Dec 18, 2025

Pneumatic flow controllers precisely control the airflow velocity entering or leaving a pneumatic actuator. Common flow controllers employ a combination of needle valves and check valves. Needle valves control unidirectional flow, while check valves allow free flow in the opposite direction but prevent backflow. This article will focus on the definition, structure, applications, and usage precautions of flow control valves.

A flow control valve primarily consists of one Core Component,pressure Compensation Mechanism and.

This is the absolute core of any flow valve, determining its basic regulating capability.

Valve Body:The outer shell of the valve, providing the fluid passage and mounting interface.

Valve Seat:A component fixed to the valve body with a precise orifice.

Modible Valve Core:This is crucial for achieving regulation. It moves relative to the valve seat via external operation (such as turning a handwheel).

The gap between the valve core and the valve seat forms a "throttling orifice," which is the passage for fluid to pass through.

When the handwheel is turned, the valve core moves forward or backward in a straight line, continuously and precisely changing the opening area of the throttling orifice.

The opening area directly determines the flow rate. A larger area results in a larger flow rate, and vice versa.

The presence or absence of this component distinguishes ordinary throttle valves from precision flow control valves. Its function is to counteract system pressure fluctuations and achieve flow stability.

Main Components:

Pressure Sensing Element: Typically a flexible diaphragm or a small piston.

Balance Spring: Provides the set reference force.

Compensation Valve Core: An auxiliary valve controlled by the pressure sensing element.

One side of the diaphragm senses the pressure before the orifice, and the other side senses the pressure after the orifice. The difference acts on the diaphragm.

When the inlet pressure increases or the outlet load changes, causing the pressure difference to increase, the diaphragm drives the compensation valve core to automatically close slightly, absorbing the excess pressure. Conversely, when the pressure difference decreases, the compensation valve core opens slightly.

The ultimate goal is to ensure that the pressure difference before and after the orifice remains constant regardless of external changes.

This is an optional integrated module added to meet the very common requirement of "one-way throttling, reverse free flow," forming the most common "one-way throttling valve."

Main components: A valve ball (or valve disc) and a lightly loaded spring, installed in parallel with the throttling passage.

Forward (throttling direction): When fluid attempts to flow in this direction, it pushes the valve ball against the valve seat, closing the one-way valve passage. Fluid can only pass through the adjustable throttling orifice and is throttled.

Reverse (free flow direction): When fluid flows in the opposite direction, the pressure easily pushes the valve ball open, compresses the spring, opens a large passage, allowing fluid to flow freely with almost no obstruction.

Flow control valves are widely used in industrial fields requiring control over speed, synchronization, or smooth movement.

Assembly lines: Controlling the speed of robotic arms and feed cylinders to ensure gentle gripping and precise placement of parts, preventing impact damage.

Welding and cutting: Controlling the travel speed of welding torches or cutting heads to ensure consistent processing quality.

Water treatment: Controlling the flow rate of chemical dosing and sludge discharge.

Food and beverage: Regulating the filling and mixing flow rates of liquid raw materials on the production line.

Flow control valves are one of the five main functions of valves in pneumatic systems, requiring piping and fittings for operation. Combining flow control valves with quick-release valves is a classic and highly efficient technique.

Yes, the core function of a flow control valve is to determine the rate of air entering or exiting the cylinder, thereby precisely regulating its movement speed.

(9016)

You May Interest In

Dec 02, 2025 Blog

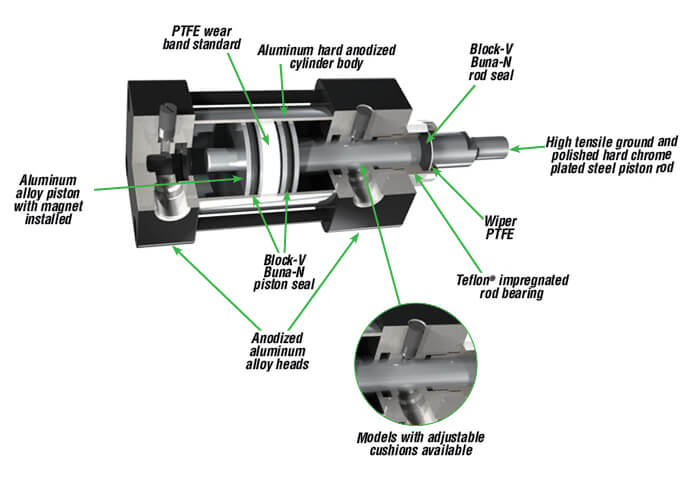

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap