Sep 19, 2025

The pneumatic turbine vibrator is a type of pneumatic vibrator. It is driven by compressed air to rotate the turbine at high speed, generating centrifugal force that produces vibration.

In several common manufacturing sectors, pneumatic vibrators are a cost-effective and efficient solution. These industrial vibrators operate with lower noise, typically require minimal maintenance, and use compressed air, which is a common power source in many manufacturing plants.

Certain pneumatic vibrator models can be applied in challenging environments, such as freezing or high-temperature industrial settings, as well as dry, dusty, and humid environments.The turbine type offers many advantages compared with the ball and piston types.

High Efficiency and Low Energy Consumption

The turbine structure enables fast startup, strong and consistent vibration, and higher efficiency. Compared with ball and piston pneumatic vibrators, it requires less air consumption.

Low Operating Noise

The turbine design eliminates metal-to-metal impact, ensuring smooth and quiet operation. In contrast, the steel balls in ball vibrators roll at high speed in their tracks, and the reciprocating motion of piston vibrators both generate significant noise.

Maintenance-Free and Long Service Life

With no complex metal friction components inside, it operates simply with clean compressed air.

Extended Operating Cycle

It can withstand harsh environments and is unaffected by high or low temperatures, humidity, or dust, allowing stable operation even under extreme conditions.

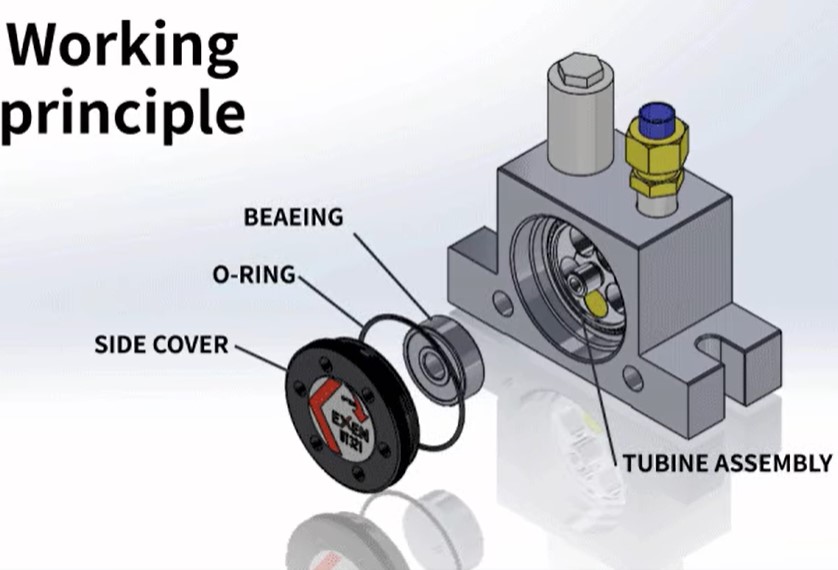

Side Cover

Mounted on the outside of the vibrator and fixed with screws. This component primarily serves to enclose the internal structure and ensure air tightness. It also provides mechanical protection, preventing dust and debris from entering.

O-Ring

Installed between the side cover and the housing. This component mainly provides sealing to prevent compressed air leakage and the ingress of fine dust, while also reducing friction between parts.

Bearing

Installed between the turbine assembly and the housing. This component mainly supports turbine rotation and reduces friction. The Fokca turbine pneumatic vibrator uses pre-lubricated sealed bearings, which allow long-term operation without the need for additional oiling.

Turbine Assembly

Located inside the vibrator. This component uses compressed air to drive the turbine at high speed. The turbine carries an eccentric mass, and when rotating, it generates centrifugal force. This is the principle of power generation in turbine pneumatic vibrators, and the vibration is ultimately transmitted to the mounted equipment or silo.

Housing/Body

This is the overall frame structure of the vibrator, carrying all components and providing mounting interfaces. It has air inlets and outlets to control the inflow and outflow of compressed air.

Turbine pneumatic vibrators, with their high frequency, low amplitude, clean operation, and quiet performance, are suitable for industrial applications involving free-flowing materials such as powders and fine granules.

Prevent bridging and rat-holing: Avoid powder or granular materials in silos and hoppers from getting stuck and failing to discharge.

Improve material flowability: Suitable for flour, cement, sugar, chemical raw materials, and more.

Assist in discharge: Help containers and packaging machines discharge materials smoothly.

Pneumatic Piston Vibrator

Its working principle is that the piston reciprocates within the cylinder and strikes the base plate, generating concentrated vibrations to achieve efficient material conveying.

The advantage of this type of piston vibrator is that it prevents clogging, ensuring smooth flow of materials in hoppers, bins, and screens.

The piston vibrator is suitable for materials that are semi-wet, wet, or sticky.

Ball-type pneumatic vibrators

Their working principle involves a piston inside the cylinder propelling steel balls to roll at high speed and strike the base plate, generating a more powerful impact force than turbine-type vibrators, enabling efficient material conveyance.

The advantages of ball vibrators lie in their concentrated impact force and high vibration frequency, which effectively prevent material clogging and ensure smooth material flow in silos, hoppers, and screens.

Ball vibrators are suitable for powdered, granular, and moderately viscous materials.

You May Interest In

Dec 02, 2025 Blog

What are the parts of a pneumatic cylinder?

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap