What is a pneumatic knocker?

The key feature of the impact hammer lies in its pneumatic drive. It provides a strong magnetic field and pulverizing effect. Low air consumption, low operating cost, and energy efficiency are among its advantages. The impact interval can be adjusted. It offers consistent standards and a low failure rate. With a unique style and simple layout, it resists piston effects and features a modern appearance.

Features

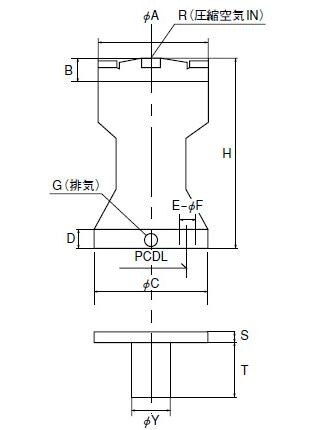

The following diagram shows the structure of a pneumatic hammer. Compressed air enters through port R, pushing the internal piston in linear motion, striking the bottom mounting surface. This direct impact produces a strong impact vibration. Finally, the exhaust gas is discharged through port G.

R:

This is the air inlet, connected to the compressed air pipeline. Compressed air enters the device through this port to drive the internal piston.

G:

This is the exhaust port. When the piston completes its movement, the air is discharged from here.

Overall Dimensions

φA, φC, φY:

These represent the outer or installation diameters, used for model selection and installation alignment.

H:

The overall height of the device.

PCDL:

Indicates the pitch circle diameter of the mounting bolt holes, used for flange fastening.

B, D, E, F, S, T:

These are detailed dimensions for actual mechanical installation.

Fokca manufacturer

The pneumatic hammer is one of Fokca's pneumatic products. In addition, we also offer pneumatic actuators, valves, pneumatic tubing, fittings, and other types of pneumatic equipment. We are dedicated to collaborating with customers worldwide in the field of industrial automation, helping to achieve precision machining and intelligent manufacturing. Visit our official website for more information, or contact us directly to obtain the latest prices and product details.