuator accuracy and production continuity.

Below, we break down the structure, working principle, performance differences,and selection logic using practical engineering language that fits real pneumatic and industrial applications.

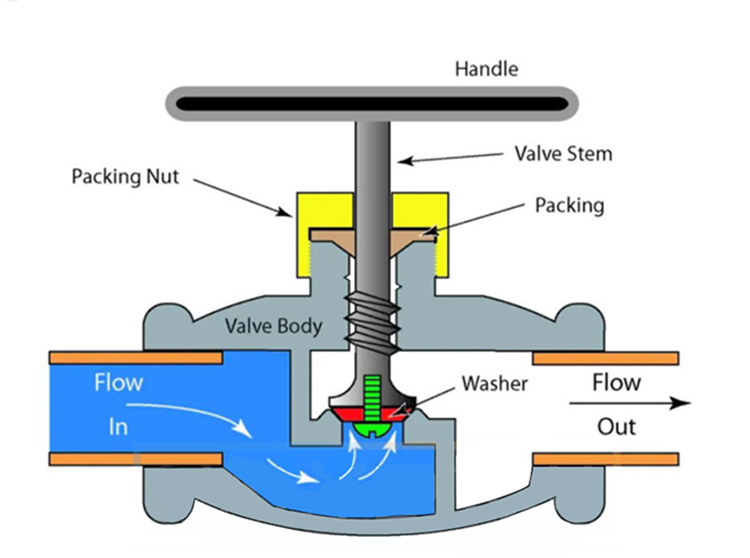

A Globe Valve Pneumatic Globe Control Valve is designed primarily for flow regulation and throttling.

Its internal structure forces the fluid to change direction twice, creating controllable resistance.

Key structural features include:

(1)Disc moves perpendicular to the flow – improves control accuracy

(2)Seat and disc contact area is small – better sealing in frequent operation

(3)Flow direction usually indicated – wrong installation reduces performance

Because of this structure, a globe valve offers excellent control but normally creates higher pressure drop than a gate valve.

Typical Globe Valve Advantage:

