Sep 30, 2025

Pneumatic devices refer to various tools and instruments that generate and utilize compressed air.

Pneumatic devices are not uncommon in our daily lives. They feature relatively simple structures and high reliability, and under continuous compressed air supply they can perform high-frequency cyclic actions, making them highly suitable for automation applications.

Other common pneumatic devices include rock drills, pavement breakers, riveting machines, forging presses, spray guns, sandblasters, and atomizers. Automation equipment plays a crucial role in reducing manual labor, improving efficiency, and making our lives more convenient, healthy, safe, and environmentally friendly.From the following article to learn how these pneumatic device achieves efficient power output in various industrial scenarios.

Pneumatic devices include pneumatic components. Each type of pneumatic device uses compressed air as the power source and, through different mechanisms, achieves functions such as rotation, impact, or cutting.Behind them all lies a stable pneumatic system that plays a role as a whole.

The pneumatic hammer also can be called a pneumatic air knocker. It is hand-held by an operator, who presses the trigger to supply air. Compressed air is delivered through air hoses to the handle of the hammer. The operator controls the airflow into the cylinder via the trigger valve, which drives the piston in a reciprocating motion. When the valve is closed, the exhaust air is released.

Features:

It has no automatic logic; the timing of the strikes is entirely determined by the operator.

It is not an automated device.

Operation: Once air is supplied, the turbine vibrator automatically generates vibration, without requiring continuous manual operation.

Features:

It can be part of an automated pneumatic system, but requires sensors, solenoid valves, and a control system to work together for automated operation.

Operation: The operator places the can → presses a button or foot switch → the cylinder compresses the can → releases to reset.

Features:

The compression action is performed automatically through the pneumatic circuit, but manual triggering and feeding are required.

It is considered a semi-automated pneumatic device.

Through examples of different types of pneumatic equipment, we can see the wide application of pneumatics technology in modern manufacturing. To achieve automation, a complete closed-loop control system is required.

Workflow:

A photoelectric sensor detects that a can has been placed in the compression position → sends a signal to the PLC.

The PLC controls the solenoid valve → the cylinder descends to compress the can.

Once compression is complete → a limit switch detects that the cylinder has reached its position → the PLC sends a signal to reverse the valve → the cylinder retracts.

The can is automatically ejected → the next can moves into position, and the cycle repeats automatically.

Features:

No manual button pressing required → the compression operation is completed automatically.

Can operate continuously → improving efficiency and reducing manual labor.

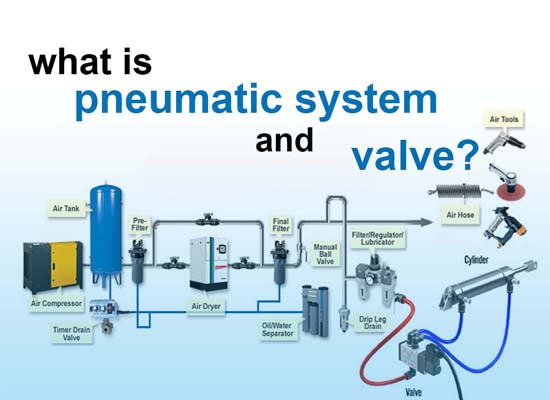

A pneumatic system is composed of various fundamental components, each with a specific role: cylinders convert the energy of air pressure into linear or rotary motion, performing pushing, pulling, clamping, and other actions; tubing and fittings transport the air and ensure airtight connections; valves control the direction, pressure, and flow of air, and in combination with solenoid valves, enable automated operation; air preparation units (filters, regulators, lubricators) ensure the air is clean, pressure-stable, and properly lubricated; cylinder mounting accessories are used to secure cylinders and adjust their position, ensuring reliable system operation. Working together, the entire system allows pneumatic devices to perform various mechanical actions efficiently and reliably.

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

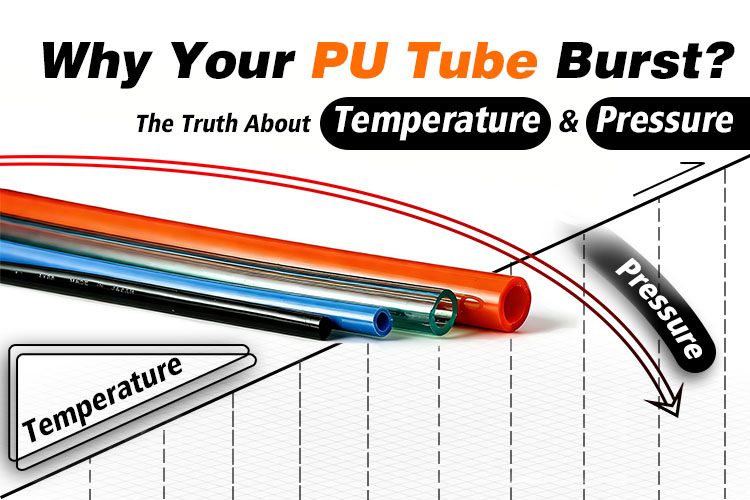

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

You May Interest In

Apr 18, 2025 Blog

What Is Pneumatic System And Valve?

May 06, 2025 Blog

A Complete Guide to Pneumatic Components

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap