Dec 09, 2025

Check valves are widely used in various fields to control the flow of gas or liquid through different mechanisms. Vacuum systems and small-diameter low-pressure systems typically use diaphragm check valves to prevent backflow and the risks associated with it. This article will discuss the types of diaphragm check valves and their working principles.

A check valve, also known as a one-way valve, allows liquid or gas to flow in one direction while preventing backflow in the system. Unnecessary backflow can lead to malfunctions, leaks, or contamination.

In a diaphragm check valve, a self-centering valve disc or a flexible rubber diaphragm prevents backflow. When the inlet pressure increases, the diaphragm check valve opens, allowing the internal substances to flow through.

There are two main types of diaphragm check valves:

Flexible diaphragm check valves have two default states: the default open type uses a free-floating diaphragm that opens naturally when there is no pressure, requiring almost no opening pressure; the default closed type uses a fixed diaphragm that remains sealed when there is no pressure and requires inlet pressure to open. Both types are suitable for low-pressure check applications, the difference being that the former allows for easier flow, while the latter provides a stronger seal.

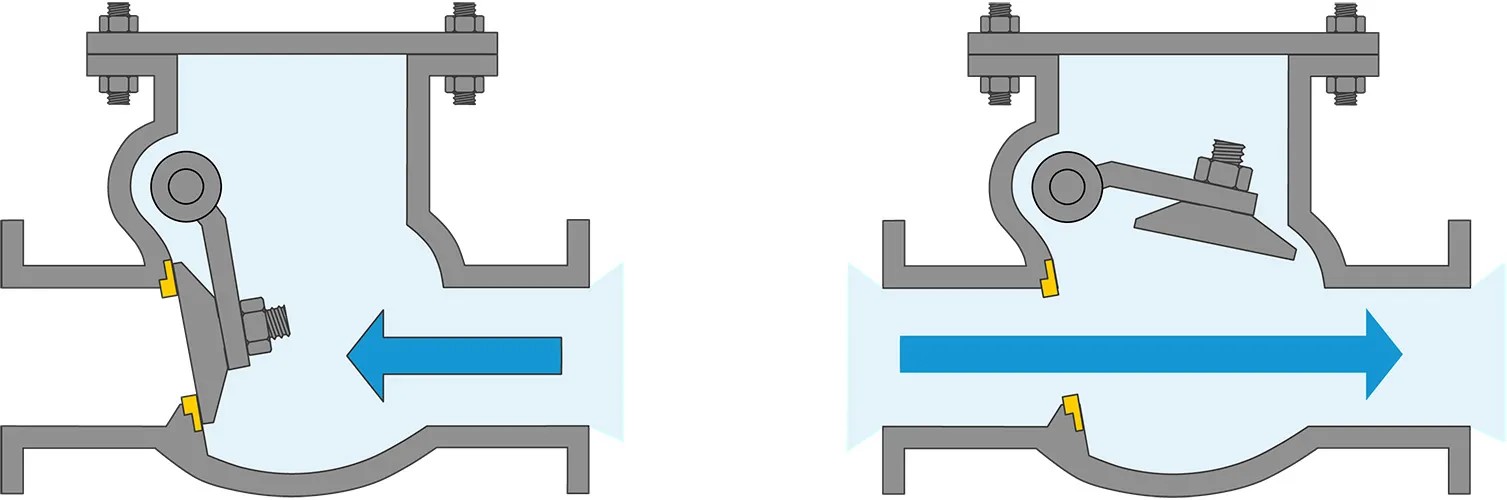

The opening and closing of a check valve rely entirely on fluid pressure and mechanical action, without the need for electrical or pneumatic control. There are generally the following two types of operation.

These diaphragm check valves are typically always open, and their main functional element is a resilient, self-centering elastomer disc. The valve body helps the disc to automatically center itself on or within the valve seat surface.

The valve's sealing surface is located on the inlet side of the valve body, with a smooth, arc-shaped or concave surface and a small central orifice. In the event of backflow, the disc covers the sealing surface, effectively sealing the central orifice. Once the valve is closed, it prevents any backflow of substances.

On the outlet side of these check valves, there is usually a double-layered valve seat with a specific internal channel. When fluid flows forward towards the outlet, the disc presses against the valve seat. The fluid then bypasses the disc and flows through the channel, eventually exiting from the outlet.

Unlike free-floating diaphragm check valves, this type of diaphragm check valve is typically closed and uses a hinged or pleated diaphragm. Positive pressure within the valve allows fluid to flow downstream or forward, thus exerting pressure on the diaphragm.

The pressure that opens the valve is called the opening pressure, which is the minimum pressure sufficient to allow a small amount of gas or liquid to pass through. When the pressure is high enough, the diaphragm opens, allowing the medium to pass through.

A decrease in flow rate creates a pressure differential decrease within the valve. Once the pressure drops to a certain level, it eventually causes the diaphragm to close.

Both types of compact check valves provide stable, automatic flow control and are suitable for a wide range of low-pressure and vacuum applications. A variety of materials are available for the valve body and diaphragm to ensure compatibility with specific chemicals or other media. Furthermore, these valves are highly adaptable when used with compatible protective filters.

Recommended websites for related pneumatic products:

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap