Jan 15, 2026

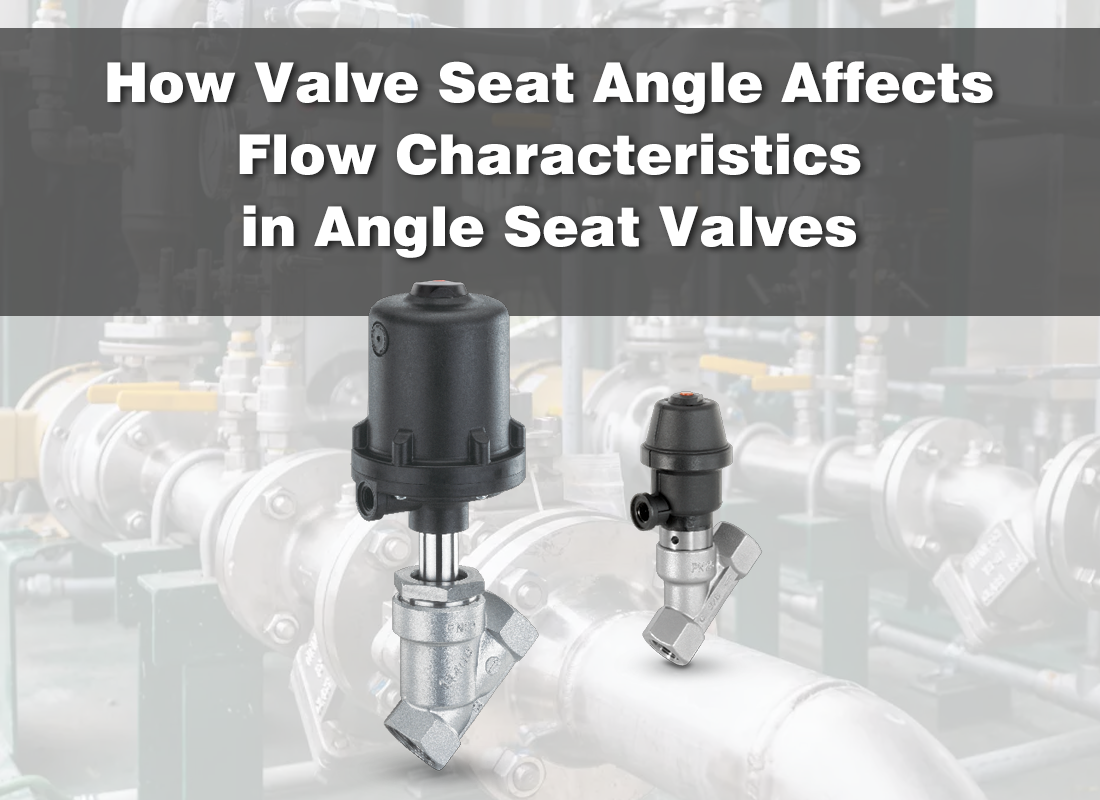

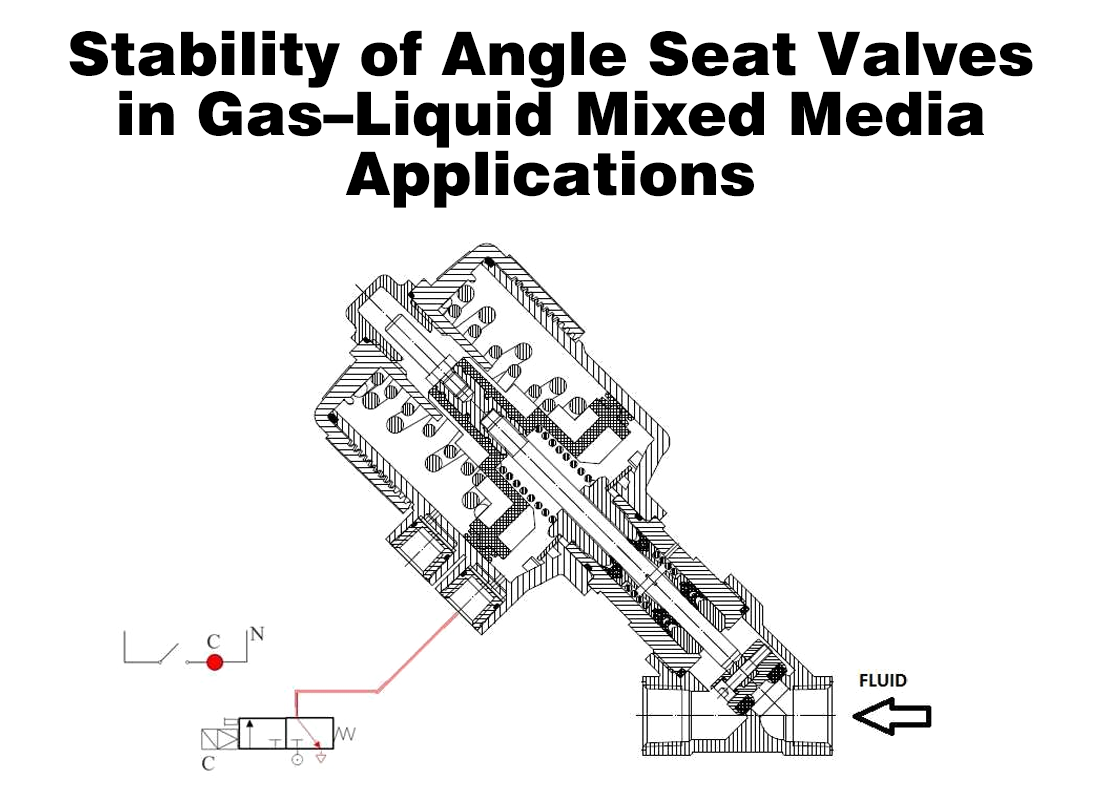

In industrial piping systems, valve size alone does not determine flow capacity. Many engineers encounter situations where a valve with sufficient nominal diameter still causes excessive pressure loss. One of the key reasons angle seat valves perform well in steam, water, and compressed air systems lies in the valve seat angle design, which directly influences flow direction and effective flow area.

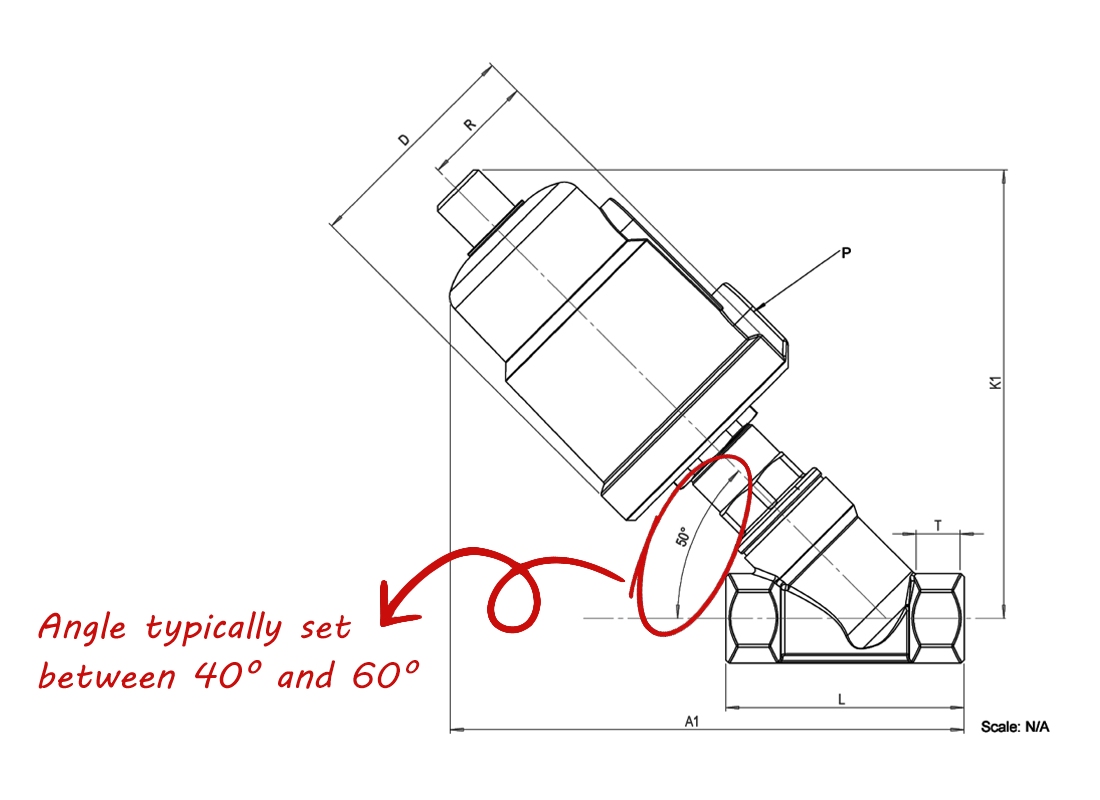

The defining feature of an angle seat valve is the inclined valve seat, typically set between 40° and 60° relative to the pipeline axis. This angle is carefully designed to guide the fluid smoothly through the valve once the plug lifts.

Instead of forcing the medium to strike the seat vertically, the angled structure redirects the flow gradually. This reduces local velocity peaks and limits turbulence, helping maintain a more stable flow pattern.

With the same nominal size, an angle seat valve usually provides a larger effective flow area. When the valve opens, the medium passes through an inclined opening rather than a narrow vertical passage.

From an engineering standpoint, this means that even at partial stroke, the valve can deliver relatively high flow. This makes angle seat valves especially suitable for applications requiring frequent operation while maintaining low pressure loss.

Pressure drop is often caused by sudden changes in flow direction or sharp restrictions inside the valve. The angled seat design distributes pressure loss along a smoother flow path, reducing energy dissipation per unit length.

In steam and compressed air systems, lower pressure drop translates into reduced supply pressure requirements, lower energy consumption, and less stress on upstream equipment.

Structurally, angle seat valves sit between globe valves and ball valves. Ball valves provide excellent flow capacity when fully open but are less suitable for frequent cycling. Globe valves offer stable control but with higher pressure loss. Angle seat valves balance these factors through optimized seat geometry.

| Valve Type | Effective Flow Area | Pressure Drop | Typical Application |

|---|---|---|---|

| Angle Seat Valve | Large | Low | Steam, air, water systems |

| Globe Valve | Medium | Medium–High | Precise flow control |

| Ball Valve | Very large (fully open) | Very low | On/off service |

Angle seat valves are widely used in high-flow, low-pressure-loss applications such as steam distribution lines, cleaning systems, and automated machinery. The seat angle allows engineers to achieve required flow rates without oversizing the valve, helping control system cost and layout complexity.

While the seat angle improves flow performance, larger angles are not always better. Excessive angles may increase valve size, while smaller angles reduce the low-pressure-drop advantage. Well-designed angle seat valves strike a proven balance, making it essential to match the valve specification to real operating conditions rather than focusing on size alone.

(FK9025)

Impact of Trapped Media in the Valve Cavity on Restart Performance of Pneumatic Ball Valves

Impact of Trapped Media in the Valve Cavity on Restart Performance of Pneumatic Ball Valves

Wear Path Analysis of Pneumatic Ball Valve Under Frequent Cycling Conditions

Wear Path Analysis of Pneumatic Ball Valve Under Frequent Cycling Conditions

Mini Push In Fittings: Aging Problems of Plastic Bodies in Humid Environments

Mini Push In Fittings: Aging Problems of Plastic Bodies in Humid Environments

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

You May Interest In

Nov 13, 2025 Blog

What are pneumatic angle seat valves used for?

Nov 13, 2025 Blog

How to check valve seat angle?

Apr 18, 2025 Blog

What is an Angle Seat Valve?

Dec 12, 2025 Blog

What Is a Globe Control Valve?

Dec 11, 2025 Blog

Two ways for a globe valve to be bidirectional

Dec 10, 2025 Blog

How Does a Manual Globe Control Valve Work?

Dec 09, 2025 Blog

Working Principle of Check Valves

Dec 08, 2025 Blog

Can a Globe Valve Be Used to Control Steam Pressure

Dec 08, 2025 Blog

How Does a Globe Valve Work

Dec 04, 2025 Blog

How to Identify Gate Valve and Globe Valve

Dec 04, 2025 Blog

How does a single solenoid valve work?

Dec 03, 2025 Blog

What is double acting solenoid valve?

Dec 02, 2025 Blog

How to clean a pneumatic solenoid valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap