Dec 22, 2025

In industrial automation and machinery, pneumatic systems are widely used due to their simplicity, reliability, and fast response. These systems convert compressed air energy into mechanical motion to perform various tasks such as pushing, pulling, clamping, or rotating.

One of the most fundamental motions in automation is straight line or linear motion, which is essential for operations like lifting, sliding, pressing, or positioning components. Identifying the appropriate pneumatic component for producing this linear motion is critical for system design, efficiency, and performance.

In the pneumatic industry, linear motion is necessary because most industrial actions (such as pushing, pulling, lifting, positioning, and reciprocating) are essentially linear movements. Pneumatic linear actuators can directly and efficiently convert compressed air pressure into stable linear force, featuring a simple structure, low cost, and high reliability. The linear motion of pneumatic cylinders is easy to control and detect, making them well suited for integration with automation systems. With good safety and inherent compliance, pneumatic cylinders are therefore the most core and commonly used actuator type in the pneumatic industry.

A pneumatic cylinder is a pneumatic actuator that converts the energy of compressed air into linear mechanical motion.

When compressed air enters the cylinder through a directional control valve, the air pressure acts on the effective area of the piston. According to the formula:

Output force = Air pressure × Effective piston area

The piston is driven to move linearly back and forth inside the cylinder barrel, thereby causing the piston rod to extend or retract.The direction of motion is controlled by directional control valves, and the movement speed is regulated by flow control valves, enabling the cylinder to achieve stable and controllable linear motion.

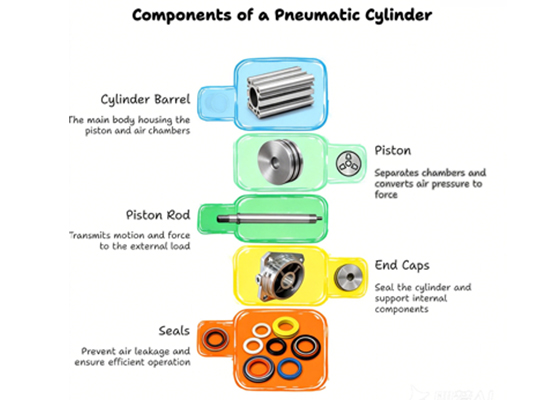

A pneumatic cylinder is mainly composed of the following basic components, which work together to achieve linear motion:

Cylinder Barrel (Tube)

The main body of the cylinder that houses the piston and compressed air. It provides a sealed chamber for the piston to move linearly.

Piston

Located inside the cylinder barrel, the piston separates the chambers and converts air pressure into mechanical force.

Piston Rod

Connected to the piston, it transmits the straight linear motion and force from the piston to the external load.

End Caps (Front and Rear Covers)

Mounted at both ends of the cylinder barrel, they seal the cylinder and support the piston rod and internal components.

Seals

Installed on the piston and piston rod to prevent air leakage and ensure efficient operation.

Cushioning Mechanism (Optional)

Used to absorb impact and reduce noise at the end of the stroke, improving service life.

Air Ports

Openings that allow compressed air to enter and exit the cylinder chambers.

A pneumatic cylinder is a pneumatic actuator that converts the energy of compressed air into linear mechanical motion. Its working principle is that compressed air drives the piston to move back and forth linearly inside the cylinder barrel, thereby causing the piston rod to extend or retract. The following are several types of pneumatic linear actuators.

Motion Type:

The piston moves linearly inside the cylinder barrel, and the force and displacement are transmitted through the piston rod.

Characteristics:

Simple structure and high reliability

High level of standardization

Low cost and easy maintenance

Stroke length is limited by piston rod stability

Typical Applications:

Pushing, pulling, clamping, ejecting, lifting, and other basic motions

Linear Motion Principle:

In a rodless cylinder, the piston moves linearly inside the cylinder barrel. Through magnetic coupling or mechanical linkage, the internal piston motion is transferred to an external carriage, achieving linear displacement without the use of a piston rod.

Main Characteristics:

No protruding piston rod, saving installation space

Capable of long-stroke linear motion

Even force distribution with no risk of rod bending

Smooth operation, suitable for horizontal motion

Typical Applications:

Material handling, transfer systems, linear conveying, pick-and-place applications

Motion Type:

Based on a standard cylinder, guide rods or guide blocks are added to provide additional guidance and support while the piston moves linearly.

Characteristics:

High resistance to side loads and torque

Stable motion with high positioning accuracy

Prevents piston rod rotation

Suitable for carrying eccentric loads

Typical Applications:

Precision assembly, press-fitting, positioning, and alignment processes.

(FK9016)

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Coil Overheating on Continuous Duty of 2-Way Solenoid Valve

Influence of Coil Overheating on Continuous Duty of 2-Way Solenoid Valve

PVC Flexible Tubing vs PU Tubing: Cost Difference Analysis in Equipment Internal Routing

PVC Flexible Tubing vs PU Tubing: Cost Difference Analysis in Equipment Internal Routing

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

You May Interest In

May 06, 2025 Blog

A Complete Guide to Pneumatic ComponentsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap