Dec 19, 2025

Pneumatic components are indispensable core parts of modern industrial automation systems, widely used in manufacturing, logistics, robotics, and various automated equipment. They operate using compressed air, achieving mechanical motion and control through cylinders, valves, pipelines, and actuators. Compared with electrical or hydraulic systems, pneumatic systems offer advantages such as simple structure, fast response, easy maintenance, and high safety.

However, during long-term use, pneumatic components may experience performance degradation due to friction, wear, contamination, or insufficient lubrication, potentially leading to system failures that affect production efficiency and equipment lifespan.

Therefore, scientific and standardized maintenance of pneumatic components is particularly important. Maintaining pneumatic components is not only a necessary measure to ensure reliable equipment operation but also a key factor in improving the efficiency and economic benefits of industrial systems.

Manufacturing pneumatic components according to high design specifications and inspection standards can effectively reduce maintenance costs. The following are the requirements for selecting high-quality pneumatic components.

Understand Your System Requirements

Consider pressure, flow, speed, and type of motion required.

Choose the Right Material

Select materials that are corrosion-resistant, capable of withstanding high or low temperatures, and wear-resistant.

Consider Compatibility

Ensure matching between tubing, fittings, valves, and actuators.

Quality and Certification

Choose products from reputable brands that meet standard certifications.

Regular Inspection

Check cylinders, valves, tubing, fittings, and other components for leaks or wear.

Clean and Lubricate

Maintain proper air treatment and lubrication to prevent dust accumulation and friction damage.

Monitor Pressure and Flow

Ensure stable system pressure and avoid overloading.

Replace Worn Parts Promptly

Address minor issues promptly to prevent larger system failures.

Using pneumatic components that do not match the system specifications or are of low quality may lead to leaks and abnormal operation.

During operation, pneumatic systems can accumulate dust, oil, and fine particles, especially in critical components such as valves and cylinders.

It is important to regularly inspect and replace air filters, dryers, and other related devices to maintain clean and dry air.

Operating above the designed pressure or load can accelerate the wear of seals and even cause component damage or safety hazards. It is essential to strictly use the air pressure and load according to the equipment specifications.

Some pneumatic components require proper lubrication. Insufficient lubrication can increase friction and slow down operation, while excessive lubrication or using inappropriate lubricants may contaminate the system or damage seals.

The installation position of pneumatic components, as well as the length and bending of pipelines, can affect airflow efficiency and response speed. Avoid sharp bends, pipeline blockages, or vibration interference, and ensure that all components are securely fixed.

Reiterate the importance of selecting suitable components and performing proper maintenance. Remind that regular inspection and upkeep can extend pneumatic system life and improve efficiency.

(FK9016)

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Why Globe Valve Performs Better in Frequent Opening and Closing Applications

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

Rubber hose vs Polyurethane tubing vs Nylon tubing: Choosing the Right Pneumatic Hose Material

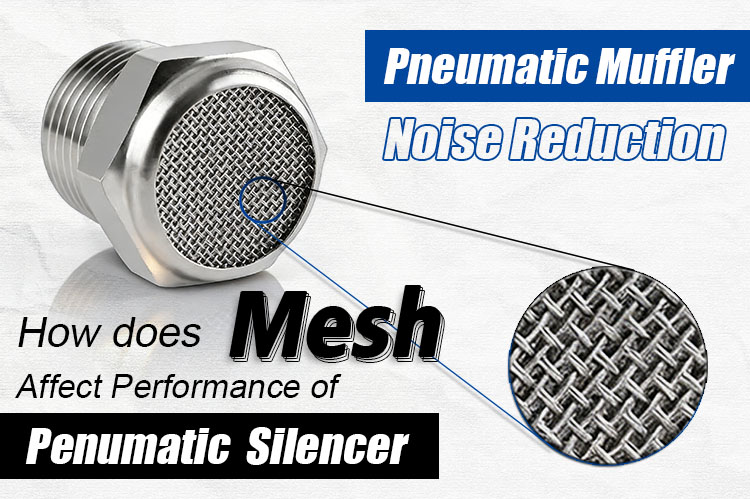

How Does Mesh Affect the Performance of Pneumatic Silencers?

How Does Mesh Affect the Performance of Pneumatic Silencers?

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Hydraulic Quick Couplers: Maintenance Details Most People Overlook

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap