Dec 08, 2025

In industrial automation, few components deliver stable flow control as consistently as a globe valve.

Whether the system handles compressed air, steam, water, or chemical media, this valve type remains a preferred choice among distributors, equipment engineers,

and procurement teams who need predictable regulation rather than brute flow capacity.

Its internal structure determines how it performs, why it excels in certain applications, and how a pneumatic valve actuator transforms it into a fully automated control device suitable for modern factory lines.

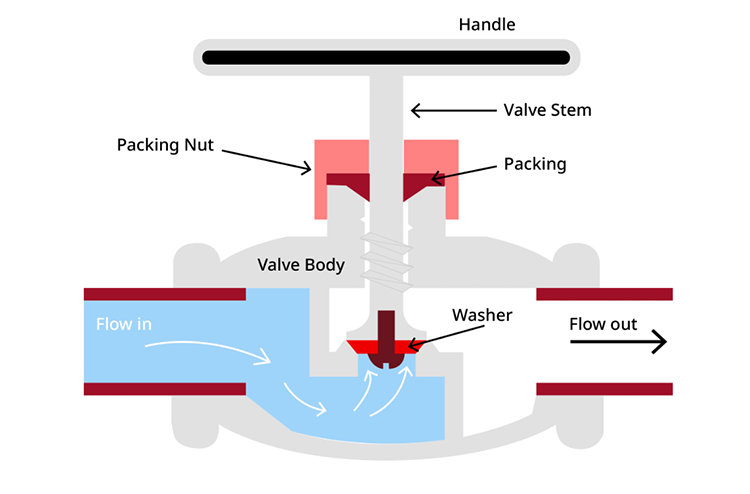

A globe valve is defined by its distinctive S-shaped flow path. Fluid enters the body, changes direction through the seat area, and exits from the opposite side. While this geometry creates resistance,

it also produces highly stable pressure distribution around the valve plug. This stability is the foundation for precise throttling.

The main components—valve body, bonnet, stem, plug, seat, packing, and optionally a pneumatic actuator—work together in a linear vertical motion.

When the stem rises, the plug lifts off the seat, opening the flow channel. When the stem moves downward, the plug presses against the seat, achieving tight shutoff with very low leakage.

In a pneumatic globe valve, compressed air acts on a diaphragm or piston to drive the stem. The design allows fast response, repeatable positioning, and long-term reliability, even in applications with high temperature or corrosive vapors.

Engineers often appreciate how a simple up-and-down stroke can deliver such controllable modulation across the full travel range.

Plants that operate around the clock—such as food processing, pharmaceutical manufacturing, and packaging equipment—prefer the globe valve for several structural advantages.

1. High Accuracy

The valve’s linear flow characteristic means each millimeter of movement corresponds to a measurable change in flow rate. This behavior is vital when maintaining temperature, humidity, or pressure within tight tolerances.

2. Excellent Shutoff Capability

The plug-to-seat contact area produces a reliable seal even under significant differential pressure. Leakage rates are noticeably lower than those of butterfly or ball valves.

3. Versatile Actuator Pairing

Because the stem moves in a straight line, it easily integrates with pneumatic, electric, or manual actuators. With a pneumatic actuator, the valve becomes a robust pneumatic control valve suited to fully automated lines

4. Material Flexibility

Manufacturers can build the valve using stainless steel, cast steel, bronze, or corrosion-resistant alloys. This makes it suitable for water, chemicals, oil, steam, and compressed air.

In several OEM projects, customers have reported improved thermal stability after switching from quarter-turn valves to pneumatic globe valves—pressure fluctuations decreased, reducing quality variations in heat-sensitive processes.

Industry reports also note that properly selected trims can improve controllability by 20–30% compared with general-purpose valves.

Despite its strengths, the globe valve has some limitations engineers must consider before selection. Because of the S-shaped flow path, the valve creates higher pressure drop than straight-through valve types.

For pipelines requiring maximum flow capacity, such as cooling water distribution, other valve configurations are generally preferred.

The second limitation lies in size efficiency. Globe valves are excellent in small and medium pipe diameters, but in very large pipelines the cost and weight increase significantly.

Finally, while a pneumatic valve actuator offers speed and reliability, fluctuations in supply pressure can influence response time. This issue is usually solved by adding a positioner or selecting a larger actuator.

Understanding these limitations helps procurement teams and technicians avoid selecting a valve that performs well in theory but creates unnecessary energy losses in practice.

One of the reasons the globe valve remains popular among distributors and plant operators is its ability to handle both on/off isolation and precise flow regulation.

Below are common industrial uses:

In sterilization and heating lines, globe valves modulate steam to maintain constant temperature.

In mechanical automation, they stabilize compressed air delivery so each station receives consistent pressure.

In chemical dosing systems, their fine control prevents overshoot and pressure shocks that could damage sensitive equipment.

In water treatment, they regulate flow between filtration and circulation stages.

A pneumatic globe valve is especially valuable in applications requiring remote automation. Controlled by PLC signals, it provides repeatable opening adjustments, reducing operator workload and improving system consistency.

For factory managers, this translates into fewer shutdowns, smoother production, and lower maintenance cost.

Different construction styles allow the globe valve to adapt to diverse industrial conditions. Choosing the best type requires understanding how each design affects performance.

Common Types of Globe Valves

Valve Type | Key Features | Typical Use |

Straight-Pattern | Simple structure, easy maintenance | General industrial fluids, compressed air |

Angle-Pattern | 90° flow change, reduces need for elbows | Condensate drainage, corrosive or erosive media |

Y-Pattern | Lower pressure drop, suitable for high pressure | Steam lines, gas control, high-pressure water systems |

Valve trims (plug designs) also influence performance:

Linear trim for proportional control

Equal percentage trim for finer adjustment at low openings

Cage-guided trim for noise reduction and high-pressure environments

When combined with a pneumatic actuator, the valve becomes a stable pneumatic control element for temperature loops, mixing processes, or pressure-reducing stations.

Engineers should also evaluate media type, temperature, pressure, connection method, and maintenance requirements before finalizing a selection.

FOKCA Automation supplies complete pneumatic solutions to global OEMs, distributors, and industrial facilities. Our expertise extends beyond conventional valve supply—our team provides engineering-level support and OEM/ODM customization, ensuring every project receives a fit-for-purpose solution.

Key strengths include:

Custom globe valve assemblies with stainless steel or aluminum options, tailored for steam, compressed air, or chemical processing.

Comprehensive component lineup such as pneumatic cylinders, solenoid valves, angle seat valves, air treatment units, tubing, and fittings.

Strict testing, including leak detection, pressure cycling, and durability checks for long service life.

Flexible OEM production, ideal for distributors who need private-label pneumatic valve ranges.

If you would like to learn more about pneumatic valve pneumatic push-in fittings, pneumatic tubing, or other air-line components, please feel free to contact us at any time.

FOKCA is committed to providing you with the most professional support and service.

Other websites related to manufacturing:

(FK9026)

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

You May Interest In

Dec 08, 2025 Blog

How Does a Globe Valve Work

Dec 04, 2025 Blog

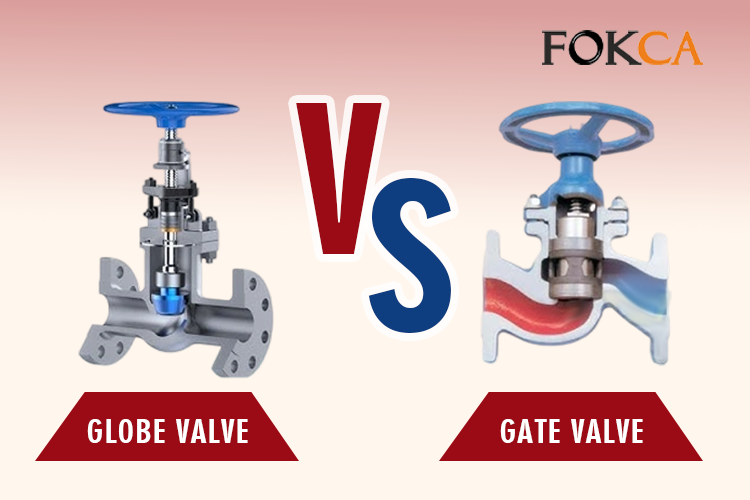

How to Identify Gate Valve and Globe Valve

Nov 28, 2025 Blog

Fokca Automaion

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Dec 06, 2025 Blog

How to check pneumatic solenoid valve?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap