Sep 30, 2025

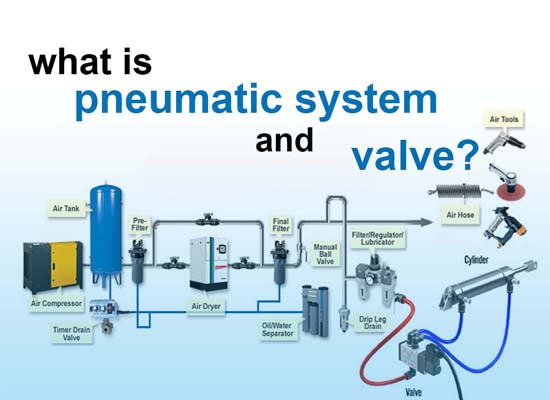

Pneumatic automation equipment is a combination of various components that use compressed air as the power source. It functions as a pneumatic system to achieve specific system objectives and mechanical motion tasks, making it the most direct application case of pneumatic technology.

A simple pneumatic system can be built with only basic air supply components, actuating components, and control and transmission components.

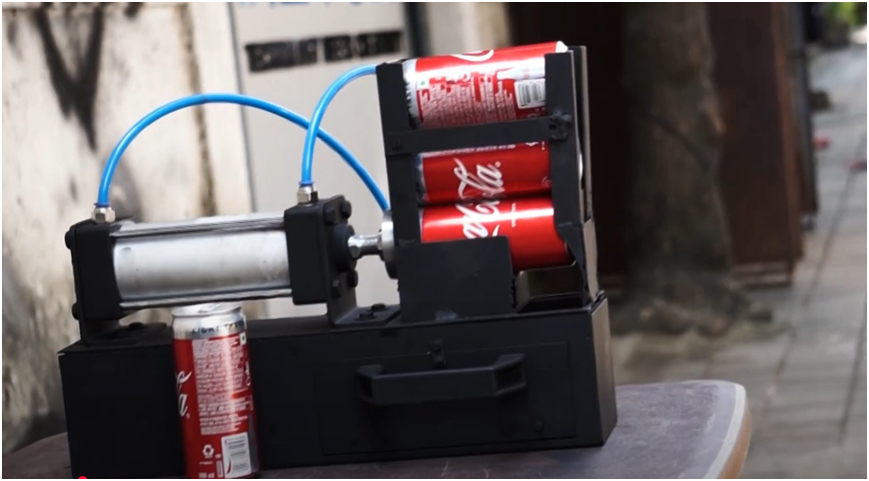

With the development of smart manufacturing, pneumatic automation systems are now deeply integrated with sensors, position detection, and remote control technologies.The can crusher machine is a simple example of a pneumatic component automation model.

For a long time, people have used manual can crushers to compress used cans. Crushing cans by hand is a difficult and very labor-intensive process. Therefore, we propose a pneumatic-based can crushing system that enables fully automatic can compression.

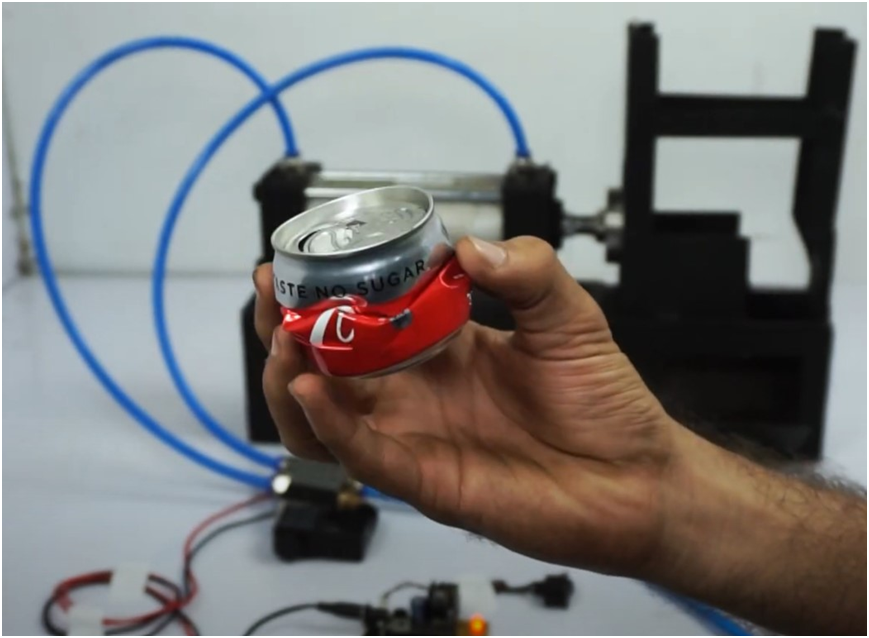

The can crusher can compress cans and metal tins with a capacity of up to 30 liters, reducing their volume by up to 90%. This compact and durable crusher contains no electrical components, making it easy to maintain and clean. It can compress almost all types of non-aerosol cans, including metal, steel, tin, and aluminum, with a maximum capacity of 30 liters. Whether in food production or manufacturing processes, many cans and metal tins contain waste liquids, such as oil, paint, or water, the handling of which is both troublesome and costly.

Pneumatic Actuator: Provides the linear crushing force needed to compress the can using compressed air.

Pneumatic Pipes: Deliver compressed air from the air source to the cylinders and valves within the system.

Pneumatic Fittings: Connect and seal the pneumatic pipes and components to ensure stable airflow without leakage.

Pneumatic Valves: Control the direction, pressure, and flow of air to operate the actuator precisely.

Supporting Bed: Holds the can in place during the crushing process to ensure stable and effective compression.

Crushing Bed: Serves as the surface against which the can is crushed when the actuator pushes it.

Supporting Frame: Provides the structural foundation that holds all machine components securely.

Mounts & Joints: Securely attach moving parts and components, allowing smooth motion and proper alignment.

Can Tray Assembly: Guides cans into the crushing area and positions them correctly for automated operation.

Electronic Circuit: Controls the automation sequence, sensor signals, and valve activation for the entire crushing cycle.

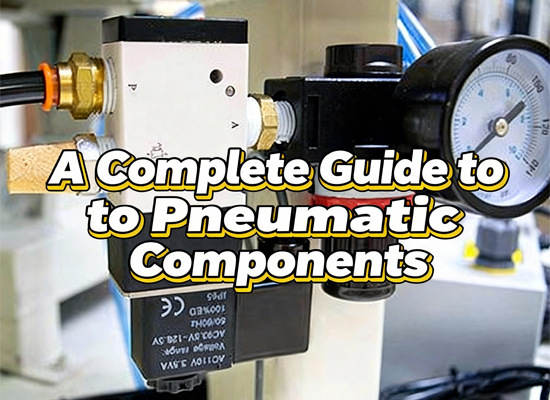

These different types of pneumatic components are the fundamental and essential elements for enabling proper operation and automation of pneumatic devices.

Automatic Can Crushing

The pneumatic can crusher operates fully automatically, eliminating the need for manual labor. Users can compress cans effortlessly, improving workplace efficiency and reducing fatigue.

Efficient and Consistent Compression

The system delivers uniform crushing results every time, reducing the volume of cans by up to 90%. This consistency ensures optimal space utilization in waste management and recycling.

Easy Waste Handling

By compressing metal, steel, tin, and aluminum cans—even those containing residual liquids—the crusher simplifies waste disposal. It minimizes mess, reduces handling costs, and streamlines recycling or waste processing.

Fokca is a pneumatic product manufacturer offering a wide range of products, a high level of standardization, and a strong global service network. With 50 years of experience in automation and pneumatic technology, the company provides integrated electric and pneumatic control systems. Its business spans multiple fields, including fluid control, sealing systems, pneumatics, and hydraulics. Fokca specializes in pneumatic components and systems, offering products such as cylinders, directional valves, pressure control valves, solenoid valves, fittings, and more. If you are interested in collaboration, please contact us directly.

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

You May Interest In

Apr 18, 2025 Blog

What Is Pneumatic System And Valve?

Sep 22, 2025 Blog

What are pneumatic automation products?

May 06, 2025 Blog

A Complete Guide to Pneumatic ComponentsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap