Dec 10, 2025

A manual globe valve is the most commonly used valve for cutting off and regulating fluid flow in pipelines. Its core characteristic is the manual rotation of a handwheel to control the valve's opening, closing, and flow rate adjustment.Its defining feature is its spherical body and a movable disc that operates perpendicular to the flow path—hence the name "globe valve."

By simply rotating the handwheel, operators can precisely adjust the flow rate to the required level. Thanks to its exceptional flow control capabilities, robust design, and ease of maintenance, globe valves are indispensable in a wide range of demanding industrial applications, including water treatment, oil and gas, chemical processing, and power generation.

This comprehensive guide will detail the structural composition, functional roles, key advantages, and essential maintenance practices of manual globe valves.

A manual globe valve achieves reliable shutoff and precise regulation, with its main components as follows:

Valve Body: Typically spherical or "Y"-shaped, featuring an internal curved "S"-shaped flow passage that forces the fluid to change direction. This is the basis for generating high flow resistance and achieving throttling.

Bonnet: Mounted on the upper part of the valve body, forming a pressure-bearing chamber together with the body. It usually contains the stuffing box area.

Disc: The core component responsible for shutoff and regulation. Its bottom sealing surface mates with the valve seat. To optimize regulation performance, the disc is often designed with a V-port, parabolic, or needle shape.

Stem: A precision component connecting the handwheel to the disc. The rotational motion of the handwheel is converted into the vertical linear movement of the disc via the stem’s threads. The stem is commonly designed as either a rising stem or a non-rising stem.

Seat: A fixed annular sealing surface at the center of the valve body’s flow passage, which mates with the disc’s sealing surface to form a tight closure.

Handwheel: The manual operating mechanism. For large-diameter or high-pressure valves, a gearbox is often equipped to reduce operating torque.

Stuffing Box System: Located inside the bonnet and surrounding the stem. It consists of a gland, gland follower, and sealing packing to prevent medium leakage along the stem while allowing smooth stem movement.

Flow Direction Indicator: The valve body usually features an arrow indicating the correct installation direction. Most manual globe valves require "flow under the disc," meaning the medium enters from below the disc. This helps achieve tighter closure and reduces pressure on the stuffing box.

High Regulation Precision: The line-sealing structure of the disc and seat, along with the precision-threaded stem transmission, ensures highly accurate and repeatable opening control, making it particularly suitable for applications requiring fine adjustment.

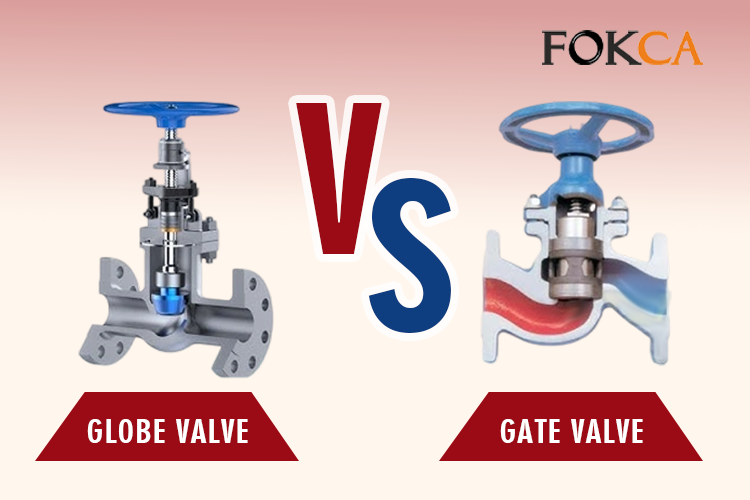

Excellent Shutoff Sealing: The disc is forcibly pressed against the sealing surface during closure, typically providing better sealing than gate valves and reducing the risk of internal leakage.

Robust and Durable Structure: Simple design with strong pressure-bearing capability, suitable for high-temperature and high-pressure conditions.

Easy Maintenance: Most globe valves feature a removable bonnet, facilitating online or offline inspection and replacement of the disc/seat sealing pair and packing.

Intuitive Opening Status: The rising height of the stem directly indicates the valve's opening degree.

Shutoff and Flow Initiation: Achieves reliable closure of the pipeline through complete contact between the disc and the seat, and allows flow by lifting the disc.

Precise Regulation of Flow and Pressure: The primary function of a globe valve. By precisely controlling the opening height of the disc, the annular area of the flow passage is adjusted to achieve fine throttling of the fluid, thereby precisely regulating the system's flow rate and pressure.

Safety Isolation: Provides reliable physical isolation during maintenance or system segmentation, ensuring the safety of upstream or downstream equipment.

Regular maintenance is critical to ensuring valve performance, extending service life, and preventing unexpected failures.

Daily Operation and Inspection: Operate the valve correctly and regularly inspect for external leaks.

Periodic Maintenance: If minor leakage is detected around the stem, the gland follower nuts can be evenly tightened appropriately.

Sealing Surface Inspection: Check the disc and seat sealing surfaces for wear, erosion, or scratches, and replace them if severely damaged.

Thread and Lubrication: Regularly clean the exposed threads of the stem and apply appropriate high-temperature anti-seize compound or lubricant.

Spare Parts Inventory: For valves in critical applications, keep spare parts such as disc/seat sealing pairs, packing, and stems on hand.

(9016)

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

You May Interest In

Dec 11, 2025 Blog

Two ways for a globe valve to be bidirectional

Dec 12, 2025 Blog

What Is a Globe Control Valve?

Dec 08, 2025 Blog

Can a Globe Valve Be Used to Control Steam Pressure

Dec 08, 2025 Blog

How Does a Globe Valve Work

Dec 04, 2025 Blog

How to Identify Gate Valve and Globe ValveLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap