Feb 10, 2026

In equipment internal routing, selecting the right hose directly affects system stability and total ownership cost. PVC Flexible Tubing and PU tubing are the two most common options used in automation, fluid transfer, and light pneumatic systems. Although both appear similar, their performance in price, wear resistance, transparency, flexibility, and service life differs significantly. Understanding these differences helps distributors, engineers, and purchasing managers make a more cost-effective selection rather than simply choosing by habit.

Polyvinyl Chloride Tubing is produced from mature raw materials with high market availability, resulting in a lower base price. PU tubing, made from polyurethane elastomer, involves more complex polymerization and processing, so the unit cost is usually 1.8–2.5 times that of PVC.

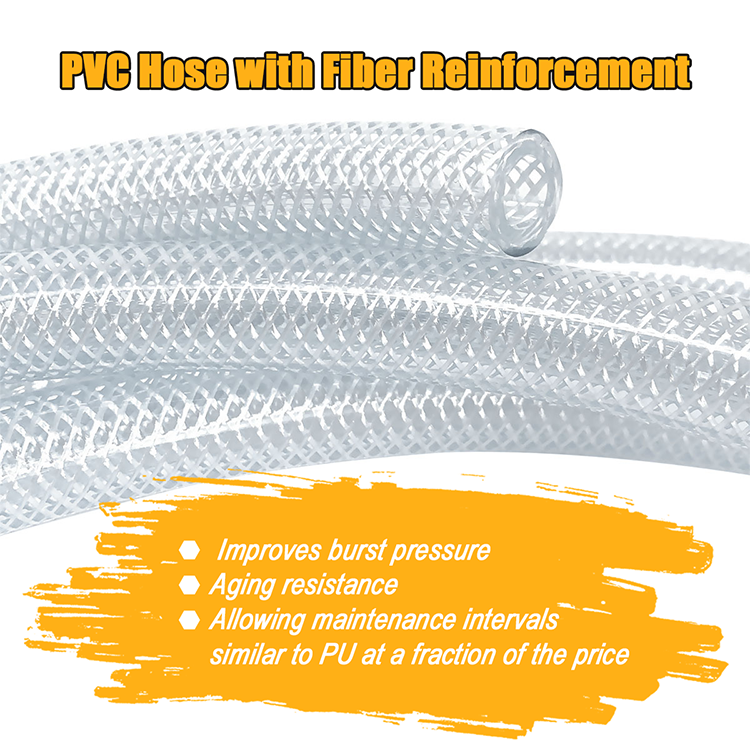

◆PVC Fiber Reinforced Hose further reduces deformation risk while keeping economical pricing.

◆PU offers higher tensile strength but at a clearly higher procurement budget.

For equipment with long internal lines or large consumption, PVC solutions often deliver the best ROI.

PU tubing is recognized for excellent abrasion resistance and performs well in dynamic robotic arms or drag chains. However, in most static internal routing, PVC Hose with Fiber Reinforcement already meets mechanical requirements.

Conclusion: For non-continuous friction environments, PVC provides sufficient durability with lower cost, while PU is only necessary for high-wear motion modules.

Transparency is crucial for visual inspection of bubbles and contamination.

◆Fiber-Braided PVC Hose maintains good clarity even after long use.

◆PU tends to yellow slightly under UV and oil vapor.

Therefore, for medical devices, beverage equipment, and laboratory instruments where visual control matters, PVC Flexible Tubing offers better practical visibility.

PVC has a softer touch and smaller bending radius at room temperature, making installation inside compact cabinets easier. PU becomes stiffer in cold environments.

Engineers report that PVC tubing reduces assembly time and connector stress, especially in small-diameter 4–8 mm lines. For complex routing, this advantage translates into lower labor cost.

PU generally has longer life under high pressure and oil exposure, yet many devices operate below 8 bar and 40°C. In these conditions, Polyvinyl Chloride Tubing already reaches 3–5 years without aging issues.

Using premium grades such as PVC Fiber Reinforced Hose further improves burst pressure and aging resistance, allowing maintenance intervals similar to PU at a fraction of the price.

| Scenario | Recommended Type | Reason |

|---|---|---|

| Static internal air/water lines | PVC Flexible Tubing | Lowest cost, easy installation |

| Long distance with pressure fluctuation | PVC Fiber Reinforced Hose | Better dimensional stability |

| Robotic dynamic motion | PU Tubing | Superior abrasion resistance |

| Food & beverage visual control | Fiber-Braided PVC Hose | High transparency |

| Budget-sensitive OEM equipment | Polyvinyl Chloride Tubing | Best overall economics |

1.Define real working conditions instead of “over-specifying.”

2.For 70% of general equipment, PVC Hose with Fiber Reinforcement is fully adequate.

3.Reserve PU only for dynamic friction, high oil, or extreme temperature.

4.Evaluate total cost: material + installation + replacement frequency.

For most internal routing applications, PVC Flexible Tubing delivers the optimal balance between performance and price. PU remains a premium option for special motion modules, but replacing PVC with PU without clear technical need will increase equipment cost with limited benefit. Distributors and procurement teams should build dual product lines: standard PVC for volume projects and PU for niche high-wear scenarios, ensuring competitiveness and customer satisfaction.

(FK9026)

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Coil Overheating on Continuous Duty of 2-Way Solenoid Valve

Influence of Coil Overheating on Continuous Duty of 2-Way Solenoid Valve

PVC Flexible Tubing vs PU Tubing: Cost Difference Analysis in Equipment Internal Routing

PVC Flexible Tubing vs PU Tubing: Cost Difference Analysis in Equipment Internal Routing

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap