Why pneumatic products are so important for industrial automation

You know why trucks, buses, and other large vehicles are generally equipped with pneumatic braking systems to prevent brake failure caused by ruptured or leaking hydraulic lines. In these systems, the brake actuators are driven by compressed air, and even if the compressed air is lost, the automatic actuating device will still engage the brakes, ensuring the vehicle is brought to a stop.

What are pneumatic products? Pneumatic products equipments include various components used to generate, control, and distribute compressed air.These systems are commonly applied in automation, manufacturing, and industrial processes to ensure smooth and efficient operation.

Essential conditions for pneumatic product automation

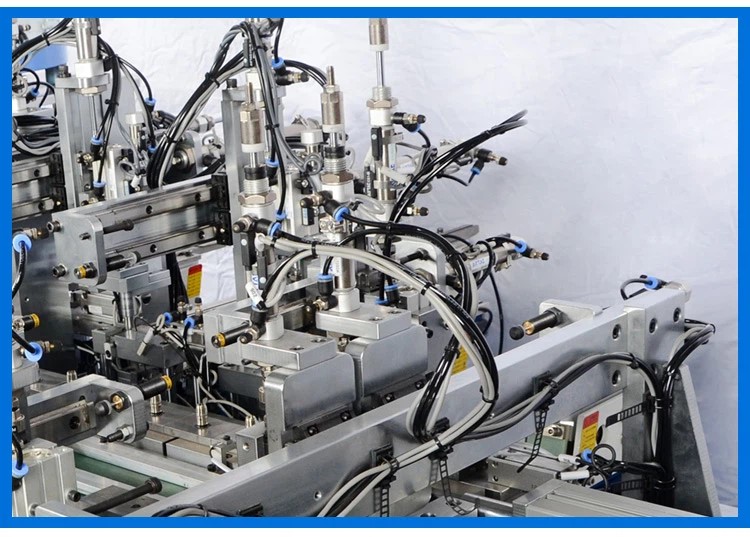

Pneumatic products use compressed air as a power source to convert air energy into mechanical energy. Different types of pneumatic components work together to perform the functions of the system. In the process of realizing automation in pneumatic systems, sensors and control systems are indeed two essential elements.

The operator only needs to set a predetermined value in the control system, and then the system can automatically issue control commands based on the feedback from the sensors. The sensors detect parameters such as the position, pressure, speed, and stroke of cylinders or actuators, enabling the control system to send continuous control signals. Under the combined action of sensors and the control system, pneumatic valves and actuators can operate automatically.

The Can Crusher Machine is a typical example of pneumatic automation device. In automatic mode, it can automatically detect whether a can is properly positioned, drive the cylinder to perform compression, and then retract the piston rod to prepare for the next cycle.

Pneumatic automation products include

Pneumatic components are defined as parts in a pneumatic system that use compressed air to perform motion, control, and other functions. They are characterized by simple design but standard, high reliability, and the ability to operate in harsh environments. Specific products include the following:

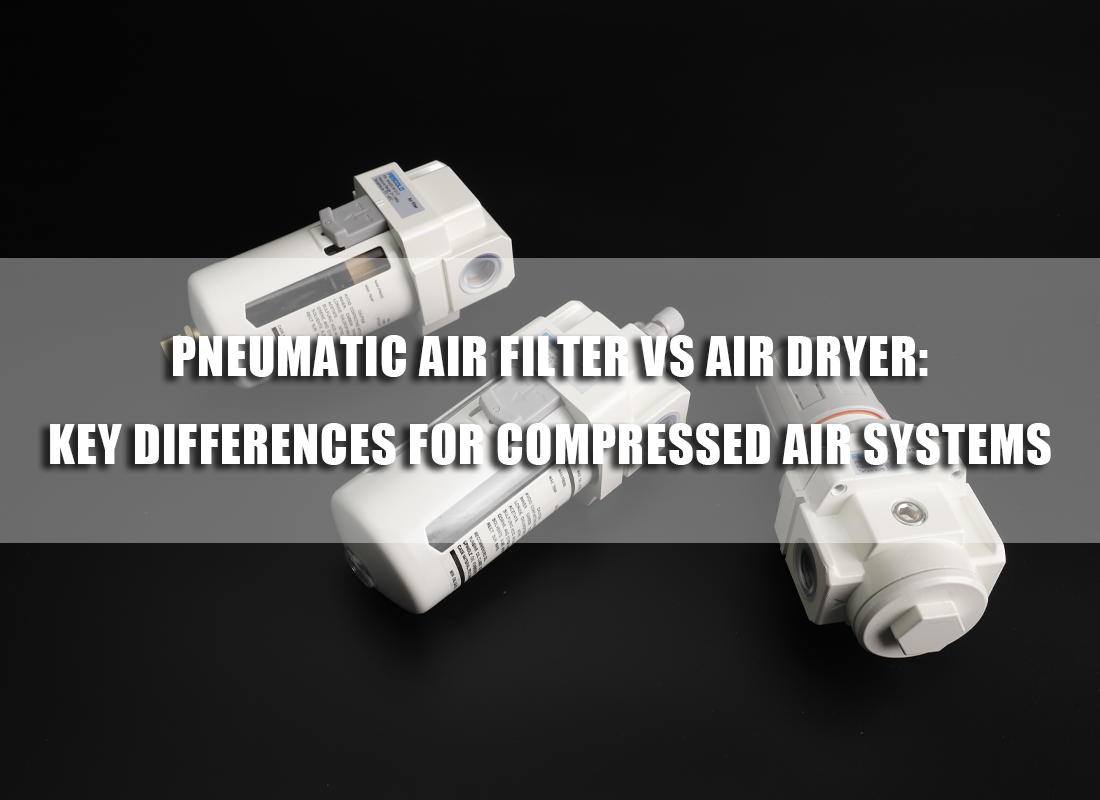

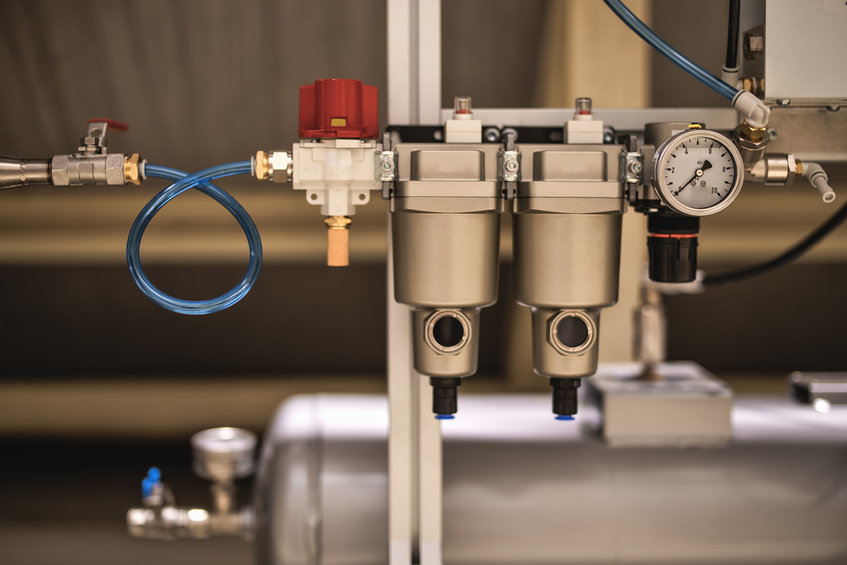

◆ Air Preparation Components

Relevant pneumatic products include air filters, pressure regulators, lubricators, and air preparation units (FRL). They primarily provide clean, dry, and stable compressed air for the pneumatic system.

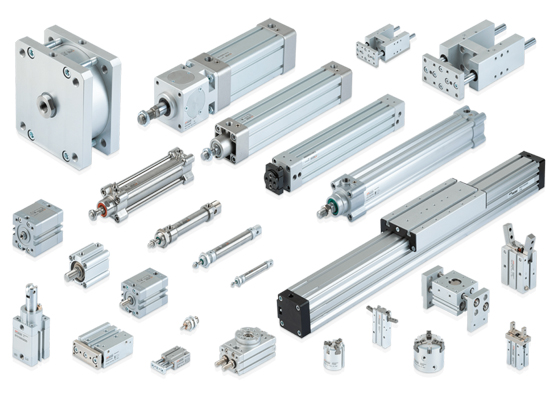

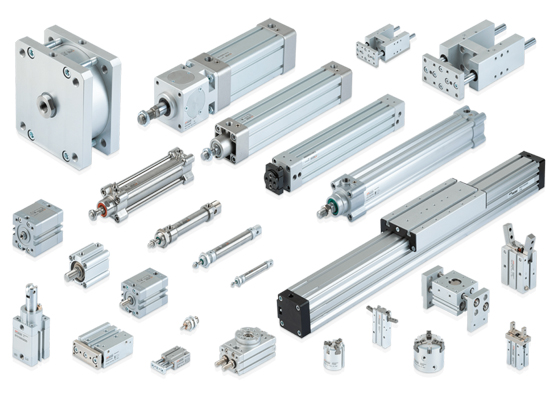

◆ Actuating Components

These are air-driven automation products, including cylinders, pneumatic motors, pneumatic vibrators, and pneumatic hammers. They are the core parts for energy conversion in a pneumatic system and can work with solenoid valves and sensors to achieve closed-loop automatic control.

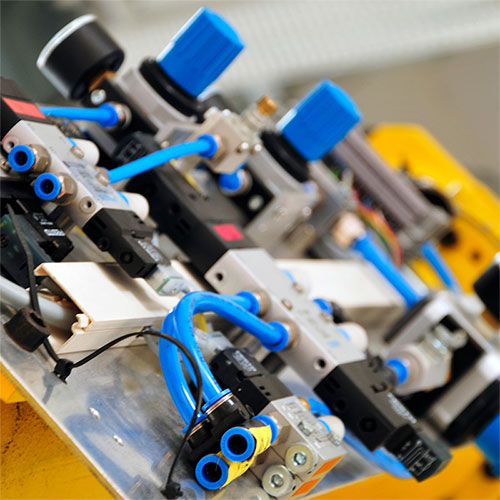

◆ Control and Regulation Components

Pneumatic valves mainly control the direction, flow, and pressure of airflow, enabling precise movement or operation. They include regulating valves, diaphragm valves, solenoid valves, and mechanical valves. Some valves mainly function to start or stop the flow of the fluid medium, such as angle seat valves, pneumatic ball valves, axial flow valves, and safety valves, which protect the overall system.

◆ Connection and Auxiliary Components

These components ensure reliable connections between pneumatic elements and facilitate the transmission of the fluid medium. They include air tubing, fittings, clamps, quick connectors, and air tanks.

◆ Detection and Feedback Components

These are mainly used to monitor the status of the pneumatic system and enable automation and safety control. They include pressure sensors, position switches, and flow meters.

Main Features of High-Quality Pneumatic Products

When choosing pneumatic products, consider the following features:

◆ Durability and Strength

High-quality pneumatic products are made from materials and designed to withstand high pressure and harsh industrial conditions.

◆ Precise Control

Valves, regulators, and actuators ensure precise control of airflow, optimizing the efficiency of automated systems.

◆ Versatility

For applications requiring broader functionality, pneumatic components should support conditions such as digital remote logic control.

◆ Energy Efficiency

Pneumatic systems make efficient use of compressed air, ensuring maximum efficiency in air transmission across components, thereby reducing energy consumption and operating costs.