Jan 13, 2026

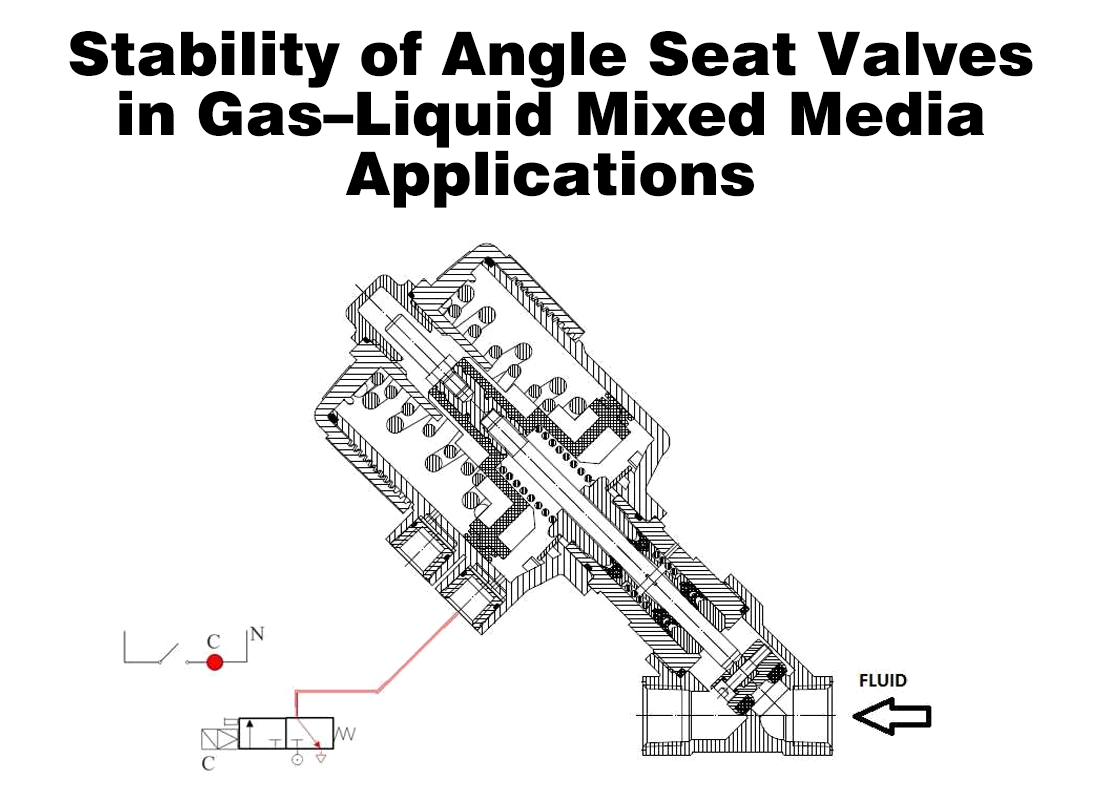

In real industrial systems, fluids passing through valves are rarely ideal single-phase media. Condensate in steam lines, moisture carried by compressed air, or alternating gas–liquid flow during cleaning processes all create gas–liquid mixed media conditions. Under these conditions, differences in valve stability become far more noticeable.

Unlike single-phase flow, gas–liquid mixtures create unstable internal flow patterns. Liquids have higher density and inertia, while gases compress and accelerate more easily. When passing through throttling areas, the interaction between phases generates pressure fluctuations and velocity differences.

These fluctuations apply cyclic forces to the valve trim and seat, often resulting in vibration or noise. Over time, unstable loading accelerates wear on sealing surfaces and can shorten the service life of both the valve and actuator.

Ball valves and gate valves are commonly used, but their structural characteristics make them less tolerant of mixed-phase flow. Ball valves tend to concentrate flow around the ball port at partial openings, where gas–liquid separation causes localized turbulence and noise.

Gate valves rely on vertical gate movement, and uneven flow forces in mixed media can lead to oscillation of the gate. In high-frequency or continuous modulation applications, these effects are amplified.

The stability of an angle seat valve starts with its smooth flow path. Media enters from beneath the seat and changes direction gradually, minimizing sharp contractions and reducing turbulence. This flow geometry helps stabilize gas–liquid mixtures.

Equally important is the linear motion of the valve stem. The valve plug moves axially, and forces generated by mixed media are distributed symmetrically along the stem axis. This reduces lateral vibration and prevents unstable oscillation.

Noise in mixed media applications typically originates from internal flow instability rather than actuator motion. In angle seat valves, the plug design allows fluid to flow evenly around the seat once open, creating a balanced pressure field.

As a result, operating noise is smoother and less aggressive, especially in applications involving wet steam or compressed air with condensate. This contributes to improved system reliability and operator comfort.

Many automated systems involve frequent switching between gas and liquid states, such as filling, flushing, or purging processes. Angle seat valves respond quickly while maintaining stable motion, making them well suited for high-cycle operation.

For engineers, this translates into fewer unexpected failures and reduced maintenance. For distributors and end users, it means predictable performance and lower total cost of ownership.

While angle seat valves perform well in gas–liquid mixed media, proper selection remains essential. Valve body material, sealing design, and actuator sizing must match temperature, pressure, and chemical exposure.

From a structural stability perspective, however, angle seat valves consistently demonstrate superior behavior in mixed media environments, which explains their widespread use in food processing, chemical systems, and automated equipment.

(FK9025)

Impact of Trapped Media in the Valve Cavity on Restart Performance of Pneumatic Ball Valves

Impact of Trapped Media in the Valve Cavity on Restart Performance of Pneumatic Ball Valves

Wear Path Analysis of Pneumatic Ball Valve Under Frequent Cycling Conditions

Wear Path Analysis of Pneumatic Ball Valve Under Frequent Cycling Conditions

Mini Push In Fittings: Aging Problems of Plastic Bodies in Humid Environments

Mini Push In Fittings: Aging Problems of Plastic Bodies in Humid Environments

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Mini Type Pneumatic Push In Fittings: Flow Difference Between Straight and Elbow Designs

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

Influence of Exhaust Throttling of 3-Way Solenoid Valve on Actuator Return Speed

You May Interest In

Nov 13, 2025 Blog

What are pneumatic angle seat valves used for?

Nov 13, 2025 Blog

How to check valve seat angle?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap