What Are Pneumatic Components?

Pneumatic components refer to the fundamental parts used in pneumatic systems for controlling, regulating, and executing operations that convert air energy into mechanical work. Individually, these components often cannot complete complex tasks; therefore, according to their functions in handling compressed air, categories of Pneumatic Components:

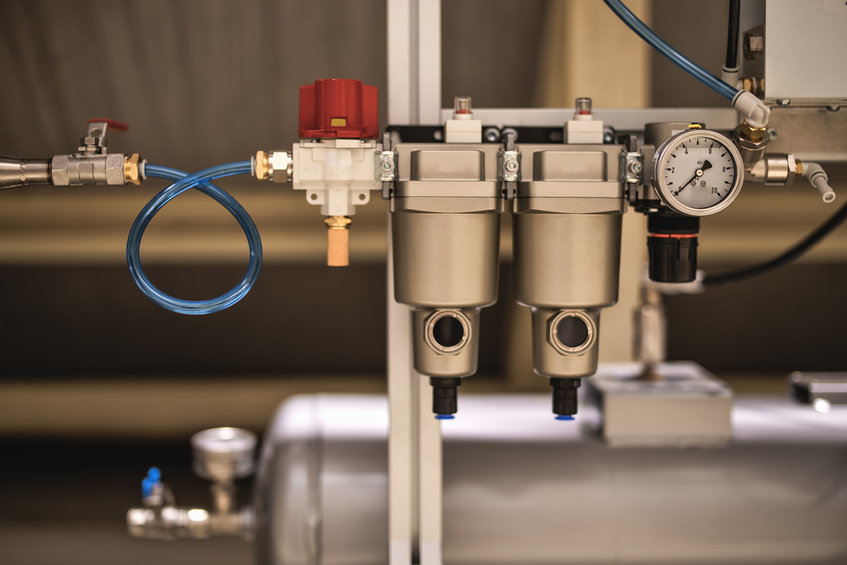

Air preparation components

Distribution and control components

Actuating components

Transmission components

Sealing and sensing components

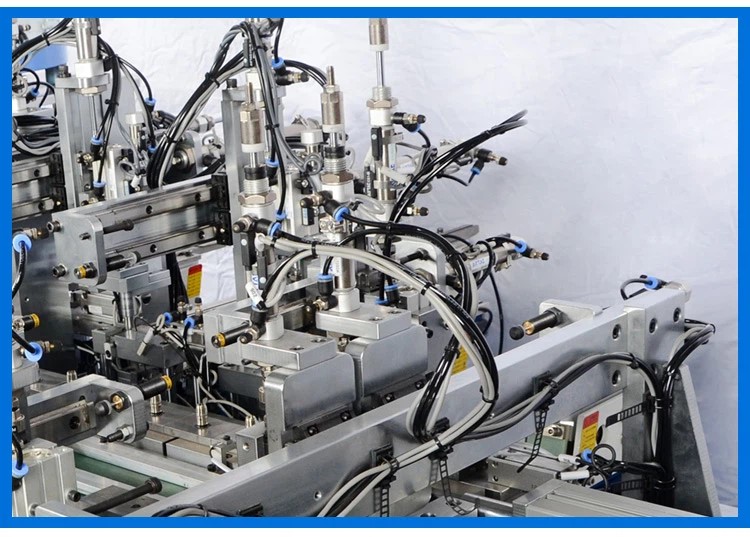

A few basic pneumatic components can be combined to form a simple pneumatic system, which is then capable of performing continuous mechanical operations that single components alone cannot achieve. Pneumatic components are characterized by simple structure, high efficiency, operational stability, cleanliness, environmental friendliness, easy maintenance, and strong interchangeability. They play a crucial role in applications requiring continuous, regular, and frequent mechanical motion.

If compressed air is considered the energy carrier of pneumatic technology, then the basic pneumatic components are the elements responsible for transmitting and processing the fluid medium.

What Is an Air Powered Device?

A pneumatic device is a type of equipment or machine that uses compressed air as its main source of energy. It is usually composed of multiple pneumatic components—such as valves, actuators, and air treatment units—which are combined to form a small pneumatic system capable of performing specific mechanical actions.Why Pneumatic Devices Are Widely Used in Automation:

They can be remotely controlled through electrical or pneumatic signals.

They can be equipped with sensors to monitor position and operating status.

They offer fast response speed.

Their operation is clean and pollution-free.

They are highly reliable and suitable for long-term continuous operation.

Essentially, a pneumatic device represents the practical application of pneumatic technology, where multiple basic components work together to achieve automated, precise, and repeatable control among pneumatic parts without the need for manual operation.

Differences Between Pneumatic Components and Pneumatic Devices

Item

| Pneumatic Components | Pneumatic Devices |

| Definition | Basic units of a pneumatic system used for processing and controlling air | A complete device composed of multiple pneumatic components |

| Function | Single functions, such as filtering air or generating linear motion | Performs a complete automated action |

| Ability to Work Independently | No

| Yes |

| Applications | Basic elements such as cylinders, valves, and tubing | Pneumatic clamps, pushing mechanisms, sorting systems, etc. |

| Automation Capability | None | Yes |

6 Key Conditions Essential for Achieving Automation in Pneumatic Equipment

◆ Stable and clean compressed air supply:Air source treatment unit

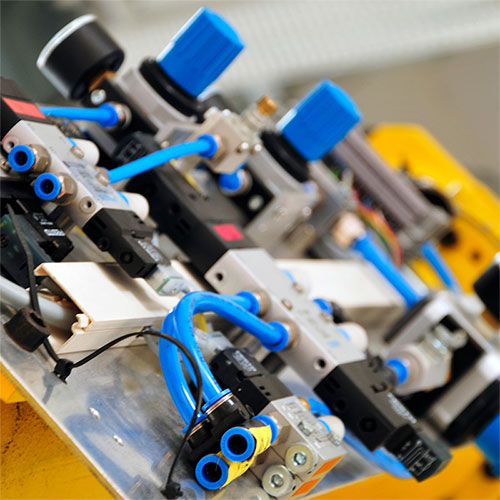

◆ Precise control system:Air valves

◆ State sensing and feedback mechanism:Reed switch sensor

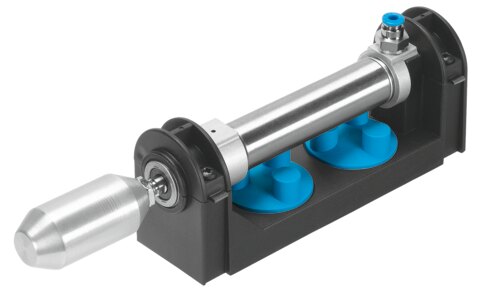

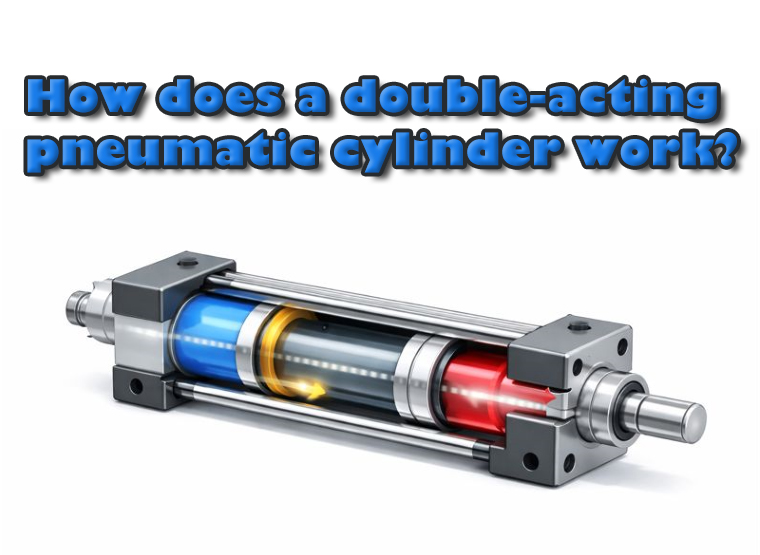

◆ Efficient coordination of actuators:pneumatic air cylinder

◆ Rational system integration and piping design:Hose and fittings

◆ Safety and protection mechanisms:Pneumatic muffler and safety valve

These different types of pneumatic components are the fundamental and essential elements for enabling proper operation and automation of pneumatic devices.

Closed-Loop Process

An automated closed-loop cycle begins with the control system sending a signal that activates the solenoid valve to switch the airflow direction, allowing compressed air to enter the piston cylinder and drive the piston into motion. The sensor then detects the position of the piston's movement and sends this feedback signal back to the control system. Based on the feedback, the control system determines whether the action has been completed; if it is normal, the next command (such as cylinder retraction) is issued, while in case of an abnormality, the system triggers an alarm or stops operation. Finally, the cylinder returns to its initial position, the solenoid valve resets, and the system returns to standby mode.

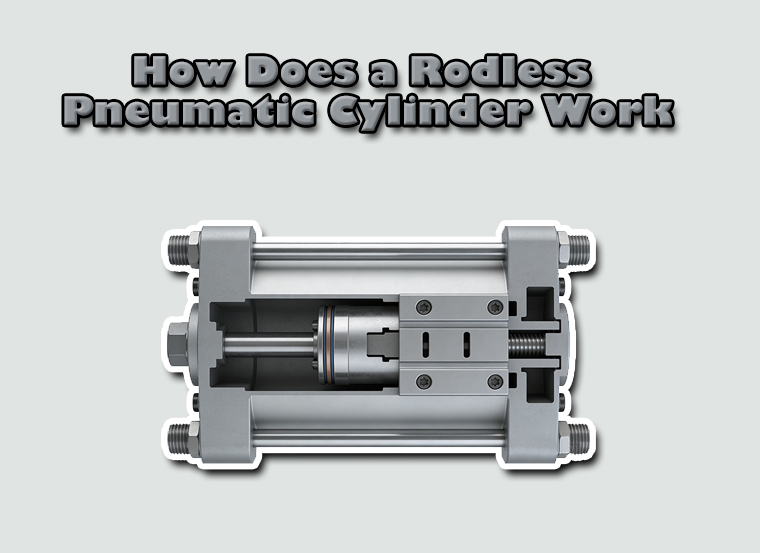

Pneumatic Components Provided By Fokca

Fokca provides a wide range of basic pneumatic components, including various types of cylinder actuators such as guided cylinders, rodless cylinders, rotary cylinders, and mini cylinders from brands like SMC and Airtac.Our pneumatic transmission components include tubing made from materials such as polyurethane, polyolefin, nylon, PVC, and fluororesin. We also supply a variety of fittings from SMC and Festo, available in materials such as stainless steel, brass, and nickel-plated stainless steel.

In addition, we offer a full range of valves, including solenoid valves, pressure regulators, pneumatic ball valves, axial valves, diaphragm valves, and globe valves.Other available products include cylinder mounting accessories and air preparation units.

If you have any requirements or inquiries, please feel free to contact us directly.

We also have experience in customized procurement of pneumatic products, including the customization of long-stroke cylinders for trucks, anti-rotation cylinders equipped with guide rails, and several other tailor-made pneumatic solutions.