◆Stable throttling performance

◆Better leakage control

◆Longer service life in frequent cycling systems

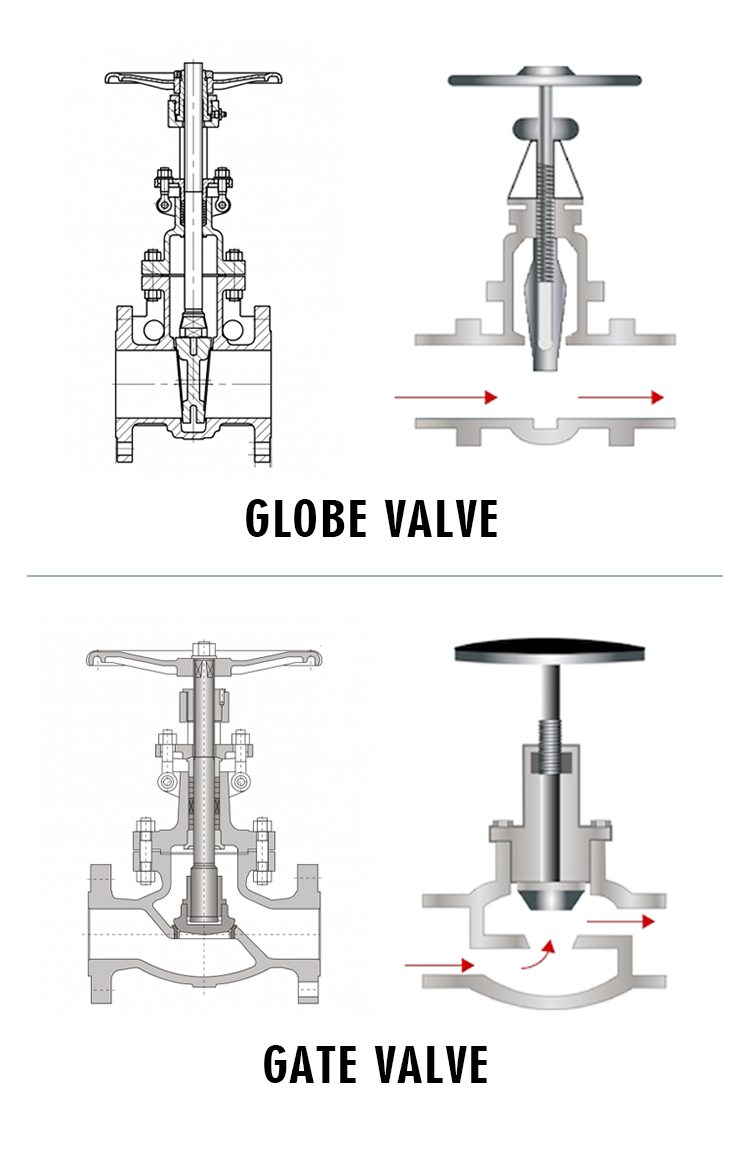

A gate valve is primarily an on-off valve, not a regulation valve.

Its gate moves vertically to block or allow flow, creating a straight flow path when fully open.

That means very low pressure loss, making it perfect for large-diameter pipelines and transport systems.

Its key mechanical traits include:

(1)Straight-through flow passage – minimal turbulence

(2)Large sealing surface area – excellent shut-off capability

(3)Not suitable for throttling – partial opening damages sealing

Typical Gate Valve Advantage:

◆Extremely low pressure drop

◆Ideal for full open / full close

◆Reliable in high-volume pipelines

Feature | Gate Valve | Globe Valve |

Primary Function | Full open / full close | Flow regulation |

Flow Path | Straight through | S-shaped |

Pressure Drop | Very low | Moderate to high |

Control Accuracy | Poor | Excellent |

Installation Direction | Bidirectional | Usually unidirectional |

Actuation Type | Manual / pneumatic | Manual / pneumatic |

Best Used In | Transmission | Control systems |

Engineering insight:

If your system needs stable control, choose globe valve.

If your system prioritizes flow efficiency, choose gate valve.

Choose Gate Valve When:

Large pipe diameter

Need minimum pressure loss

No flow regulation required

Media is relatively clean

Typical industries:

Water treatment, power plant pipelines, oil transportation, firefighting systems.

Choose Globe Valve When:

Flow must be adjusted frequently

Pressure control is critical

High sealing requirement

Pneumatic automation required

Typical industries:

Chemical processing, pharmaceutical plants, compressed air systems, thermal systems.

With the rise of smart factories, Pneumatic Globe Control Valve solutions are widely adopted for automated flow management.

Compared with manual operation, pneumatic actuators offer:

• Faster response

• Better repeatability

• Remote control capability

• Lower labor cost

And in automated processes, globe valves are preferred because they allow linear stable regulation.

Many plants combine them with intelligent air treatment units and PLC control for closed-loop regulation.

FOKCA is a professional supplier specializing in pneumatic and industrial valve systems,

we are not just selling products, but helping partners build long-term market competitiveness through supply stability, quality assurance, and customized solutions.

If your current system experiences:

• Pressure fluctuations

• Excessive leakage

• Unstable flow

• Frequent actuator failure

There is a high chance the valve type selection is incorrect. Many clients reduce maintenance cost by 20–30% simply by choosing the right valve type.

Contact FOKCA for Valve Selection Support.Our team provides model selection, custom engineering, and technical consultation services—helping you turn product choice into system advantage.

If you have any questions about Air Valves ,Pneumatic Components,Hose and fittings feel free to contact us at any time.

Our team is ready to provide you with professional support and the best possible service.

Other websites related to the manufacturing industry:

(FK9026)

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Does Nylon Tubing Become Brittle in Low-Temperature Environments

Does Nylon Tubing Become Brittle in Low-Temperature Environments

You May Interest In

Dec 04, 2025 Blog

How to Identify Gate Valve and Globe Valve

Nov 28, 2025 Blog

Fokca Automaion

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Dec 06, 2025 Blog

How to check pneumatic solenoid valve?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap